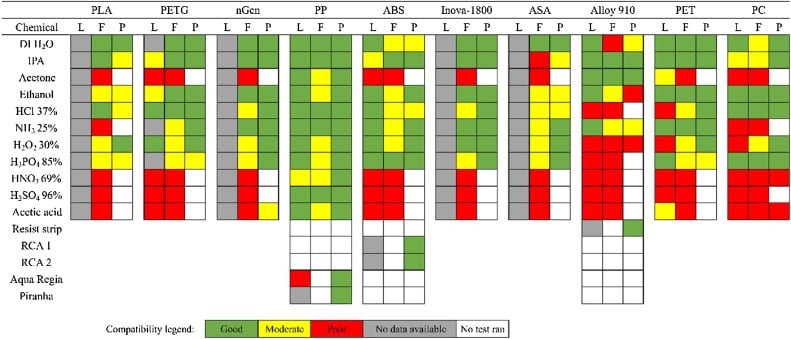

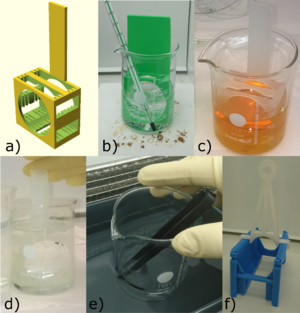

3-D printing shows great potential in laboratories for making customized labware and reaction vessels. In addition, affordable fused filament fabrication (FFF)-based 3-D printing has successfully produced high-quality and affordable scientific equipment, focusing on tools without strict chemical compatibility limitations. As the additives and colorants used in 3-D printing filaments are proprietary, their compatibility with common chemicals is unknown, which has prevented their widespread use in laboratory chemical processing. In this study, the compatibility of ten widely available FFF plastics with solvents, acids, bases and solutions used in the wet processing of semiconductor materials is explored. The results provide data on materials unavailable in the literature and the chemical properties of 3-D printable plastics that were, are in line with literature. Overall, many 3-D printable plastics are compatible with concentrated solutions. Polypropylene emerged as a promising 3-D printable material for semiconductor processing due to its tolerance of strongly oxidizing acids, such as nitric and sulfuric acids. In addition, 3-D printed custom tools were demonstrated for a range of wet processing applications. The results show that 3-D printed plastics are potential materials for bespoke chemically resistant labware at less than 10% of the cost of such purchased tools. However, further studies are required to ascertain if such materials are fully compatible with clean room processing.

- Source files- Included SCAD and STL files for the designs tested are in the attached zip folder.

The SCAD file for the dippers is in the zip. That dipper is a remix of Toffe’s original, https://3dprint.nih.gov/discover/3dpx-008194. The original jig handle by Z. Liu is here https://3dprint.nih.gov/discover/3DPX-008165 The tweezers were found on Thingiverse, Desktop_Makes: Tweezers. 3-D model, available: https://www.thingiverse.com/thing:1783167. Accessed March 7, 2018.

Keywords[edit | edit source]

3-D printing,chemical compatibility, semiconductor wet processing, custom labware, clean rooms

Key Findings[edit | edit source]

See also[edit | edit source]

- Understanding the multilevel phenomena that enables inorganic atomic layer deposition to provide barrier coatings for highly-porous 3-D printed plastic in vacuums

- Compatibility of 3-D printed devices in cleanroom environments for semiconductor processing

- Thermal Post-Processing of 3-D Printed Polypropylene Parts for Vacuum Systems

- Mechanical Properties of Components Fabricated with Open-Source 3-D Printers Under Realistic Environmental Conditions

- The Effects of PLA Color on Material Properties of 3-D Printed Components

- Open source rapid prototyping of OSAT

- RepRap Mechanical Testing Literature Review

- Environmental life cycle analysis of distributed 3-D printing and conventional manufacturing of polymer products

- Recyclebot

- Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament

- Mechanical testing of polymer components made with the RepRap 3-D printer

- Development and feasibility of applications for the RepRap 3-D printer

- Life cycle analysis of distributed polymer recycling

- Solar powered distributed customized manufacturing

- Life cycle analysis of distributed polymer recycling

- Tensile Strength of Commercial Polymer Materials for Fused Filament Fabrication 3-D Printing

- Approaches to Open Source 3-D Printable Probe Positioners and Micromanipulators for Probe Stations

- Vacuum Outgassing Characteristics of Unpigmented 3-D Printed Polymers Coated with ALD Alumina

In the News[edit | edit source]

- Experiment Tests the Suitability of 3D Printing Materials for Creating Lab Equipment 3DPrint 39k

- Research finds 3D printed chemically resistant labware viable with low-cost printers 3D Printing Industry 78.3k, 3D Print Home, 3D Print.In

- Analysis finds 3D printed chemically resistant labware viable with low-cost printers Junkies Tech

- Experiment Tests the Suitability of 3D Printing Materials for Creating Lab Equipment 3DPrint

- 3D-printed tools welcome Cleanroom Technology

- Research finds 3D printed chemically resistant labware viable with low-cost printers Microfabricator