User:Dlbrinks/Ringbearer

Ringbearer: Movable LED ring for 3D print lighting and analysis[edit | edit source]

Background[edit | edit source]

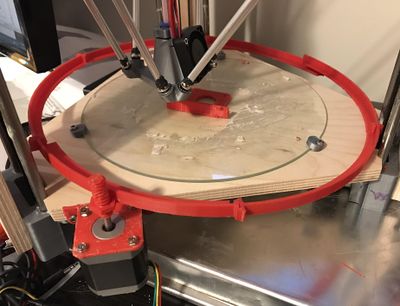

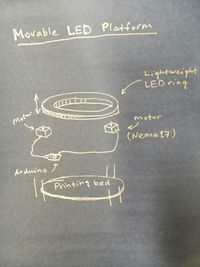

We would like to illuminate objects on our 3D printer bed, using an LED light ring, in a consistent and predictable way. This is specifically to enable the monitoring/examination of prints by a computer vision system, in real time. Due to the nature of computer vision analysis, best results are obtained in a well-lit, consistent environment, free of shadows. We would like to be able to change the height (Z) of this ring using stepper motors.

Objective[edit | edit source]

Design 3D printed apparatus to support a LED ring, and allow it to be moved up and down with stepper motors. Apparatus should minimize obstruction with normal operation of the printer.

Solution[edit | edit source]

Printed Components[edit | edit source]

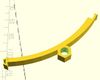

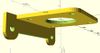

Ringbearer consists of several pieces which are individually printed and then assembled. It's difficult to print a 1-piece object this large, so Ringbearer is composed of several component pieces:

BOM / Non-Printed Components[edit | edit source]

These components are also needed in the Ringbearer design:

| Quantity | Name | Description | Unit cost |

|---|---|---|---|

| 2 | NEMA17 Stepped motors | These stepper motors attach to the elevator screw rods, and do the work for raising/lowering the LED ring | $13 |

| 8 | M3x ~5mm screws | Used to attach stepper motor to motor mount | $.01 (or scavenge from your local computer enthusiast) |

| 1 | Arduino | ...or other microcontroller capable of controlling the raising/lowering of LED ring as desired | $18.00 |

| 2 | Stepper motor driver | Used to easily drive stepper motor from microcontroller | $2.00 |

| Total | $48.08 |

Cost Analysis/Market comparison[edit | edit source]

No known existing product allows for the placement of a LED ring in the bed of a 3D printer, without interfering with printing operations, and allowing computer control of the LED ring height. With a total cost of $50 (potentially much less, for the scientist or hobbyist who has suitable microcontroller/stepper motors on hand), this is an affordable method for getting started in computer vision analysis of prints.

STL / OpenSCAD files[edit | edit source]

Please find the latest STL, Parametric OpenSCAD files, etc in the NIH Repository.

Demo[edit | edit source]

See the youtube video below for a quick demo of how this system goes together.