Solar Tracking System Using Stepper Motor[edit | edit source]

This solar tracking system project was developed using ATMega16 microcontroller, LDR based maximum light intensity tracking and PV panel position control using Stepper Motors. Usually 30% to 60% increase in output power has been observed if the solar power system uses tracking as compared to the power system that doesn't use sunlight tracking. MPPT only tracks maximum output coming out of solar panel it can't help in getting more power input through out the day.

Light dependent resistors : There are two types of LDR CdS(cadmium sulfide) and GaAs(Gallium arsenide).LDR decreases its resistance as it is incident with light intensity. These sensors have saturation limit for light intensity. Beyond that light intensity LDR stops decreasing it resistance. Light intensity is measured in Lux, the illumination of sunlight is approximately 30,000 lux. Two such sensors had been used in this project to to track the sun light direction. If there is difference between the light intensity incident on both the resistors then the panel moves in the direction where it would get maximum light.

ATMEGA16 microcontroller : The micro controller has analog comparator inputs which can be used to compare the signals coming from the two LDRs and the output signal can be given to the stepper motor controller which generates logic sequence required for operation of stepper motor to be driven in particular direction.

Operation of the Solar Tracker : In normal day light condition the solar tracker will move from east to west. As 150o rotation is considered as maximum rotation, the micro controller will count 40 counts for 150o rotation and as soon as count becomes 40 the tracker stops rotating in west direction and rotates all the way to the 0o position. In bad whether condition, as the differential voltage doesn't go above the threshold, the micro controller is programmed to monitor this condition by checking the voltage every 1.5 minutes. Micro controller counts to 10 to make it 15 minutes and then rotates the panel through one step.

For protecting the PV panel surface from dust and avoiding the possible 50% loss of power because of dust the panels were fitted with brush rollers which would clean the surface twice during 24 hours every day. As this project uses single axis tracking, 20% increase in power was observed.

Motor selection for sun tracker[edit | edit source]

For solar tracking application the motors used has to perform good in all whether conditions and prevent any adverse effect like corrosion, wind loads and abrasive airborne particulate matter. Some of the modern motors also can communicate between them thereby reducing overall system cost and total cost of ownership (TCO).

Ac induction motors are not efficient and are very difficult to control at low speeds and that's why these motors are not used anymore after early solar tracking systems.

Stepper motors lose their economic benefits as we add more control components. Also there is an issue of motor binding because of very small air gap between stator and rotor if there is a temperature difference between them because of sunlight falling on some part of the motor. As the speed is limited there is problem with quickly moving panels in stowing position.

Permanent magnet brush dc motors (PMDC) have only one problem of brush or commutator wear. Its fast, controllable, efficient, and durable . Also good for stowing because wide range of speed.

Brushless dc (BLDC) motors have low TSO and maintenance free. No wear as it has no brushes for contacts. Highly efficient 85 - 90% and hits 3000 rpm which is advantageous in emergency stowing condition.

Various intelligent monitoring and control system can be integrated with BLDC for advanced, fast and efficient tracking systems using modern communication and networking methods.

Stowing the trackers in Winds[edit | edit source]

Solar trackers have to endure the effects of wind load in storms. The tracker structure may not have sufficient strength to withstand the elements, so its necessary to move and maintain a good stow position during winds.

Effects of Winds

In emergency high speed wind situation the solar panel boards can bend and result in less efficient or unusable system because of the different load condition on the edges of the solar panel board during the wind. Wind behavior tend to be varying depending on different fields where these panels are mounted.

The stow position

Theoretically effect of wind on a parallel plane is zero and the logical implementation of the board is in a horizontal position. But problem arises with this orientation because wind is not always horizontal. But because of wind at angle 20 to 30 degrees the dynamic pressure could be 105kg/m2 at 1.4 wind factor and 45kg/m2 at 0.6 wind factor on board's edges.

Panel weight and overall load

If the panel is placed as vertical as possible then panel weight becomes more equal on the surface and more endurable than in horizontal position.

Lower structure ensure the stability of the system with load but the tracking system should be able to go to more vertical position as possible. The solution for this is that the calculations must be performed keeping in mind the type of land , location, unique feature, unpredictable dynamics of wind, overall weight of system and structure design for a more stable system design which withstands the maximum wind condition.

