Sand Battery Technology: A Promising Solution for Renewable Energy Storage[1][edit | edit source]

- Sand: abundant, inexpensive, available, Non-toxic

- sand-based electrodes--> store &release energy

- Use in small-scale residential systems to large-scale grid-level storage

- Adv:

- High energy density

- Long cycle life

- Cycle stability

- Safety

- Potential for renewable energy storage

- Sand-based electrodes--> potential in Li-ion & supercapacitors

- Sand-Based Energy Storage Technologies:

- Thermal energy storage.

- Mechanical energy storage.

- Electrochemical energy storage.

- Required materials:

- Sand

- storage medium

- should have high thermal conductivity

- low thermal mass

- withstand high temperatures

- Thermoelectric Generators

- Thermal energy in sand to electric energy (discharge: for electricity generation, power industry, space heating)

- selection: phase-change temperature & energy storage capacity.

- Electrodes/Heating Coil

- Transfer thermal energy between sand & the thermoelectric generator

- graphite or metal foils

- Insulation

- Reduce heat loss in charge & discharge

- Improves efficiency

- Heat Source:

- charge the battery & heat the sand

- Can be solar/ waste heat from industry/ renewable / nonrenewable thermal energy

- Container

- Holds everything

- withstand high temperatures & thermal stresses.

- Sand

- Design-->based on amount of required thermal energy & storage duration

- Energy generation & storage:

- wind / solar --> electricity

- 30%-->immediately power local infrastructure

- 70%-->store in sand battery & heat to 600-1000°C

- weaker solar--> use the stored energy

- Charge:

- Heat to sand--> increase temp --> until treshold-->full energy

- sand type & heat source--> different charge time

- Discharge:

- sand--> expose to a heat sink or device that extracts the heat

- sand temp drop-->energy release as heat

- Sand type & heat sink temp-->different discharge time

- Sand-battery type:

- Indirect Heat-Storing:

- heat transfer fluid (transfer heat to & from the sand)

- higher temp operation

- large physical footprint

- Direct Heat-Storing

- Direct contact with heat source & heat sink

- lower temperatures operation

- compact

- Thermochemical Heat-Storing

- chemical reaction

- store more energy

- longer charge & discharg time

- Hybrid Heat-Storing

- Combine of direct & indirect

- higher energy density

- faster charge & discharge

- Indirect Heat-Storing:

- Application

- Renewable Storage

- Heat & Cool

- Emergency Backup Power

- Challenges

- Efficiency --> depends on material/ design/ operating condition

- operating temp

- scale up

Sand Battery: An Innovative Solution for Renewable Energy Storage (A Review)[2][edit | edit source]

- UAE --> aims to use 7% of its energy from renewable sources (specifically solar)--> but challenging -->UAE deserts sand

- Sand composotion: silicon dioxide

- Subzero temp areas -->sand-bed-based solar heat/thermal storing promissing

- Dry sand-based TE--> High temp and high energy --> can be used in infrustructure of facilities like car parks

- Obtainable Materials: sand and rocks

- Installedcyclical storage structures: Germany, Canada, Turkey, Korea, the Netherlands, the United States, Finland, France, and Switzerland

- Sand: store up to 1000 °C, zero mass loss, reduced ownership and maintenance costs, improved and stable energy exchange rates

- sand medium: in a single basin solar--> increases the yearly mean of daily output by 23.8% (compared to no sand), hold the thermal energy for extended time, can be used during winter (when no solar available)

- Principle:

- 30% of the renewable used, 70% stored in sand --> increase temp to 600-1000

- Component of battery:

- steel casing--> sand & heat transmission piping

- External--> mechanical mechanisms, regulators, heat exchangers, fan

- Operation:

- Charge

- Storage

- Discharge

- Mechanism:

- Circulating hot air around sand --> Renewables control a resistance electric heater to increase the temp of the air near sand

- heat exchange tubing by a fan

- Dense insulation --> cover --> maintain temp

- Discharge: blow cool air--> heats up --> can steam water

- A COMPARISON OF DIFFERENT TES SYSTEMS TABLE AVAILABLE

- Disadv:

- Limited Temperature Range (300-1000)

- Slow Charge

- Low Power Density

- Land Use

- Transportation

- Recent:

- optimize particle size & distribution

- Application

- grid-level storage

- portable devices

- off-grid power systems

- industrial heating

- building heating

- district heating

- agriculture

- mining systems

Uses of sands in solar thermal technologies[3][edit | edit source]

- rock or mineral particles-->silica (quartz), feldspar, carbonates, micas, amphiboles, pyroxenes--> 0.06 to 2 mm in diameter

