The processing and trade of spices has always been an important industry. The spice trade still has a significant impact on the economy of many countries eg Grenada, Sri Lanka and Indonesia. Small-scale processing of spices can be economically and socially successful.

Correct harvesting time[edit | edit source]

It is not possible to produce a good spice product from low quality harvested material. The main obstacle to correct harvesting is the crop being picked immature. This is usually due to fear of theft or the farmer requiring money urgently. However, every effort should be made to wait until the spices are fully mature.

Cleaning[edit | edit source]

The crop should be cleaned before processing. The first stage is to remove dust and dirt using a winnowing basket. This can be made locally from bamboo, palm or other leaves. Someone used to this work can remove the dust, dirt and stones quickly and efficiently (eg they could clean 100kg of pepper in an eight-hour day). Small machines are available for cleaning but they are rarely cost effective.

After winnowing the crop needs to be washed in water, all that is needed is two or three 15 litre buckets. For larger quantities a 1m³ sink/basin with a plug hole needs to be constructed. This can be made out of concrete. However, the water must be changed regularly to prevent recontamination of spices by dirty water. Only potable water should be used.

Drying[edit | edit source]

This is by far the most important stage in the process to ensure good quality spices. Inadequately dried produce will lead to mould growth. The sale value of mouldy spices can be less than 50% of the normal value. In addition the growth of food poisoning bacteria on some spices is a real danger if proper washing and drying is not carried out.

Drying during the dry season

During the dry season, sun drying is usually adequate to dry the produce. The simplest and cheapest method is to lay the produce on mats in the sun. However, there are problems associated with this method. Dust and dirt are blown onto the crop and unexpected rainstorms can re- wet the crop.

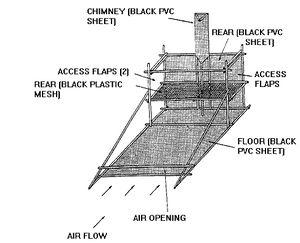

A solar dryer avoids these problems. The simplest type is the cabinet solar dryer, see Figure 1, which can be constructed out of locally available materials (eg bamboo, coir fibre or nylon weave).

For larger units (over 30kg/day) an 'Exell Solar Dryer' could be used, see Figure 2. However, the construction costs are greater and a full financial evaluation should therefore be made to ensure that a higher income from better quality spices can justify the additional expense.

Drying during the wet season

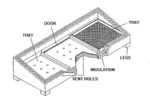

During the wet season or times of high humidity, which often coincides with the harvest of the spices, a solar dryer or sun drying cannot be used effectively. An artificial dryer that uses a cheap energy sourceis necessary. This may be a wood or husk burning dryer or a combined wood burning and solar dryer. Figures 3-6 show a combined wood burning and solar drier which is based on the McDowell Dryer and has been used in Sri Lanka.

The crop should not be overheated (eg the maximum air temperature for drying pepper and cardamom is 50ºC). Neither should it be overdried (the final moisture contents for various spices are shown in Table 1).

| Spice | Maximum final moisture content % (wet basis) |

| Mace | 6.0 |

| Nutmeg, cloves | 8.0 |

| Turmeric, coriander | 9.0 |

| Cinnamon | 11.0 |

| Pepper, pimento, chillies, ginger | 12.0 |

| Cardamon | 13.0 |

Table 1: Spice moisture content

The drying of certain spices requires special conditions. For example, cardamom has to be dried in the dark so that the green colour is retained.

Grading[edit | edit source]

Spices can be graded by size, density, colour, shape and flavour. Machines are available for larger scale production units.

Grinding[edit | edit source]

Grinding may also add value but must be done carefully as there are difficulties. A whole, intact product can be easily assessed for quality whereas a ground product is more difficult. There is a market resistance to ground spices due to fear of adulteration or the use of low quality spices. This can only be overcome by producing a consistently high quality product and gaining the confidence of customers.

For small-scale production (up to 100kg/day) manual grinders are adequate. Small Chinese or Indian models designed for domestic spice grinding are suitable. A treadle or bicycle could be attached to make the work easier.

For larger scale production a small, powered grinding mill is needed and models are available that can grind 25kg/hour. A grinding mill needs to be placed in a separate and well ventilated room because of the dust. Great care is needed to ensure uniform sized pieces/powders after grinding and also to prevent heating of spices during grinding.

- ---[1]

Sifter International manufactures Industrial ACM Spice Grinding Machinery. ACM grinder works in way that the characteristic flavor aroma and color of spices are same due to steam volatile essential or volatile oils and organic solvent soluble oleoresins, which is the strength of the spices. These volatile substances start evaporating at a temperature above 30°C. In ordinary Hammer Mill, Beater type Pulverizer is used in which temperature of the product goes up to 80°C, which affects quality of the spices. In addition to this additional cooling is required before packaging of the final products. Sifter International ACM Spice Grinding Machinery has got solution to this problem in our ACM series Micro Pulverizer (Cryogenic Grinding) and perfect technology for grinding of spices. ACM Spice Grinder will produce the exact desired finished size while preserving aroma and volatile oil qualities.

Outstanding Features of Industrial Spice Grinder:

1) Factory Direct, Low Prices.

2) Strict QC, High Quality Control.

3) Silent Running, Less Vibrations.

4) High Output and Uniform Particles.

5) Widely Used, Suitable For All Kinds of Hard and Brittle Materials.

6) All Contacting Parts Are Food Hygiene Standard Stainless Steel, No Corrosion Hazards.

