Low cost Sun Tracker for Solar PV powered Vaccine Refrigerator

Vaccine Storage & Handling Toolkit, May 2014[edit | edit source]

This CDC guide tells us that the refrigerator we will be using for vaccine storage should not be dormitory type of refrigerator/freezer. The refrigerator we would use should be standalone refrigerator and maintain temperature between 35°F and 46°F (2°C and 8°C). Setting the average temperature around 40°F (5°C) and maintaining(stabilizing) it around that value is important. Freezing will damage the vaccines, so using standalone freezer which maintains temperatures between -58°F and +5°F (-50°C and -15°C) is recommended.

Medical Refrigeration[edit | edit source]

Medical refrigeration is essential to keep the medicines in good condition. Conventional refrigeration technique is not very good solution for medical refrigeration because conventional refrigerators don't maintain a uniform temperature in all different areas of the freezer or refrigerator. Without good refrigeration temperature(ideally should be 4°C) the medicines won't have potency to immunize or prevent the diseases. It will result in a life potentially lost.

Importance of maintaining cold chain cool[edit | edit source]

While transportation of medicine and vaccine, it is very important to keep the temperature cold between 2°C and 8°C with low electricity supply and in varying temperature conditions. Due to lack of good cooling system for vaccine and different whether during travel reports indicate that 75-100% of all vaccine shipments are compromised, immunization programs fail and countless lives are lost.

Storage temperature of water[edit | edit source]

Before and since the mechanical refrigeration technology was invented ice has been in common use for preventing food spoilage. For the perfect storage solution the water should be kept near +4°C to make sure living organisms and fish could stay alive. Density of water is the maximum at the temperature of +4°C and is equal to 999.9720 Kg/m3. As water has maximum density at 4°C of temperature it sits at the bottom of lake and the warmer or colder water then stays on top of it. Frozen ice is 0°C which floats on the layers of water having descending temperatures from 4°C to 0°C. If the water is warmer than 4°C the warmer water stays on top of water at the temperature of 4°C at the bottom.

Improving the cold chain in developing world[edit | edit source]

Vaccine is powerful health tool which saves around 3 million lives every year. Millions of dollars are spent by organizations like GAVI, UNICEF and Gates Foundation on vaccine programs every year. For all immunization and vaccine programs maintaining the cold chain is most important thing. All the vaccines except oral polio vaccine(OPV) should be kept between 2°C and 8°C. WHO has a set of standards known as Performance Quality Safety(PQS) that cold chain equipment should confirm to before it should be procured by NGOs and Ministries of Health. Technologies used in off-grid vaccine refrigeration includes absorption refrigeration, ice-lined mains powered refrigeration and solar powered vaccine refrigerators with battery storage.

Absorption technology has fuel supply problem if the fuel runs out then the vaccines become warmer because of high temperature. It also needs human intervention to check the temperature is maintained inside the storage compartment frequently, which is very inconvenient normal condition and worst in emergency. Ice-lined refrigeration is not suitable because it needs constant power supply. So, if power runs out storage compartment gets warmer. Another problem is different areas of the refrigerator do have different temperature in these kind of refrigerator. So, it needs just one compartments that maintains the temperature between 2°C and 8°C, doing that is not easy with these kind of refrigerators. Solar powered vaccine refrigerators which uses battery to store the power gets exposed to high temperature when battery fails.

True Energy Ltd. did a very good job by developing Sure Chill® vaccine refrigerator. There are two versions of these refrigerators. One is solar powered version and other is mains powered version. It requires only 4 hours of solar irradiation or mains power supply in a day to operate effectively at an ambient temperature of 46°C and 2.5 hours at 32°C. Moreover it can maintain internal temperature at favorable point for 247 long hours without power supply which is referred as holdover time(time for which compartment can maintain temperature below 10°C). It is energy efficient as it uses 1.00 - 1.15 kW/h per day at 43°C once internal energy store is fully charged. Temperature variation in the compartment is less than 0.5. It doesn't freeze vaccines or medicines so risk is eliminated.