- 6% of land surface area (6% of the Earth land surface area in different regions)

- 2% North America

- over 30% Australia

- more than 45% Central Asia

- $11 and $58 per metric ton

- specific heat capacities: between 700 and 1000 J/kg◦C

- Thermal conductivity depends on porosity, granularity, moisture content, & mineralogy

- less porous-->higher thermal conductivity

- Smaller particles--> less thermal conductivity

- saturated with water --> higher thermal conductivities

- Quartz thermal conductivity: 7.7 W/m.K

- other sand constituents thermal conductivities: from 2.5 to 3.6 W/m.K

- non-toxic, non-corrosive, and non-flammable

- Sand in solar

- Thermal Energy Storage

- Solar Absorption

- Heat Transfer

- heat insulationsuitable

- large surface area --> water evaporation as evaporative medium

- Solar Distillation

- solar radiation --> obtain fresh water from impure water

- Limitation: low yield during the day and none at night

- with sand

- fill the area beneath the basin liner, the basin itself /using containers like metallic boxes, cotton bags, or mud pots

- maintain higher temperatures

- increase the evaporative surface area through capillary action

- fine, uniform sand better, black better, min thickness better, no water height above

- Solar heating

- Solar thermal collectors + thermal energy storage media

- High quartz content, low porosity, & high moisture content

- Dry sand with low quartz content

- Tank thermal energy storage

- Water: high specific heat capacity but Heat Loss --> Surrounding tanks with sands of low thermal conductivity; Sandy soil: lower heat capacity & thermal conductivity--> less heat loss from tanks compared to granite soil

- Require

- Low specific heat capacity and thermal conductivity

- Dry

- sufficient depth

- Aquifer Thermal Energy Storage (ATES)

- contain porous and permeable sand layers

- hot water in summer--> inject to the aquifer-->heat the soil and existed water--> extract the heat in winter, e.g. 72% recovery in Gassum Formation in Denmark

- Require

- High heat capacity and thermal conductivity

- High porosity and permeability

- Borehole Thermal Energy Storage (BTES)

- heat to ground by U-pipe heat exchangers in summer-->extract in winter

- high quartz low porosity sand --> good over bentonite or gravel

- 50% more heat for a 50% longer duration compared to gravel --> 78% efficiency

- Belgium: yearly storage efficiency 70%

- Require

- high thermal conductivity and heat storage capacity

- Packed-Bed Thermal Energy Storage

- use packed-bed sand in insulated pits

- 64% to 91% savings

- 65–75% of domestic hot water needs

- Finland

- Sand --> filled in containers or pits, heat transfer fluid flow through the bed--> Heat transfer in low demand (summer) & extract in high demand

- Require

- high thermal conductivity and specific heat capacity

- Solar Greenhouse Enhancement

- thermal storage walls (Trombe walls) --> increase air and soil temperatures in greenhouses

- made of: blackened surface (absorbs solar radiation, transferring heat to the sand), sand, and insulation

- greenhouses with sand thermal storage walls

- daytime air temp--> rise by 6.4°C above ambient, nighttime temp--> rise by 1.1°C

- Soil temp-->depth of up to 8 cm--> rise by 6.4°C during the day and by 4°C at night

- earlier flowering (by 14 days), earlier maturities (by 20 days), and higher yields (by 33.4%)

- Solar Dryers

- solar radiation --> dry agricultural or food products

- quartz, sand, gravel, soil minerals, sandstone, rocks, limestone, granite stone, soil, clay, waste concrete, fire bricks, and water

- sand:

- in drying chamber and the solar air heater--> reduce drying time & prevent the re-absorption of moisture at night

- increase the absorber surface area & roughness

- black-painted fine sand & high specific heat capacity & thermal conductivity

- Solar cooking

- Concentrating Solar Power (CSP)

- run a power block

- Which sand?

- Impurities in quartz (should be below 2%) --> less energy density

- Clays, carbonates, and feldspars--> agglomeration, degradation / reduced specific heat capacity

- Clays --> higher agglomeration at 600°C

- Carbonates --> decarbonization below 800°C--> mass loss & altered grain-size distribution

- Feldspars --> vitrify below 1200°C-->agglomeration --> impact on sand movement.