7) Have Long-Term and Stable Raw Material Supplier, So Delivery in Time.

8) Low Specific Power Consumption, Leads To Faster Return On The Investments.

9) Low Temperature Rise for Heat Sensitive Materials.

10) Simple Structure, Easy To Install And Disassemble, Easy To Clean.

11) Simple And Convenient Operation, Can Control Particle Size By Replacing Sieves.

For more information please visit our website http://www.sifterinternational.com

Packaging[edit | edit source]

The packaging requirements depend on: 1) the type of spice, 2) whether it is ground or intact and 3) the humidity of storage. Most intact spices will store adequately in sacks/boxes if the humidity of the air is not too high. Ground spices can also be stored without special packaging if humidity is low but over long periods there is a loss of flavour and risk of contamination and spillage.

It is therefore better to store spices in a barrier film such as polypropylene (essential in areas of high humidity) to provide an attractive package, retain spice quality and prevent contamination and losses. If polypropylene is not available, cellulose film is adequate if it is heat sealable. Polythene is a poor substitute and should only be used for short term storage as it allows the flavour/aroma of the spices to escape.

Equipment suppliers[edit | edit source]

Note: This is a selective list of suppliers and does not imply endorsement by Practical Action.

Kaps Engineers 831, G.I.D.C. Makarpura

Vadodara - 390 010

India

Tel: +91 265 644692/ 640785/ 644407

Fax: +91 265 643178/ 642185

- Mills recommended for smaller equipment of lower throughput capacity or where frequent changeover of product is a criterion.

Power: Electric

Lehman Hardware and Appliances Inc. P.O. Box 41

Kidron

Ohio 44636

USA

Tel orders: +1 877 438 5346

Tel enquiries: +1 888 438 5346

E-mail: info@lehmans.com

Website: http://www.lehmans.com/

- Manual grain mill that adjusts from powder fine to flaky coarse.

Alvan Blanch Chelworth Malmesbury Wiltshire SN16 9SG UK

Tel: +44 (0) 666 577333

Fax: +44 (0) 666 577339

E-Mail: info@alvanblanch.co.uk

Website: http://www.alvanblanch.co.uk/

- Mills and Grinders General for fine or coarse grinding of crops.

Capacity: 15-1000 kg/hour. Hand powered and motorised

Premium Engineers PVT Ltd 603, Chinubhai Centre

Ashram Road

Ahmedabad - 380009

India

Tel: +91 (0) 79 657 9293/5987

Fax: +91 (0) 79 657 7197

- Mills / Grinders

A range of mills capable of grinding material to 100 - 250 mesh particle size. Food Groups: Herbs/spices/Cereals Capacity: 5-1000 kg/hour

Power: Diesel/Electric

Acufil Machines SF.120/2

Kalapatty

Coimbatore - 641 035

India

Tel: +91 (0)422 866108/866205

Fax: +91 (0)422 572640

Email: gondalu@yahoo.com

- Roasting equipment used for the roasting of dhal, spices, wheat and all food products that require pre-cooking or pre-roasting. Food Power by gas, battery, electric.

- Tray drier used for removing moisture from food products such as spices etc. Contains

12 trays. Capacity: 50 kg/chargePower: Electric

C S Bell Co

170 West Davis Street

PO Box 291

Tiffin Ohio USA

Tel: +1 419 448 0791

Fax: +1 419 448 1203

E-mail: sales@csbell.co.com sales@csbell.co.com

Website: http://www.csbellco.com/

- No.60 Power Grist Mill. This mill is suitable for use on large and small farms. Adjustable for grinding texture. Includes hopper, feed regulator slide, coarse and fine grinding burrs and 12 inch diameter pulley. Food Groups: Cereals/Oilseeds/Herbs/spices

Capacity: 150 kg/hour

Power: Electric/Manual

- La Milpa Power Mill

This machine will grind wet or dry material. It is adjustable for coarse to fine and has a feed auger with 12 inch V-pulleys.

Food Groups: Cereals/Herbs/spices/Oilseeds

Capacity: 150 kg/hour

Power: Electric

Acufil Machines SF.120/2

Kalapatty

Coimbatore - 641 035

India

Tel: +91 422 866108/866205

Fax: +91 422 572640

Email: gondalu@yahoo.com

- Roasting Equipment/ Automatic Roaster with

Electrical Heating Pad

Used for removing moisture or the roasting and heat impregnating processes. This system is totally covered and very hygienic. Food Groups: Cereals/Herbs/spices

Power: Electric/Battery

- Tray Drier

Used for removing moisture from food products such as spices etc. Contains

12 trays.

Food Groups: Herbs/spices/Vegetables

Capacity: 50 kg/charge

Power: Electric

Miracle Mills Ltd. Knightsdale Road Ipswich

IP1 4LE

United Kingdom

Tel: (01473) 742325

Fax: (01473) 462773

E-Mail: sales@miracle-mills.co.uk

Website: http://www.miracle-mills.co.uk/

Hammer mills & granulators

References and further reading[edit | edit source]

Cardamom (Practical Action Technical brief) Cinnamon Practical Action Technical brief Cloves Practical Action Technical Briefs Cunmin Practical Action Technical Brief

Nutmeg and Mace, Practical Action Technical Brief

Turmeric, Practical Action Technical brief

Processing of Black Pepper, ITDG Food Chain No. 3

Spice Plants, M. Borget, 1993, CTA/MacMillan

Ground and Packaged Spices: Options and Difficulties in Processing at Origin Marketing

Series 7, NRI, 1993

- ↑ Reference