The refrigerator works on patented technology which uses the principle that water is at its densest at 4°C. The water jacket around the storage compartment helps in maintaining the temperature around 4°C(typically between 2°C and 8°C). Water at 4°C stays at the bottom of water jacket and at the top the water freezes to ice which prevents the water down form freezing and provide perfect temperature condition to the compartment. So, no matter what are the external temperature the refrigerator maintains a good temperature in compartment for vaccine storage.

Rechargeable Lithium ion Battery and Charging[edit | edit source]

Lithium ion batteries provide twice the power than Nickel-cadmium and four times the lead acid batteries. The only problem is that these kind of batteries require voltage level, temperature and current monitoring circuits during charging and discharging for safety and protection from damage. So, depending on the application appropriate charge controller and monitoring device should be used or built by the hardware developer. Battery run time and charge time depends on the battery power pack, system output and input requirement.

Why use Li Batteries[edit | edit source]

All kind of fuel cells and batteries are electrochemical storage devices. Batteries replace mechanical power systems which uses fossil fuel. So by replacing mechanical power systems with batteries we can make the earth carbon dioxide foot print as less as possible. The only problem with using the batteries is its low energy output capacity as compared to mechanical systems. But Li batteries have higher energy storage capacity than other kind of batteries. Also research on increasing the energy density of Li batteries is actively going on using some novel methods discussed in this paper. With solid state Li-ion batteries based on either dry polymer or inorganic electrolytes and nano structuring of ion conducting polymer membrane the safety of the battery can be improved with high energy systems also. The cost of the batteries is dependent upon the material-synthesis process, its abundance and renewability. Also the raw material should be cost effective to process. The electrodes are produced using bio mimetic process which are cost effective. Li-ion battery technology is green and sustainable because of the fact that the electrodes made by the organics material which has low CO2 footprint while recycling can even further reduced in the future. Manufacturing Li-ion batteries with electrodes designed from nano-composites/nano-architectures by using rapid screening of new catalysts having special shape, structures and morphology, has succeeded in preparing electrodes that show 1000 mAhg-1 capacity which is 6-8 times more than today's electrodes and have less CO2 emission.

Maximizing capacity of battery pack by cell balancing[edit | edit source]

The capacity of the battery degrades over the time if the energy storage capacity of one of the battery is lower than the other. If the capacities of the batteries are matched then the battery pack can maintain maximum power. In battery pack the cell are connected in series and if the individual capacity of the batteries mismatch then overall storage capacity degrades over the time. Battery pack capacity could reduce by 13 - 18 %. To maintain the capacity of individual battery, the voltages across the batteries should be monitors and then if there is difference between then then a shunting circuit activates and tries to minimize the difference between charging and discharging voltages over different charging discharging cycles. A decent amount of cell balancing is anywhere from 10% - 20%. Using cell balancing technique improves the capacity of battery pack with the system run time and life of the battery pack.

Battery state-of-charge determination and their application[edit | edit source]

State-of-charge is another problem which should be taken care of with over voltage protection and deep discharge. Detecting state-of-charge gives us idea of how long do we have the device to stop working. The SOC is defined as "the ratio between the difference of the rated capacity and the net amount of charge discharged from a battery since the last full SOC on the one hand, and the rated capacity on the other hand". This means the state has reached full SOC when (according to DIN 43539)the battery current is not changing during 2 hour at constant charge voltage and constant temperature.

Methods of determining the state of charge

Discharge test under controlled condition: This is too time consuming for most of the application because it include consecutive recharge.

Ampere hour counting

This is the most common technique for calculating SOC. Maximum power can be maintained by balancing the battery current. If a starting point (SOC0) is given, the value of the current integral is a direct indicator for the SOC. Current loss calculation has to be taken into account while calculating Ampere hour counting. This method is low cost method and useful for PV applications.

Measurement of the electrolytes physical properties

Only vented lead-acid battery could use this method. The relationship between the change of acid density and the SOC can be used to determine the SOC. The density could be measured directly or indirectly by ion-concentration, conductivity, refractive index, viscosity, ultrasonic, etc. This method has some maintenance problems so its not a good idea to use it for PV application.