- Moderate cooling rates ~ 573°C required

- Below 1200°C --> quartz to cristobalite --> grain crack

- Solar gasification

- gasification: carbonaceous materials (like cokes, coal, biomass) --> fuels or chemicals

- Conventional methods: burning some of these raw materials --> heat generation for gasification --> loss of material & CO2 emission

- solar--> heat the material (no need to burn materials)----> quarts: receive, transfer & store heat & is inert (no reaction with materials) --> higher fuel quality & less carbon emission

- mix the carbonaceous materials with quartz --> solar is absorbs and transfers heat by sand --> raise temp (1100) --> thermal decomposition of carbonaceous materials --> syngas (synthetic gas) production

- require:

- High specific heat capacity and thermal conductivity

- Adiabatic Compressed Air Energy Storage

- Conventional: Excess electricity compresses air --> stored in underground--> natural gas required for reheat when required

- in sand: heat generated during compression --> store --> reheat compressed air when required by sand

- Charge: Hot air--> through heat exchanger --> sand flow in apposite direction --> sand warm, compressed air cold

- Discharge: cold compressed air--> through heat exchanger --> hot sand raise air temp

- electric cycle efficiency 69%

- High thermal conductivity and specific heat capacity

- Solar Photovoltaic/Thermal Panels

- PV-->small fraction of radiation to electricity --> excess to heat --> damage

- can be store in sand --> Cools down Pannels & prevent overheat

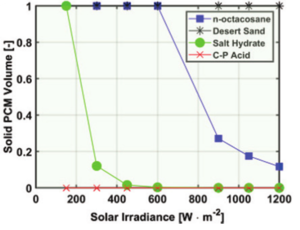

- e.g: desert sand and phase change materials (e.g., n-octacosane) --> Desert sand better heat transfer

- most suitable: high thermal conductivity and specific heat capacity

- Solar ponds:

- application:

- Industrial Process Heat

- Desalination

- Space Heating

- Power Generation

- Greenhouse Heating

- Salt Production

- Upper zone: low-salinity water--> insulator

- middle zone (Non-Convective Zone or Halocline) --> gradient of increasing salinity as depth increases --> density gradient--> convection currents prevention from forming -->traps heat in the lower layer

- Lower zone: high-salinity water-->Stores solar heat--> temp up to 85°C (185°F) or higher

- encasing sand in bottom and aournd lower layer --> reduce heat losses ( 69%) & store TE

- high thermal conductivity and specific heat capacity sand

- application:

- Solar-Powered Refrigerators:

- two metal cylinders --> sand-filled space between saturated with water

- solar --> power evaporation for cooling --> effective, accessible, sustainable

- Recommendation for research gaps:

- Coatings for Quartz Sand--> improve absorption, high mechanical wear & high temperatures up to 1000°C

Relationship between the PCM solid fraction and the solar irradiance[4]

Comparative CFD analysis of thermal energy storage materials in photovoltaic/thermal panels[5][edit | edit source]

- Desert sand (abundant, resistant to agglomeration, withstand high temperature) & silicon carbide --> enhanced heat transfer

- This study: copper pipe containing a water stream in a rectangular phase change material (PCM) exposed to solar, Additional absorber Layer

- under varying solar irradiance levels (ranging from 150 to 1,200 W/m2)

- desert sand: temperature of the liquid at the outlet boundary and the maximum temperature of the TES matrix are closer --> better heat transfer

- Relationship between the PCM solid fraction and the solar irradiance:

- Desert sand retains heat -->4,500 seconds after heat flux switched off

- n-octacosane retains for longer periods-->store and release heat over an extended period--> better for when heat release overnight required

Cost-effective Electro-Thermal Energy Storage to balance small scale renewable energy systems[6][edit | edit source]

- Assumes 100% conversion of electricity to heat

- quantity of electricity (P) needed to charge the energy storage: P=mCpΔT/t

- m: mass of the thermal storage material

- Cp: average specific heat capacity

- ΔT: temperature difference during charging

- t: time taken

- Thermal to electric = ηth*efficiency (efficiency in sand~85%)

- Heat rate = Power output /Thermal to electric efficiency

- Time for temperature decrease = Energy stored/ Heat rate

| Materials (1.5 mᶟ) | Tmin (◦C) | Tmax (◦C) | Charging (kWh) | Discharging (kWh) | Efficiency |

|---|---|---|---|---|---|

| Thermal Oil | 180 | 410 | 192 | 84 | 44% |

| Molten Salt | 200 | 500 | 372 | 118 | 32% |

| Sand | 180 | 950 | 424 | 360 | 85% |

| System/material selection | Quantity of storage material(kg) | Unit price | Total capacity | Base load capacity | Price in ($) | Systemcomponents cost $ | Total

designcost $ |

Storage cost $/kWh |

|---|---|---|---|---|---|---|---|---|

| ETES/Sand | 2446 kg | 0.25 $/kg | 359 kWh | 88 kWh | 672 | 24142 | 24814 | 69 |

Performance evaluation of a sand energy storage unit using response surface methodology[7][edit | edit source]

- Annual energy consumption: ~624,430 TWh

- Carbon footprint from fossil fuels: 36.7 billion ton

- Renewable energy demand in 2019: 6890.7 TWh

- Expected increase by 2,493 TWh between 2022 and 2025

- Types of TES Systems:

- Sensible Heat Storage: Simple and cost-effective.

