The road to wisdom? — Well, it's plain and simple to express: Err and err and err again but less and less and less. Piet Hein

Academic and Professional Background[edit | edit source]

A Ph.D. candidate at Michigan Technological University specializing in computer vision in additive manufacturing with in-depth knowledge of pattern recognition and texture analysis, as well as hands-on experience in object segmentation and point cloud processing. Strong background in embedded sensor systems and motor control.

Completed Bachelor's program in Robotics and Master's program in Physics and Mathematics. I am highly passionate about combining advanced computer vision and augmented reality technologies with intelligent sensor systems in solving manufacturing problems.

Research Interests[edit | edit source]

- Computer vision | Deep learning

- Augmented reality | Visual servoing

- Robotics | Embedded Systems

- Additive manufacturing | CNC and 3D printing

- Open-source hardware and software

Publications[edit | edit source]

- A.L. Petsiuk, J.M. Pearce. Open source filament diameter sensor for recycling, winding, and additive manufacturing machines. ASME. J. Manuf. Sci. Eng. 2021, 143(10): 105001. https://doi.org/10.1115/1.4050762.

- A.L. Petsiuk, J.M. Pearce. Open source computer vision-based layer-wise 3D printing analysis. Additive Manufacturing 2020, 36, 101473. https://doi.org/10.1016/j.addma.2020.101473.

- A.M. Pringle, S.W. Oberloier, A.L. Petsiuk, P.G. Sanders, J.M. Pearce. Open source arc analyzer: multi-sensor monitoring of wire arc additive manufacturing. HardwareX 2020, 8, e00137. https://doi.org/10.1016/j.ohx.2020.e00137.

- A. Petsiuk, N. Tanikella, S. Dertinger, A. Pringle, S. Oberloier, J. Pearce. Partially RepRapable automated open source bag valve mask-based ventilator. HardwareX 2020, 8, e00131. https://doi.org/10.1016/j.ohx.2020.e00131.

- A.L. Petsiuk, J.M. Pearce. Low-cost open source ultrasound-sensing based navigational support for the visually impaired. Sensors 2019, 19, 3783. https://doi.org/10.3390/s19173783.

- S.S. Sule, A.L. Petsiuk and J.M. Pearce. Open Source Completely 3-D Printable Centrifuge. Instruments 2019, 3(2), 30; https://doi.org/10.3390/instruments3020030.

Projects[edit | edit source]

Computer vision-based layer-wise 3D printing analysis[edit | edit source]

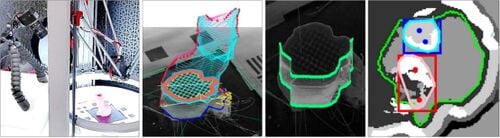

The layer-wise 3D printing analysis is built upon multiple-stage monocular image examination, which allows monitoring both the external shape of the printed object and internal structure of its layers. Starting with the side-view height validation, the developed program analyzes the virtual top view for outer shell contour correspondence using the multi-template matching and iterative closest point algorithms, as well as inner layer texture quality clustering the spatial-frequency filter responses with Gaussian mixture models and segmenting structural anomalies with the agglomerative hierarchical clustering algorithm. This allows evaluation of both global and local parameters of the printing modes.

A.L. Petsiuk, J.M. Pearce. Open source computer vision-based layer-wise 3D printing analysis. Additive Manufacturing 2020, 36, 101473. https://doi.org/10.1016/j.addma.2020.101473.

Filament diameter sensor for recycling and winding machines[edit | edit source]

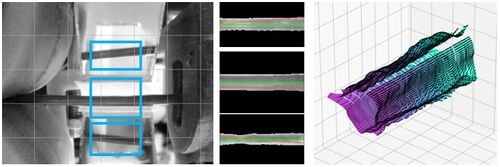

The modular system for multi-axis optical control of the diameter of the recycled 3D-printer filament makes it possible to scan part of the surface of the processed filament, save the history of measurements along the entire length of the spool, as well as mark defective areas.

A.L. Petsiuk, J.M. Pearce. Open source filament diameter sensor for recycling, winding, and additive manufacturing machines. ASME. J. Manuf. Sci. Eng. 2021, 143(10): 105001. https://doi.org/10.1115/1.4050762.