Open Circuit Voltage

This is usually used for VRLA batteries. Open circuit voltage relates in a linear manner to SOC. This measurement is done during the rest period. Rest period is when the battery is not charging or discharge, so it doesn't happen quite often in VRLA batteries and has to be combined with other SOC measurement techniques. But the problem is VRLA batteries also need monitoring of acid concentration and acid stratification which can generate inaccurate results. Other drawback is rest time could be so long that SOC monitoring could be almost meaningless.

Heuristic interpretation of measurement curves

There are several heuristic methods discussed in this paper but Artificial neural network method is the one which could be used with any type of battery and application given that training data for the net is available. So every time the error should be calculated between training data and measured data to know the battery SOC.

Impedance spectroscopy

This method compares the measured impedance with the Nyquist plot available for the lead-acid battery. The impedance depends on temperature and if the temperature is maintained in favorable condition then only this method is good to use. Because of this it is not a widely used method and not good for PV systems.

Internal resistance

The internal resistance is the voltage drop divided by the current change during the same (short) time interval which should be less than 10ms. If the interval is increased then impedance spectroscopy has to be used for good measurement which is not a good option for variable temperature environment application.

Kalman filters

A Kalman filter is an algorithm to estimate the inner states of any dynamic system by doing repeated measurements rather than relying on a single one. In our case, the battery is the dynamic system and one of the inner states is the SOC. This method is good for PV system if the measurements are done using appropriate circuit.

Solar photo voltaic charging of lithium-ion batteries[edit | edit source]

The high system efficiency can be achieved by directly charging the battery from the PV system with no intervening electronics, and matching the PV maximum power point voltage to the battery charging voltage at the desired maximum state of charge for the battery.

On site solar direct current charging

System Efficiency = PV efficiency x DC charging efficiency.

If more circuitry is added to the system then efficiency of new added circuit gets multiplied in the system efficiency equation which makes efficiency lower because the added circuit can't have 100% efficiency due to power usage.

Solar energy to battery charge conversion efficiency

| in % | Solar energy to battery charge conversion efficiency |

|---|---|

| Efficiency = | (average voltage(V) x Charge increase(Ah))

(avg. solar irradiance(W m-2) x PV area(m2) x time interval(s) x 1/3600(sh-1)) |

Example Calculation

| in % | Charge Efficiency |

| Efficiency = | 100% x 0.5 x (V2 + V1) x (Charge2 - Charge1)

([time between V1 and V2(s)]/3600s h-1 x PV area(m2) x time interval(s) x 1/3600(sh-1)) |

Lithium-ion capacitor[edit | edit source]

Lithium-ion capacitor

| Specific energy | 11–14 W·h/kg |

| Energy density | 19–25 W·h/L |

| Specific power | 160–2800 W/kg |

| Charge/discharge efficiency | 95% |

| Self-discharge rate | < 5%/month (temperature dependent) |

| Cycle durability | >10,000 |

| Nominal cell voltage | 2.2–3.8 V |

Lithium-ion capacitors can be used for solar power, wind power and other power generation projects.

Lithium-ion battery[edit | edit source]

Lithium-ion battery

| Specific energy | 100–265 W·h/kg or (0.36–0.95 MJ/kg) |

| Energy density | 250–620 W·h/L or (0.90–2.23 MJ/L) |

| Specific power | ~250-~340 W/kg |

| Charge/discharge efficiency | 80 - 90% |

| Energy/consumer-price | 2.5 W·h/US$ |

| Self-discharge rate | 8% at 21 °C, 15% at 40 °C, 31% at 60 °C(per month) |

| Cycle durability | 400–1200 cycles |

| Nominal cell voltage | NMC 3.6 / 3.7 V, LiFePO4 3.2 V |

Solution for refrigeration[edit | edit source]

Sun Frost refrigerator Runs on either 12 volt or 24 volt DC. Uses fewer solar panels and batteries to purchase, transport, and install. It has rugged construction which means it is mechanical shock proof and has whether proof insulation. Cabinet is rust proof because it is made of all copper cooling system which prevents corrosion. Defrosting is easy, temperature control is excellent and compressor is only moving part. It runs only runs only 27% of the time in a hot 43° C (110° F) environment. Most efficient DC vaccine refrigerator in its size range. With no poser it could run for 9 days.