Should we use ready made sun tracker for small application?[edit | edit source]

There are various micro controller based tracking solutions available in the market. Arduino Sun Hervester Shield V2 alone costs $55 which we have to use with arduino controller which costs around $25. Apart from this we need to buy motors and charger circuit or fabricate a charger circuit which would cost anywhere between $50 to $100 or more depending on particular application.[1] [2]

Obviously it doesn't make any sense to spend 100's of dollars if it is a small and simple application. If the system is more complex and multi tracker based system then using the above products could be sensible. Its always better to find some low cost alternative solution with simple electronic design with less complex circuit design which uses low power and is more efficient to use with PV system.

Reducing cost with low cost micro controllers[edit | edit source]

Arduino is an open-source electronics prototyping platform based on flexible, easy-to-use hardware and software. Lot of designers and hobbyists are using these micro controller boards. Developers can use these boards with arduino shield which are separate modules providing hardware capabilities like temperature sensing, wireless communication, etc. Using Arduino uno or Arduino pro would be a good option.

Arduino Uno costs $24.95 and Arduino Pro costs $14.95. Arduino Uno is faster but Pro which has 8Mhz speed is also enough fast for solar tracking application.

These boards can be programmed using Arduino IDE software. It is very easy to write programs using this software as wide range of libraries are available for various sensor applications. [3]

Low power, low cost micro controllers[edit | edit source]

MSP430 LaunchPad gives developers low cost low power option. These are very low power consuming processor boards with high speed processing micro controller boards. These processors are specially designed for applications like Energy Harvesting, Portable consumer, medical, security, Smart grid and sensor monitoring.

Energia is open source software to program MSP430 Launch Pad boards. It is very easy to use and has lot of online examples for coding and large library available.

Code Composer Studio (CCS) is TI's software development environment for writing and debugging programs on MSP430 Launch Pad. Code Composer Studio supports all of TI's embedded processing and debugging capabilities. Free evaluation versions are available for 30 day trials.

There are more software code compilers available namely IAR workbench, Keil, MSPGCC and Mentor graphics which are more like code composer than Energia.

MSP430 LaunchPad can be used with modules which add more hardware capability like wireless, LED lighting, etc. These modules are called as BoosterPacks.

MSP-EXP430G2 LaunchPad comes with internal temperature and smoke detectors. Its cost is just $9.99.[4] And it can be used with various kind of BoosterPacks.

H-Bridge DC motor driver[edit | edit source]

H-Bridge Drivers are needed for driving the motor in both the clockwise and anti-clockwise directions. It is possible because of the bi-directional current flow design of the circuit. The Leegoal L298N Stepper Motor Driver Controller Board Module comes with a price tag of $4.99.

H-Bridge consists of transistor switches which changes state between on and off to flow the current in particular direction.[5]

Low cost H-Bridge DC or 4 wire 2 phase Motor Driver[edit | edit source]

SODIAL(R) L9110S DC Stepper Motor Driver H-Bridge For Arduino 800mA 2.5-12v TTL/CMOS is a H-Bridge motor driver with a price of just $2.49. This module can simultaneously drive two DC motors or a 4-wire 2-phase stepper motor. Works under low static current which means it consumes low power. Power supply varies form 2.5 V to 12 V. Input levels match to TTL/CMOS output because of which it can be connected directly to the CPU. Which means no extra power consumption for power level conversion. Can drive 800mA of continuous current per channel. Compatible with low power micro controller boards.

Step towards low cost sun tracking[edit | edit source]

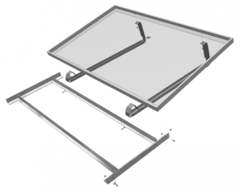

This solar tracker is good example for the power systems that could be used for portable power applications which require 12 volt range of power input. The support and the pivot are made of still and aluminum to make it low weight system. Stepper motors are used to move the PV panel support in particular direction. It uses worm gear system and timing belts for translating the rotating motion from small gear to bigger gear.

System uses LDR's to track the sun and orients the PV panal in the solar radiation direction. Arduino Uno has been used with power regulator, H-bridge driver ICs to get the operation of the circuit as expected for tracking the sun.

