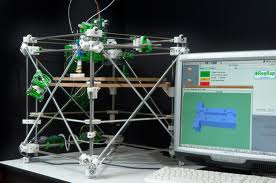

Mechanical testing of polymer components made with the RepRap 3-D printer

The purpose of this project is to determine mechanical properties of polymer components printed with the open source RepRap Mendel 3-D printer. Standard test methods are to be used to gather accurate and acceptable test data. The results of the mechanical testing will be used for engineering analysis of parts designed to be created with the RepRap.

The results are published here: B.M. Tymrak, M. Kreiger, J. M. Pearce, Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions, Materials & Design, 58, pp. 242-246 (2014). http://dx.doi.org/10.1016/j.matdes.2014.02.038. open access

Detailed coverage here:

- Mechanical Properties of Components Fabricated with Open-Source 3-D Printers Under Realistic Environmental Conditions

- The Effects of PLA Color on Material Properties of 3-D Printed Components

- Tensile Strength of Commercial Polymer Materials for Fused Filament Fabrication 3-D Printing

- Anisotropic mechanical property variance between ASTM D638-14 type I and type IV fused filament fabricated specimens

Testing Standards[edit | edit source]

ASTM D638-10 Standard Test Method for Tensile Properties of Plastics

Test Specimen[edit | edit source]

ASTM Type I specimen - STL file revised with starting point outside of specimen STL file

Printer settings to test[edit | edit source]

All g-code will be generated using Slic3r software from http://slic3r.org/

| Slic3r Setting | |

|---|---|

| Layer Height | 0.4mm, 0.3mm, 0.2mm |

| Fill Density | 1.0 |

| Fill Angle | 0, 45 |

| Fill Pattern | Rectilinear |

| Solid Fill Pattern | Rectilinear |

Test Equipment[edit | edit source]

- MTS Test System in M&M 413

- MTS Testworks Software on test machine computer

- Epsilon Technology 3542-0200-050-ST Extensometer

Specimen to Test[edit | edit source]

Naming Protocol[edit | edit source]

Layer Height-Orientation-Fill-Print#-Source

ie. (3-90-100-1 MTU) for 0.3 LH, 90 deg Fill Orientation, 100% Fill, Print #1, at MTU

Base Testing[edit | edit source]

- 3 layer heights -.2,.3,.4; orientations 45, 90; 12 testing conditions; 10X each; 120 total tests.....

PLA

- 0.4mm 90 deg (10 printed) 45 deg (10 printed)

- 0.3mm 90 deg (10 printed) 45 deg (10 printed)

- 0.2mm 90 deg (10 printed) 45 deg (10 printed)

ABS

- 0.4mm 90 deg (10 printed) 45 deg (0 printed)

- 0.3mm 90 deg (0 printed) 45 deg (0 printed)

- 0.2mm 90 deg (0 printed) 45 deg (0 printed)

See also[edit | edit source]

- Mechanical testing of 3D printed metal parts

- For electrical testing and for thermal conductivity:disc 2.5 inches in diameter that is 3.2 mm thick. 5X

- Viability of Distributed Manufacturing of Bicycle Components with 3-D Printing: CEN Standardized Polylactic Acid Pedal Testing

- RepRap Mechanical Testing Literature Review

- MOST RepRap Build

- Open source rapid prototyping of OSAT

- Life cycle analysis of distributed polymer recycling

- Applications of RepRap distributed production - literature review

- Recyclebot

- RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament

- Tensile test protocol: MOST

- Fused Particle Fabrication 3-D Printing: Recycled Materials' Optimization and Mechanical Properties

- Chemical Compatibility of Fused Filament Fabrication-based 3-D Printed Components with Solutions Commonly Used in Semiconductor Wet Processing

- 3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing

- Mechanical properties of 3-D printed truss-like lattice biopolymer non-stochastic structures for sandwich panels with natural fibre composite skins