Price tag is $2,335.00. But it comes with full battery storage and solar panel. Installation help is also provided. Good thing is that it is approved by World Health Organization.

Sure chill ultimate tech solution

| Specifications | ||

|---|---|---|

| MODEL | BLF 100 AC (Mains) | BLF 100 DC (Solar) |

| Size (cm) | W: 89cm, D: 76cm, H: 185cm | W: 89cm, D: 76cm, H: 185cm |

| Gross storage capacity (litres) | 124L | 124L |

| Vaccine storage capacity (litres) | 99L | 99L |

| Holdover time 43°C | 250 hours(>10 days) | 184 hours(>7 Days) |

| Holdover time 32°C | 309 hours (>12 days)* | 288 hours (12 days)* |

| Power consumption | 43°C < 4 hours supply per day 32°C < 2½ hours supply per day |

Solar array 200W to 370W depending on geographical location |

| Minimum rated ambient temperature | 10°C | 5°C |

| Refrigerant | R134a (CFC free) |

R600a (CFC/HFC free) |

| Insulation | CFC/HFC free | CFC/HFC free |

| PQS code | E003/013(WHO) | E003/019(WHO) |

Sure chill is bigger than Sun Frost and holdover time is also greater than Sun Frost. But the cost is of Sure Chill is more than double as compared to Sun Frost $5,077. Though if we compare the volume then Sure Chill is more than 4 times the size of Sun Frost. So Sure Chill is more Efficient and cost efficient. But if we need small refrigerator then Sun Frost is a better choice.

Low cost vaccine refrigeration

- -[1]

Following are the normal refrigerators which are designed to maintain the temperature between 2℃ - 8℃ and use 60Watt - 70Watt power.

| Specification | |

|---|---|

| BT-5V48 | MPC-5V48 |

| 2℃ - 8℃ | 2℃ - 8℃ |

| 48/62 litre | 48 litre |

| Pharmacutical Freezer/refrigerator | Pharmacutical Freezer/refrigerator |

Both these refrigerators cost around $300. Both of them do not run on DC power. They only perform good with constant supply. These type of refrigerators need to be monitored constantly, so both have high and low temperature alarm system. These require lot more power than Sure Chill or Sun Frost and are not certified by WHO for maintaining the cold chain.

Battery Pack solution[edit | edit source]

Most of the refrigerator run on 12V DC. So there are various 12V batteries which are available in the market with different storage capacities. mAh is the measure of capacity of the battery. 2000 mAh battery means the battery will discharge a 2A of current over an hour of time. According to the specific PV application the battery required will be having different capacity. Battery cost ranges anywhere from $15 to $100.

The battery available on adafruit store gives 3.7 volt output with 2000mAh of capacity. It normally delivers 0.5 A of charge/discharge current and Charge cut off voltage for the battery is 4.2 V.

So there are plenty of options to select from in the market for choice of lithium-ion battery for low cost applications.

Hybrid Capacitor solution[edit | edit source]

Lanzar VCAP1200 Vector 12 Farad, 16 Volt Hybrid Capacitor is an example of the capacitor which could be used for power storage. The only thing one needs to keep in mind is super capacitors/hybrid capacitors can store less amount of power as compared to lithium-ion batteries or any other battery type. So power storing capacitors are only good for the application where one needs low power/small current and relatively fast discharge than lithium ion batteries. If someone still wants to use capacitors because of its compatibility to their application, but needs more power then number of capacitor/capacitor banks being used should be increased. Using capacitors is not cost efficient in PV systems. But if cost is not a problem then it is a good option.

Increase Solar Charging With An MPPT Power Tracking Charge Controller[edit | edit source]

Solar panels are used to track sunlight and heat and output power in terms of voltage and current. This is a webpage which explains why MPPT is essential to use in a battery charger. When we track sunlight using solar panel the heat and solar energy are trapped in solar cells and it gives rise to voltage and current. The amount of current and voltage we are getting depends on whether conditions also. Colder the whether more input voltage will be required which means that with the changing input voltage requirement the input and output impedance has to be matched to get the max output power. So MPPT does the same thing it matches the input and output resistance/impedance to get the maximum power output of solar panel which is given as input to the battery.