Structure design uses bar, plates and angle with some bearing for the support of the pivot. This is a dual axis tracker so it move in both Azimuthal and Zenithal direction. The weight of the tracker has been kept low so that the could have low specifications and would be cheaper. The system uses limit switches to turn off the rotation in E-W direction on both ends.

Solar Panel mount[edit | edit source]

- Because of its unique design and few installation steps installation time reduces significantly to half the time of competitive products.

- Requires only 7 parts to install and only 1 wrench required.

- It has flexible design to meet all weight, height and wide range of wind conditions

and accommodate majority of PV modules.

- Its is also highly compatible for roof mounting with or without penetrations.

- Design saves up to $10k on 250kw project.

Why use 3D printing[edit | edit source]

Contrary to traditional manufacturing technique where material gets subtracted from a block of material to form a design 3D printing uses additive manufacturing. 3D models are digital files so these could be sent anywhere around the world over the internet. On demand production can be done without inventory management. For printing new type of design each time no new setup is needed. It has a potential to reduce global economic imbalance as every country could produce their own products. As no fossils are used for 3D printing carbon footprint decreases which means 3D printing is completely green technology. Production and distribution de-globalizes as production is brought near to consumer. 3D printing reduces steps like casting, forming molding and machining which require computer and robots which is used in traditional manufacturing.

3D printing process: A 3D CAD model is prepared which then could be converted to a stereo lithographic file. A 3D stereo lithographic file can be sliced into layers. These layers then get printed using 3D printer which additively prints each layer on top of the earlier one to print a 3D object.

Disadvantages : Some of the 3D manufacturing methods require high powered energy sources e.g. metal 3D printing. Injection molding is quick and produces several objects while 3D printing takes longer time almost an hour to print 1.5 inch cube with good quality print. There is lack of good material and methods to produce objects with 3D printing which could have more strength and speed of production.

Advantages : Best option for rapid prototyping as it just require 3D modeling and printing. Lot of metal objects are being 3D printed using metal 3D printers which are fully functional design. So no need of extra processes. 3D printers are available for home now-a-days with a cost of under $1000 approximately. Very complex parts also could be printed with just one process. Digital design and manufacturing ensures overnight production without monitoring. Complexity is free, which means there is no extra cost for production for complex objects. Instant production anywhere in the world is possible. As this is a additive process it doesn't produce any waste once the printer is well calibrated.

Plastic 3D printed parts are much cheaper than metal 3D printed parts. So for applications where metal parts are not necessary plastic 3D printed part can be used as low cost solution. That way cost reduction for that part could be 80-90%.

Selection of Solar Panel[edit | edit source]

For high power application or low power applications using 30 Watt solar panel is better option. Reason for this is that the 30 Watt solar panel is best fit if we need to mount it in array because of its size and if it is considered for low power application then using a single 30 Watt solar panel is good option as it is light weight and gives significant power for household or portable applications. Following table shows the price comparison of the solar cells available in the market.

| Company name | Model name | Power(W) | Price($) |

|---|---|---|---|

| General Electric | GEPV-030-M | 30 Watt | Commercially available on contact ** |

| Suntech Power | Suntech STP030P | 30 Watt | $99.00 ** |

| Tektrum Development Corporation | HQRP | 30 Watt | $149.91 ** |

| Tycon Power Systems | TPS-24-30 | 30 Watt | $169.95 ** |

| British Petroleum | BP-330J | 30 Watt | $284.95 ** |

| Goal Zero | Boulder 30 | 30 Watt | $199.99 ** |

** Prices keep on changing.

Understanding Photovoltaics[edit | edit source]

There are two types of solar technologies concentrated solar power(CSP) and solar Photo voltaic technology. Solar photo voltaic is a popular technology based on photo diodes which produce power when hit by photons from sun whereas in CSP the solar heat is captured using parabolic reflectors and focused on the rod or pipe through which liquid flow and conduct heat to run the steam or gas turbines. Because the power can be produced in any scale it can be used for home utility and Grid like large applications and to small applications like mobile computing.