- Latent Heat Storage: phase change materials.

- Thermoelectrical Storage: conversion between thermal and electrical energy

- Storage media:

- rocks, water, oil, salt

- Salt: Must be below 600°C

- Concrete Bricks: daytime, under 500°C, Temperature changes during discharge--> cycle effectiveness reduction

- SAND:

- High Thermal Capacity

- High Thermal Conductivity

- cost-effective

- Long-Term Stability

- Non-Toxic and Environmentally Friendly

- High-Temperature

- Optimum size for heat transfer 2–3 mm (larger: heat transfer effectiveness reduction, smaller: Increase in pressure drop-->larger heat exchanger volume)

- This Research:

- helical coil made of copper inserted inside a cylindrical tank

- Hot inlet fluid --> into the coil at temperatures up to 200°C

- Thermal Conductivity Measurement: KD2 Pro Decagon device with a TR1 single needle sensor type at 25°C

- Specific Heat Capacity Measurement: DSC-25, temperature range 25–200°C

- Specific Gravity Measurement: 1 kg of desert and beach sand, dried to constant mass (at 110 ± 5 ◦C) then add 6% moisture--> dry for 15-19 h.

- Experimental results:

- XRF

- Desert sand:13 elements, calcium 60.96%.

- Beach sand: 11 elements, calcium 86.9%.

- specific heat capacity

- increase with temperature

- Cp for desert-->higher

- dehydration of calcium hydroxide formed after heat treatment at 200°C

- Density

- Beach sand: denser

- scenario for simulation:

- Hot oil--> at 100°C & 0.01 m/s velocity--> heat transfer to 25°C sand, oil temperature decrease--> sand temperature and stored energy increase

- oil temp change --> increase sand temp and stored thermal energy

- oil velocity and coil turns increase--> stored energy increase

- total stored energy per kg of sand-->6.348 kJ/kg after an 8h charging .

- pressure drop -->71.4 Pa

- desert sand Thermal conductivity -->higher than beach sand by 1.77%

- Thermal resistivity of beach sand -->29.3% higher compared to desert sand

- XRF

Improved effective thermal conductivity of sand bed in thermal energy storage systems[8][edit | edit source]

- Introduction:

- TES--> substitute for lithium-ion batteries in stationary electric-grid storage

- Sand--> high thermal tolerance (melting point around 1700°C)

- wide temp range-->Enhanced Carnot cycle efficiencies

- sand High specific heat capacity --> high energy density BUT granular form & point contact between grains -->low thermal conductivity

- Coating of quartz sand --> improve solar absorption & thermal stability & enhancing energy storage efficiency by 60% to 80% compared to raw sand

- thermal conductivity of bentonite sand--> increase by add granite powder

- common methods-->Direct solar heating and heating by fluidisation (Circulating heat transfer fluids through heat exchangers in sand-packed beds)

- Mixing different heat storage materials--> improve storage properties

- Waste material streams-->economical materials option

- cut metal scrap from Metal workshops --> circular economy

- This research:

- Rectangular aluminium container (height 380 mm, length 230 mm, width 380 mm) --> investigate thermal properties of sand bed

- Two tubular-type resistance heaters (height 298 mm, width 309 mm, diameter 50 mm)--> 95 mm apart in the center of the box--> 2 kW On/Off control box & temp regulation up to 1000 °C

- K-type thermocouples --> between heaters (45 ±0.7 mm from each heater) and 30 mm away from heaters

- Sand bed -->exposed to air (T below 26 °C) without insulation

- Combination of sand and metallic by-products (enhance thermal conductivity)

- Brown Silica: silica (SiO2), grain size 0.06 to 0.2 mm, melting point 1713 °C, specific heat capacity 703 J/(kg⋅K), thermal conductivity 0.2 to 0.7 W/(m⋅K), bulk density 1800 kg/m3

- aluminium:15 to 20 mm long, 0.5 mm thick, 1.5 mm wide, melting point 660 °C, specific heat 897 J/(kg⋅K), thermal conductivity 205 W/(m⋅K), density 2712 kg/m3

- brass:diameter 0.25 mm, length 4.5 mm, melting temperatures 900 to 940 °C, specific heat 380 J/(kg⋅K), thermal conductivity 113 W/(m⋅K), density 8430 to 8730 kg/m3

