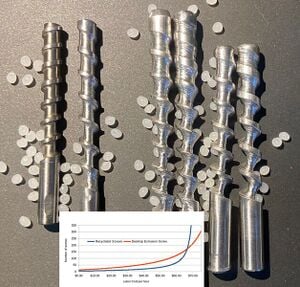

Making the Tools to Do-It-Together: Open-source Compression Screw Manufacturing Case Study

A remaining challenge to enable free and open-source hardware (FOSH) to catch up with now industry-dominant free and open-source software (FOSS) is identifying appropriate business models. In this article a new FOSH business model is discussed, specialty components for fabricators, using a case study of an open-source screw manufacturer business. The case study explores the economics of building a system that is meant to fabricate a specialty component for other businesses and prosumers working in the distributed recycling and additive manufacturing (DRAM) space. The component payback time is calculated under various scenarios, the sales necessary to provide an enticing income for a small business is quantified, and the point at which business expansion is necessary is determined. The results indicate that, to serve the burgeoning DRAM market, more than 1,000 small businesses could follow a Do-It-Together (DIT) approach of sharing FOSH designs while manufacturing and profiting locally.

See also[edit | edit source]

- Emerging Business Models for Open Source Hardware

- Global value chains from a 3D printing perspective

- Sponsored Libre Research Agreements to Create Free and Open Source Software and Hardware

- Economic Savings for Scientific Free and Open Source Technology: A Review

- Quantifying the Value of Open Source Hardware Development

- Open-source, self-replicating 3-D printer factory for small-business manufacturing

- Strategic Investment in Open Hardware for National Security

- Towards national policy for open source hardware research: The case of Finland

- Professors Want to Share: Preliminary Survey Results on Establishing Open Source Endowed Professorships

- Canadian professors’ views on establishing open source endowed professorships

- Open source decarbonization for a sustainable world

- Equitable Research Capacity Towards the Sustainable Development Goals: The Case for Open Science Hardware

- Business Models for Open Source Hardware Repositories