Currently 90% of the market is dominated by crystalline silicon solar cell. Its just a photo cell with larger photon receptor area which converts light into electrical energy. Maximum power of the PV is the product of Imax and Vmax. Maximum power point point is a point where the power(V-I) curve becomes squared for given irradiance.

Fill Factor, FF = A2/A1 see figure 4 in -- [6]

Efficiency = Pmax/Pein(light irradiated power) = (Voc x Isc x FF)/Pein

Cell Structures : These are multi-junction solar cells made by stacking individual single junction cells with the band-gap descending from the top to the bottom of the cell. Designing cells this way makes the highest energy photons absorbed by the top junction and the lower energy photons transmitted to be absorbed by the lower band-gap solar cells. Multi-junctions are usually built using compound semiconductor hetero-structures using III-V[7] and II-V materials. Concentrated PV are emerging cells which uses multi-junction with intensity 10-1000 times of traditional cells because of which it enjoys lowest cost per watt but currently costs higher. In future the cost of new systems will go down making $/W lesser and efficiency will increase.

Solar Panel Power Characteristics, Shading Effects and Tilt Angles[edit | edit source]

The current and power output of the solar panel depends on the internal resistance of the load and the intensity of the solar radiation. Depending on battery's internal resistance the operating voltage of the solar panel will change(lower) than the max voltage specification. The current will be the same always which the panel is suppose to produce, e.g. If the panel is 30 Watt panel, the current will be 1.5 ampere for both 20 V and 10 V output voltage producing 30 watt and 15 watt power.

PV panels face shading due to soft or hard sources like tree branch, roof vent, chimney or blanket, tree branch, bird dropping sitting directly on top of the glass. If even one full cell is hard shaded, the voltage of that module will drop to half of its un-shaded value in order to protect itself. If enough cells are hard shaded, the module will not convert any energy and will, in fact, become a tiny drain of energy on the entire system.

Partial shading will reduce its power output if even one cell on a 36-cell solar panel is soft shaded. As all cells are connected in series the total amount of power level will go down by the amount of powered reduced from the cell which is in shade.

When a full cell is shaded it consumes energy produced by rest of the cells on module. The solar panel will route the power(more specifically current) around that series string. If one full cell in a series string shades it will likely cause the module to reduce its power level to half of full power available. If a row of cells on the solar panel is fully shaded the power output may drop to zero because now the power on the solar panel is not enough to drive the current through the shaded region. The best way to avoid a drop in output power is to avoid shading whenever possible.

Carbon Fiber and ABS filament for 3D Prints[edit | edit source]

For 3D printing a new type of filament is available in the market produced by Filabot, made from two strong materials Carbon Fiber and ABS plastic, to make an even stronger combination. They mix a Carbon Fiber Masterbatch and our ABS pellets together to a 5% Carbon Fiber ration and extrude that into filament. Even better it still prints just the same as normal ABS.

Design and development of a low-cost solar tracker[edit | edit source]

This low cost solar tracker uses maximum power point tracking for maximum electrical output and sun tracker for maximum incident light through out the day which gives maximum overall efficiency for the solar power.

Crystalline silicon solar cells have theoretical maximum efficiency of 28%.

Sun Power Corp. has already achieved an efficiency of the panels of 24%.

Using MPPT increases the gained efficiency to about 20% - 30%.

Annual gains of energy of solar trackers over fixed panels are around 30% - 50% depending on the site of installation and type of tracker.

Photovoltaic Systems Maximum Power Point Tracking[edit | edit source]

1. Constant Voltage

The constant voltage measured which represents VMP is the simplest method. VMP value can be programmed by an external resistor connected to a current source pin of the control IC. In this case, this resistor can be part of a network that includes a NTC thermistor so the value can be temperature compensated(which means temperature variation won't have any effect on VMP measurement). This method can collect upto 80% of maximum power.

2. Open Circuit Voltage

This is indirect calculation of VMP by calculating VOC. The k value which is a function of the logarithmic function of the irradiance, increasing in value as the irradiance increases. The k value is typically between 0.70 to 0.80

VMP = k x VOC

Frequent VOC sampling helps in correcting its value with change in temperature and radiance.

