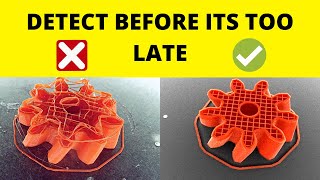

This study presents an open source method for detecting 3D printing anomalies by comparing images of printed layers from a stationary monocular camera with G-code-based reference images of an ideal process generated with Blender, an open source free physics rendering engine. Recognition of visual deviations was accomplished by analyzing the similarity of histograms of oriented gradients (HOG) of local image areas. The developed technique requires preliminary modeling of the working environment to achieve the best match for orientation, color rendering, lighting, and other parameters of the printed part. The output of the algorithm is a level of mismatch between printed and synthetic reference layers. Twelve similarity and distance measures were implemented and compared for their effectiveness at detecting 3D printing errors on six different representative failure types (local infill defects, presence of a foreign body in the layer, spaghetti problem, separation and shift of the printing part from the working surface, defects in thin walls, and layer shift) and their control error-free print images. The results show that although Kendall's tau, Jaccard, and Sorensen similarities are the most sensitive, Pearson's r, Spearman's rho, cosine, and Dice similarities produce the more distinguishable results. This open source method allows the program to notice critical errors in the early stages of their occurrence and either pause manufacturing processes for further investigation by an operator or in the future intelligent automatic error correction. The implementation of this novel method does not require preliminary data for training, and the greatest efficiency can be achieved with the mass production of parts by either additive or subtractive manufacturing of the same geometric shape. This open-source method has the potential means of enabling smart distributed recycling for additive manufacturing in challenging environments.

- Free and open source code: https://osf.io/q8ebj/

- https://arxiv.org/abs/2111.02703

- Blender

Highlights[edit | edit source]

- In-situ layer-wise 3D printing anomaly detection is based on reference images.

- G-code-based synthetic references are created in a physics rendering engine.

- The system analyzes the similarity of local histograms of oriented gradients.

- Failure detection resolution is 5-10% of the entire observation area.

- The method allows noticing critical errors in the early stages of their occurrence.

3-D printing, additive manufacturing; open-source hardware; RepRap; computer vision; quality assurance; real-time monitoring; anomaly detection; Blender; HOG; synthetic images

See also[edit | edit source]

- OS Computer Vision for Distributed Recycling and Additive Manufacturing

- Additional OS Computer Vision Applications

- Integrated Voltage—Current Monitoring and Control of Gas Metal Arc Weld Magnetic Ball-Jointed Open Source 3-D Printer

- Low-cost Open-Source Voltage and Current Monitor for Gas Metal Arc Weld 3-D Printing

- Slicer and process improvements for open-source GMAW-based metal 3-D printing

- Open-source Lab

- Open source 3-D printing of OSAT