Food drying with superheated steam

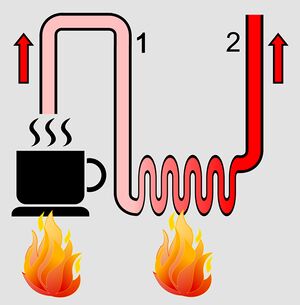

Super-heated or dry steam has the ability to drive moisture out of solid materials much faster and more cost-effectively than air drying while being gentler on the end product. This technology is getting a lot of interest in the food industry and could become the drying and frying technology of choice. It is far more cost effective than freeze drying. This technology has the potential to improve rural incomes by capturing the added value from food processing on the farm.

It also has advantages in terms of nutrient preservation. There is no free oxygen in superheated steam, so the decomposition of easily oxidized nutrients such as vitamin C is greatly reduced. This is a key advantage over food drying with hot air, which exposes the food to oxygen. (Aside: most people think that it's the heat that destroys nutrients in food, while it's actually the oxygen. This has been demonstrated with canned food, which often has very good nutrient preservation). Another advantage is that this process is much faster than traditional (solar) food drying, which is crucial when large volumes of one particular crop need to be processed at harvest time (think: tomatoes, strawberries, raspberries - these are all high value products when dry, and are easily transported, easily traded). By applying lower than normal pressure, it is possible to use temperatures far lower than 100°C (212°F), and as low as 45°C (113°F) for heat-sensitive foods.

Sources of energy (heat) are solar (weather permitting) and biomass, possibly in combination (day/night) for more reliability. When the heat source is pyrolysis (with biochar as a by-product) rather than combustion, the process can be made truly carbon negative, i.e. it actually pulls carbon out of the atmosphere every time you use it.

Examples: Food[edit | edit source]

- sugar: sugar beet pulp, dietary fibre from sugar beet

- spent distillers grain, brewers grains

- base materials: hog fuel, corn fibres, protein containing base materials (soy beans, rape seed, sunflower seed, soy meal, okara, etc.)

- shrimp, pork, bamboo shoot, paddy/rice, herbs, cacao beans, corn gluten, tobacco (drying, expansion)

- starch: starch, wheat flour, distillers grain

- meat (pork), bone meal, fish meal,

- vegetables & fruit

- dairy industry: milk powder, flash drying, yogurt dehydration

- potato products, fries (pre-drying), potato waste,

- grains (e.g. wheat - replaces traditional gas-fired grain dryer)

- other: coffee grounds, spices, linseed, sunflower seed, duckweed

Examples - other (non-food)[edit | edit source]

- biofuel: drying and grinding of sugary biomass for pre-processing before fermentation

- biomass: straw, sawdust, wood fiber, wood chips, wood pulp, spruce and birch bark, milled peat, peat for briquettes

- chemical industry: washing powder, pigment, potassium salt, powdery chemicals, catalysts, coloring agents

- laundry, dry cleaning

- wood, lime mud (before calcination), mineral wool, fibres, cement curing,

- sewage sludge, manure, grass

- textile applications (coated) textile, drying

- chemical processing - reaction kinetics manipulation

- paper, pulp, sludge, other cellulose derivatives,

- building materials

Links[edit | edit source]

- Publication: "SUPERHEATED STEAM: ITS NOT JUST ABOUT DRYING"

- Publication: : "Dehydration dynamics of potatoes in superheated steam and hot air"