3. Short Circuit Current

This is a similar method to Open Circuit Voltage only difference is voltage replaces current and k value varies from 0.9 to 0.98. IMP = k x IOC

This method uses a short load pulse to generate a short circuit condition. During the short circuit pulse, the input voltage will go to zero, so the power conversion circuit must be powered from some other source. One advantage of this system is the tolerance for input capacitance compared to the VOC method.

4. Perturb and Observe

Perturb and Observe (P and O) searches for the maximum power point by changing the PV voltage or current and detecting the change in PV power output. In this step size should be optimal so that it reaches the maximum power point quickly and stops perturbing soon.

5. Incremental Conductance

Incremental conductance (IC) locates the maximum power point when:

(dIPV/dVPV) + (IPV/VPV) = 0.

This condition simply states that the maximum power point is located when the instantaneous conductance,(IPV/VPV), is equal to the negative value of incremental conductance,(dIPV/dVPV). The IC uses a search technique that changes a reference or a duty cycle so that VPV changes and searches for the condition of above equation and at that condition the maximum power point has been found and searching will stop.When the left side of Equation 5 is greater than zero, the search will increment VPV. When the left side of above equation is less than zero, the search will decrement VPV. Incremental Conductance (IC) is good for conditions of rapidly varying irradiance. However, noise may cause continuous searching so some amount of noise reduction may be needed.

Combinations of above methods are good to use since only one method would not give the expected results.

How Buck Converter Works[edit | edit source]

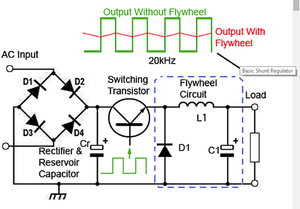

Buck converter is used to regulate/step down the voltage for the load. It can be used with AC/DC power supply. It uses bridge rectifier when the input is AC.

It uses MOSFET as a switch to allow the input voltage to go across the load. Load voltage is given as:

VOUT = VIN x (On time of switching waveform (tON) / periodic time of switching waveform(T))

During the time tOFF the stored power in the Inductor and Capacitor flow through the Load maintaining the voltage at a certain level and smoothing out the output voltage waveform using L-C filter. Output voltage can be varied by varying duty cycle of the PWM signal given to the MOSFET as bias.

The combination of the diode, inductor and capacitor is called as Flywheel circuit.

Current Sense Amplifier[edit | edit source]

Current sense amplifiers outputs a voltage proportional to the current flowing in a power rail. It utilizes a "current-sense resistor" to convert the load current in the power rail to a small voltage, which is then amplified by the current-sense amplifiers.

Current sensing of 1 A to 20 A can be done using current-sense resistor resistance range between 1 to 100 mΩ.

Voltages in the range of 10 to 100 mV can be sensed in the presence of very large common-mode voltages of 5 to 30 V.

Some current sensing amplifier are unidirectional sensors and some are bidirectional sensors.

Over voltage protection is necessary because if the voltage sensed is out of the range then the internal ESD protection diodes conduct high current and amplifier burns.

LTC6101, MAX4080, AD8210, TS1100, INA193 and MAX9938 are some examples of Current sense amplifiers.

Solar tracking power generator[edit | edit source]

This project discusses a new IR camera based tracking option for solar radiation tracking. By using special algorithm in MCU it can determine the location of the sun by analyzing the IR image. As soon as MCU knowns location of the sun it tracks the sun using azimuthal and altitudal position control motors. This method is the most accurate method and has no effect on sensing if the whether is cloudy. It could only be beneficial to use this method if it is light weight, power efficient and cost effective.

MPPT Algorithm: Perturb and observe method for MPPT tracking is used in this project which works well. For Monitoring the current, voltage and temperature sensors are used. This sensed values also improve efficiency of the PV system. Different testing methods have been used to measure the efficiency, tracking system performance, MPPT tracking performance, etc.

Wireless connectivity for the Internet of Things[edit | edit source]

For maintaining the cold chain cool the wireless connectivity is important for monitoring the temperature of the vaccine refrigerator. Connecting the remote appliances with mobile network/web network requires reliable wireless communication technology. Since this is closely related with lowe power and open source energy consumption considering IoT technology is good option for minimal use of energy.