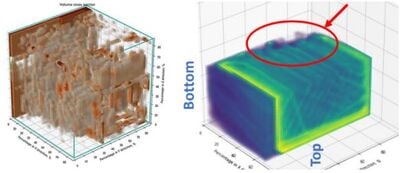

Texture analysis: histogram similarity metrics[edit | edit source]

Layer-wise analysis of 3D printing quality based on histogram similarities.

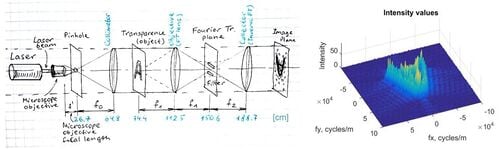

Analog image processing (4F optical correlator simulation)[edit | edit source]

A Matlab simulation for a 4F Correlator system is based on the Fourier transforming properties of lenses. The 4F Optical Correlator system is based on the Fourier transforming properties of lenses. According to the Diffraction theory, a convex lens of focal length f will produce the Fourier transform at a distance f behind the lens of an object placed at f distance in front of the lens. These properties give us an opportunity to implement direct and inverse Fourier transforms of two-dimensional objects, modify and analyze their spatial frequency spectra.

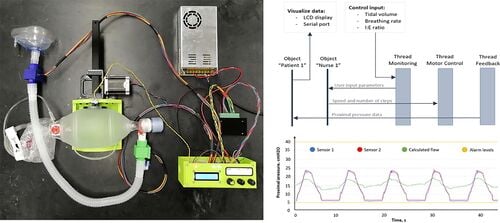

Bag valve mask-based ventilator[edit | edit source]

The resuscitation system is based on the Arduino controller with a real-time operating system installed on a largely RepRap 3-D printable parametric component-based structure. The device provides a controlled breathing mode with tidal volumes from 100 to 800 mL, breathing rates from 5 to 40 breaths/minute, and inspiratory-to-expiratory ratio from 1:1 to 1:4.

A. Petsiuk, N. Tanikella, S. Dertinger, A. Pringle, S. Oberloier, J. Pearce. Partially RepRapable automated open source bag valve mask-based ventilator. HardwareX 2020, 8, e00131. https://doi.org/10.1016/j.ohx.2020.e00131.

[edit | edit source]

The system conveys point-distance information by utilizing the natural active sensing approach and modulates measurements into haptic feedback with various vibration patterns within the four-meter range.

A.L. Petsiuk, J.M. Pearce. Low-cost open source ultrasound-sensing based navigational support for the visually impaired. Sensors 2019, 19, 3783. https://doi.org/10.3390/s19173783.

Appropedia page OSF Repository Video

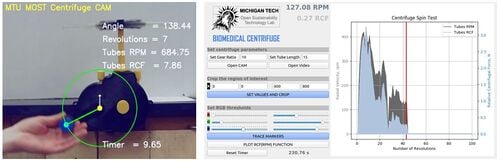

Centrifuge monitor[edit | edit source]

As the working part of the centrifuge rotates at a speed of up to 2000 rpm, it may be difficult to track its motion, since the majority of regular web cameras operate at a frequency of 25–30 Hz. Thus, as the whole system represents a mechanical transmission with the fixed gear ratio, an indirect method was chosen to calculate the angular velocity of the tubes based on the speed of rotation of the centrifuge handle.

S.S. Sule, A.L. Petsiuk and J.M. Pearce. Open Source Completely 3-D Printable Centrifuge. Instruments 2019, 3(2), 30; https://doi.org/10.3390/instruments3020030.

Michigan Tech's open-source community[edit | edit source]

Michigan Tech's home for all things free and open source.

FFT sound analysis

Web weather monitor

Solar panels

Co-authors – Collaborators[edit | edit source]

| Dr. Joshua Pearce | Shane Oberloier | Samantha Dertinger | Nagendra Tanikella |

| Dr. Mazher Mohammed | Adam Pringle | Koami Hayibo | |

| Dr. Paul Sanders | Pierce Mayville | Rachel Dick |