Lithium-ion capacitors can be used for solar power, wind power and other power generation projects.

Solar charge controllers for Lithium-ion, NiMH, NiCad[edit | edit source]

This charge controller is a general hardware solution which can be used as solar power charger for different kind of batteries. It has a MPPT tracker and can be programmed for different charging applications. All monitoring conditions can be monitors from remote location as it can communicate via serial channel. The same serial channel can be used to program the controller. As the micro controller has ADC and digital input/output port/ports it can used to measure battery charge termination measurement, capacity testing, battery quality testing, electrolysis, sensor control, etc. Typical programming fees are $500 to $2000 depending on complexity and test requirements for a particular application.

| Input voltage | Output Voltage | Output Power |

|---|---|---|

| 8-48 volts nominal, higher range possible | 2 volts to 80 volts available | 30 watts, 50 watts or higher depending on design |

This is SEPIC(single ended primary inductor controller) topology DC/DC converter programmed to perform as a battery charger. It has low voltage cut-off and high voltage protection protection facilities on board. Single board costs $80. It has appropriate specifications for lead-acid battery chargers.

Solar tracking Concepts[edit | edit source]

Concepts on Solar Radiation

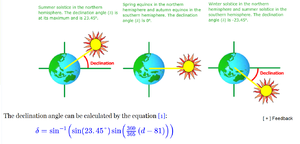

Declination Angle : The declination angle is the angle between the equator of the earth and a line drawn from the center of the earth to the center of the sun. The maximum declination angle is 23.45o on earth.The declination angle δ varies seasonally due to the tilt of the earth on its axis of rotation and the rotation of earth around the sun. The declination angle would be zero if the earth were not tilted. The declination angle varies between +23.45o to -23.45o. Only at equinoxes declination angle becomes zero.

Hour Angle : The hour angle is angular distance earth has rotated in a day. It is equal to 15o multiplied by the number of hours from local solar noon. Solar hour angle is zero when the sun is straight, negative before noon and positive after noon.

Solar Altitude(θZ) : The solar altitude is a vertical angle between the horizontal surface of earth and the line connecting to the sun. At sunrise and sunset the altitude is zero and is 90o when the sun is at zenith. Altitude relate to latitude of the site, declination angle and hour angle.

Solar Azimuth(θA) : The azimuth angle is the angle between the horizontal plane measured from true south or north. If someone lives in northern hemisphere and assuming zero azimuth to be south, azimuth will be negative before noon and positive after noon.

Single Axis and Dual Axis Tracker : Single axis tracker either tracks altitude or azimuth. Usually parabolic trough system tracks azimuth angle and rooftop system uses altitude tracking because lack of space. Other type of tracker is a dual axis tracker and tracks both azimuth and altitude angles of the sun.

Declination angle variation[edit | edit source]

For the calculation of the declination angle we have to consider that the earth is stationary and the sun is revolving around the earth. So for this type of calculation the co-ordinates have to be shifted under which the sun revolves the earth.

On summer solstice in the northern hemisphere the declination angle δ is at its maximum at 23.45o.

On spring equinox in northern hemisphere and autumn equinox in southern hemisphere declination angle δ is 0o.

On winter solstice in the northern hemisphere and summer solstice in the southern hemisphere declination angle δ is -23.45o.

Declination angle can be calculated by the equation :

δ = sin-1( sin(23.45o)sin((360/365)(d - 81)) )

where d is the day of the year with Jan 3 as d = 3. Power on the horizontal is maximum on day 81.[2]

Declination is zero at the equinoxes which come on March 22 and on September 22, positive during the northern hemisphere summer and negative during the northern hemisphere winter. The declination reaches a maximum of 23.45° on June 22 (summer solstice in the northern hemisphere) and a minimum of -23.45° on December 22 (winter solstice in the northern hemisphere).