Wireless monitoring could be done using combination of techinologies like WiFi, Bluetooth,Zigbee, 6LoWPAN and 4G-LTE network. New ZigBee Pro devices are very low power consuming devices and con be integrated with all kind of electrical appliances.[8] All these technologies use there respective standard IEEE protocols and are available with free or paid user licenses for wireless access. For example 2.5Ghz is a free user licence spectrum and 4G-LTE is not a free to use licence and owned by the companies which provide you with there mobile network.

Thermoelectric Coca cola refrigerator[edit | edit source]

This refrigerator runs on 12V DC/AC 110-volt.

It has 4 liter capacity and cools up to 32 degree F below ambient temperature(Around 5oC).

It costs $65.

Thermoelectric cooling technology allows the cooler to operate silently.

Thermoelectric refrigerator driven by solar cells[edit | edit source]

In this experiment the refrigerator was treated in ways during daytime and nighttime. Solar cells were used during the day and battery stored power was used during night and cloudy or rainy day with the help; and the battery was assisted by a.c. rectifier. Using this technique for thermoelectric refrigerator the temperature could be maintained between 5-10oC.

The cooling output of refrigerator and the solar radiation reach maximum levels at the same season and time, so its a good option to use solar power for refrigeration. The thermoelectric refrigerators are usually light, reliable, noiseless, rugged, low cost in mass production and uses electrons rather than refrigerant as a heat carrier. The thermoelectric refrigerator discussed here was filed for patent in china.[9]

During the day the refrigerator was driven directly by solar cells and in the night it was driven by battery. The auto switching between day and night configuration was done by the controller. The data logger was used to perform temperature monitoring during the test. The system was designed and analysed assuming that the hot side temperature of the thermoelectric module was 13 °C higher than that of the ambient temperature, and the heat conduction from outside to the internal refrigerator was neglected. Experiment shows that the cold side temperature of the module decreases quickly in the first 20 min, and stays steadily below 5°C after one and half an hours.

The refrigerator can maintain the temperature in refrigerated space at 5~10 °C, and has a COP about 0.3. The power output of the solar cells presented in this paper are really impractical and low. Today's solar cells give more power than the solar cells used in this experiment.

How does thermoelectric refrigeration work?[edit | edit source]

In 1834 Jean Peltier observed that when an electrical current is applied across the junction of two dissimilar metals, heat is removed from one of the metals and transferred to the other. Thermoelectric refrigeration is based on this fact and uses metals cubes to transfer the heat. Solid-state thermoelectric modules are capable of transferring large quantities of heat when connected to a heat absorbing device on one side and a heat dissipating device on the other. The heat dissipating device uses a small fan to disperse the heat into the air. These cooling systems are compact, light weight, lower priced and requires low battery as it is simpler than other refrigeration techniques hence require smaller cooling system construction. Periodic servicing and maintenance is required for effective thermoelectric cooling such as dusting and vacuuming. The modules do not deteriorate with useand can run with 12V battery and motor which can be replaced easily.

Enhancement of an Electronic Solar Tracking System[edit | edit source]

LDRs, photo transistors and IR sensors were used to test the performance of tracking system with these sensors. With different testing voltages, different irradiance and different alignment distances between sensors the photo transistors were found to be giving best output which made the tracking system better than with LDRs or IR sensors as solar irradiance sensors.

Infrared Photo Transistor[edit | edit source]

Infrared Photo Transistor could be better option than using LDRs as it can provide accurate and and more output voltage/power for sensing the sun light.

ABSOLUTE MAXIMUM RATINGS (25 Degrees C)

| Collector to Emitter Sustaining Voltage (Vce) | 30 V |

| Emitter to Collector Breakdown Voltage | 5 V |

| Collector Current | 25 mA |

| Operating Temperature Range | |

| Storage Temperature Range | 5 V |

| Emitter to Collector Breakdown Voltage | |

| Lead Soldering Temperature (1/16 inch from case for 5 sec) | 240 Degrees C |

| Relative Humidity at 85 Degrees C | 85% |

| Power Dissipation at or below 25 Degrees C Free Air Temperature | 100 mW |

ELECTRICAL CHARACTERISTICS

| Dark Current (Vce = 15 V) | 100 nA |

| Light Current (Vce = 5 V, H = 20 mW/cm) | 20 nA |

| Collector to Emitter Saturation Voltage | 0.4 V |

| Rise Time (10 to 90%) | 5 microS |

| Fall Time (90 to 10%) | 5 microS |

Microprocessor-Controlled New Class of Optimal Battery Chargers for Photovoltaic Applications[edit | edit source]

