Forest Andresen[edit | edit source]

I am Forest Andresen, a freshmen from western Massachusetts. I am a business and sustainability major but I enjoy engineering.

3D Printing[edit | edit source]

I am in the 3D printing class at Principia.

Open Source[edit | edit source]

Open source is the pay of the future. Away with all you over-protective knowledge hoarders! You are the reason that miss information is currently running rampant in the US. For the future we need new ways of spreading technical knowledge and advancements in technology, we need a faster and more efficient way of doing things. Open source labs, software, and design are the key to unlocking the a better, smarter, and more sustainable future. With open source technology, advancement comes more quickly and isn't locked up with patents and secrets. By leaving technology open source, we are unlocking the combined mind power of the whole world to make what exists better. Join me in welcoming the future.

More[edit | edit source]

| Picture | Description | Something else |

|---|---|---|

|

I stole this photo of of Kent's page and I don't know if he took it or not | Blank |

Videos[edit | edit source]

I will totally ad some timelapse of prints in progress!

Replacement part[edit | edit source]

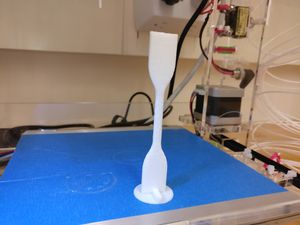

This was my second replacement part, the first one i printed was the c clamp and i lost it somewhere because I took it with me the whole day to show to everyone because I was proud. let me know if you find it. this piece is the knob for tightening the c clamp and it was a short print so I chose it. I went at 125% speed which seemed to work ok.

Strength test piece[edit | edit source]

This piece was actually really hard to print, because my printer is newly made and still has some trouble shooting to do. I could not figure out how to make it the right size and I think there were numerous problems with the slizing/gcode. Marie sent me a series of links to try to troubleshoot but I have literally been studying for financial accounting for the last three days.

Mini Mech Project[edit | edit source]

Analysis of the testing and results:

Testing these pieces was very interesting. I enjoyed the opportunity to work with tools built just for testing strength. In the end, some of my prediction were right, some are hard to comment on. The pieces printed in a horizontal orientation were, in fact, much stronger as I had predicted, but the speed of the print dimply didn’t seem to have any effect on strength, each piece had different results, but there is no indication that they are correlated to the print speed, as they do no change incrementally or consistently. The significant variation in strength was with the vertical coupon printed at 90 mm/s it had a strength decrease of 40 units, while most other tests, seem to randomly vary by give or take 5 units.

My conclusion is that I need to have a lot more pieces to get results that mean anything, the margin pf error in my case was very large, and probably accounted or the difference in all my data points.

My Predictions and First Step of the Scientific Process:

For the Mini Mech project I will make six Pasco style test coupons. Three printed in vertical orientation, and three printed in horizontal orientation. Each of the three coupons in both orientations will be printed at a different speed, 30 mm/s, 60 mm/s, and 90 mm/s. Using a testing device, the strength of all six pieces will be determined and recorded. I believe that there will be a difference in the strength of all of the pieces, not just due to the print speed but also due to the print orientation, in this case being vertical or horizontal. I also think there will be a difference in how each orientation responds to the different print speed. For instance, in the vertical orientation, an increase in print speed from 60 mm/s to 90 mm/s might reduce the strength by more than if two horizontal pieces were tested with the same difference in print speed. Overall, I think that the horizontal pieces will be stronger, and will not be effected by print speed as much as the vertical pieces. I believe that when the print speed is changed on the vertical pieces it will have a big impact on the strength (more than 10%), whereas when the print speed is changed on the horizontal pieces it will have minimal difference in strength (less than 5%. I think this will be the case because the printing of a vertical piece is much more complex than the printing of a horizontal piece, there is more stopping and starting and generally more movement of the z axis in a vertical piece. I think that because of the added complication of a vertical piece, the speed will affect the printers ability to do a quality print. Also, with significantly more layers in a vertical print, a slower print will allow them to adhere more effectively and make the print stronger.

My revised theory:

my theory still stands, but there is still no data to back it up. The only part of my theory that was proven to be correct was that the pieces that were printed horizontaly were stronger than those printed vertically. my revised theory states that we need significantly more tests to get data or results.

Projects[edit | edit source]

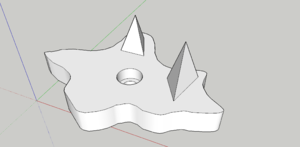

this is my rockwall hold

Science Project[edit | edit source]

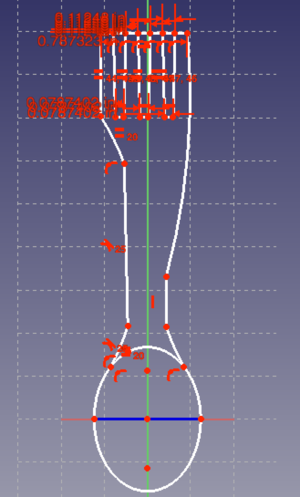

this is an image of the initial cad drawing for the battery cell holder for Ra X

OSAT Project[edit | edit source]