Performance Characteristics

| Method | Circuit Hardware | Software Simulation | Algorithm | Cost | Efficiency |

|---|---|---|---|---|---|

| VMPPT, Continuously adjusting charging current | Complex, 1524 IC, 8085 and lot of other components | Simulink, DC/DC buck converter, Battery Parameter calculation | Non-linear battery model, control Open circuit voltage & varying current using PWM signal | $15 - $20 | Shorter charge time, 40% to 75% faster charge time, Low efficiency |

FPGA Implementation of MPPT Using Variable Step-Size P&O Algorithm for PV Applications[edit | edit source]

Performance Characteristics

| Method | Circuit Hardware | Software Simulation | Algorithm | Cost | Efficiency |

|---|---|---|---|---|---|

| Perturbation and Observation method, Using FPGA XC2C384 Chip. | No integrated temperature sensor, But no need of current and voltage sensor. | Complex circuit Architecture on FPGA. | Non-linear model of PV panel power output, Variable step size P & O algorithm. | RioRand FPGA costs $25-$30, FPGA chip $40 - $50. | 96% efficiency |

A Fast and Accurate Maximum Power Point Tracker for PV Systems[edit | edit source]

Performance Characteristics

| Method | Circuit Hardware | Software Simulation | Algorithm | Cost | Efficiency |

|---|---|---|---|---|---|

| Open circuit voltage & short circuit current monitoring. | Buck-Boost Charge unit MPPT; VOC, IMP & ISC monitored & sent to MPPT Eqns(RHS) to control MPPT. | Simulink, Faster than other MPPT like P&Q & more accurate than approximate methods that use linearity between voltage (current) at maximum power point and open-circuit voltage(short-circuit current). | Non-linear V-I characteristics of PV panel are used in developing the algorithm and adjusting the MPPT according to the OCV and SC current. | Circuit construction is simple. So this is low cost application. | It is fast, good in different insolation, temperature and level of degradation; and Max deviation in max power is less than 1.5%. |

Accurate, Compact, and Power-Efficient Li-Ion Battery Charger Circuit[edit | edit source]

Performance Characteristics

| Method | Circuit Hardware | Software Simulation | Algorithm | Cost | Efficiency |

|---|---|---|---|---|---|

| Two high gain voltage and current feedback loops. | High efficiency circuit is good for optimal charging but not fit for MPPT tracking. | Not specified. | Uses a diode to smoothly{i.e., continuously) transition between two high-gain linear feedback loops and control a single power MOS device, automatically

charging the battery with constant current and then constant voltage. |

Small circuit and low cost. | 1.7 Hr charge time. 83% power efficient. Due to fast response it is accurate and efficient. Constant current output. |

A dynamic lithium-ion battery model considering the effects of temperature and capacity fading[edit | edit source]

While doing research on battery operated systems the system models are studied using simulation before putting together the functional hardware for the successful operation of system under consideration. For the successful simulation results battery model has to be giving similar results as the real battery under consideration. Lithium-ion batteries have effect of temperature and capacity fading on there performance over the life cycle. Generally a battery is considered to be usable until 80% of its capacity. The fading effect doesn't depend on whether the battery is in operation or not. Even if it is not in use it still fades. Calender life and cycle life loss of the battery increase linearly with time and increasing temperature.

The simulation model presented in this paper using Matlab/Simulink gives similar results to the real test performed with lithium-ion batteries at 25oC and 50oC as per the feedback of all the authors who did practical research on the lithium ion batteries. According to the results the charging and discharging characteristics are the same as shown by the simulation. The simulation modeling and design methodology has a modular structure that can be implemented, simulated and analyzed with different power and parameters of any desired lithium-ion battery system. The developed model has a proven result to be able to evaluate the battery performance under several different operating conditions. Because of proposed model's similar performance results, it can be directly used in different simulation models including battery systems.