- mixed metal chips: 90% steel, 10% aluminium/ length 10-15 mm, thickness 0.5 mm, breadth 1.5 mm/ Tm: 1370-1540 °C/ specific heat 490 J/(kg⋅K)/ thermal conductivity 50-70 W/(m⋅K) (varies by alloy)/ density: 7850 kg/m³

- T4: between wall and electric heater/ T3: between two electric heaters

- surface temperature reaches 500 °C within 30 min

- T4: heat faster than T3 in first 75 min (17.5 mm closer to heat source) & temperature constant at 350 °C after 3 h & rapid temperature decline outside heating elements

- T3: hotter than T4 after 80 min, equals surface temperature of heaters after 7 h & less rapid heat loss to environment & heat trap/ low thermal conductivity, high heat capacity of sand --> Terminal lag in T3

- Sand conductivity: 0.114 W/(m⋅K)

- Simulated charging time: five hours

- Brass-sand layer: highest effective thermal conductivity/ higher density and less porous structure--> lower thermal conductivity than aluminium

- Aluminium chips:

- More effective in uniform mixture: high thermal conductivity

- 20% aluminium: heat rate 1.7 times of pure sand & increases stable T4 temperature --> higher effective thermal conductivity

- 10% and 5% aluminium heat rates 1.36 times and 1.18 times of pure sand

- Higher aluminium:increased percolation & more interconnections --> facilitate heat transfer

- Lower chip concentrations: isolation of chips, fewer conductive paths, & lower thermal conductivity

- enhances overall temperature gradient of sand bed

- mix-metal chips--> lower performance: higher steel content (lower thermal conductivity)

- temperature outside thermocouples: metal composite--> Higher temperature than pure sand

- Metallic chips: easy heat travel--> more storage

- Commercial scrap metal prices in Finland--> Aluminium: 0.7 & Brass: 3.1 & Stainless steel: 0.7

From waste to value: Utilising waste foundry sand in thermal energy storage as a matrix material in composites[9][edit | edit source]

- Introduction:

- Waste foundry sand (WFS) by-product of metal casting processes

- WFS characteristics: ceramic composition, density, particle size (0.15 mm < D < 0.6 mm), specific surface area

- WFS recycling pathway: key material for composite phase change materials to capture, store, reuse waste heat

- This research:

- Materials:

- NaNO3, natural materials including clay, fully recyclable, Bentonite in sodium form, waste foundry sand (CPCM matrix material, predominant component: SiO2 at 87.91%, secondary components: Al2O3 at 4.7%, Fe2O3 at 0.94%), Additive X (?)

- Fabrication:

- Comminution with mortar and pestle (85–95% between 0.6 mm and 0.15 mm uniform grain size distribution)

- Hand-stirring mixture

- Shaping into 13 mm pellets under 60 MPa pressure for 2 min

- Sintering at 400 °C, 5 °C/min in high-temp

- Cooling to room tempe for shape-stable structure

- Poor cohesion at 70–30 (WFS-salt) mass ratio -->instability

- Additive X (?):

- Thixotropic properties form gel-like matrix with water--> improving WFS particle binding

- Increases CPCM resistance to stresses during phase change process

- Tests:

- Sand grain density: Helium-based pycnometer, 2.51 ± 0.06 g/cm³

- Bulk density: Mass and volume (dimensions) of individual pellets, Porosity deduced from density ratio

- Latent heat, melting point, specific heat capacity: DSC: Temperature range: 20 to 400 °C, ramping speed: 10 °C/min, Aluminum crucibles, ambient air environment, gas flow rate: 100 ml/min, sapphire method for specific heat

- Thermal conductivity and diffusivity: Laser Flash Technique, Level sample surfaces, graphite spray coatingAirflow setting: 100 ml/min, Thermal conductivity formula: λ = a(T)ρ(T)Cp(T)

- TGA: Sample weight: ~10 mg, platinum crucible, Temperature range: 25 to 500 °C, heating rate: 10 °C/min, ambient air

- Microstructure and pore size distribution: X-ray nano-CT, Cylindrical samples: φ 2 × 15 mm, Voltage: 95 kV, current: 150 μA, pixel resolution: 9.5 μm, Projection images at 0.1° intervals, 180° rotation, Data analysis: Recon software, CTan software

- Coefficient of thermal expansion: Optical dilatometer, Cylindrical samples: ~13 mm diameter, Heating: ambient temperature to 500 °C, rate: 5 K/min, air environment

- Compressive strength

- Thermal cycling protocol: Temperature increase to 400 °C, hold for 30 minutes, Temperature decrease to 270 °C, hold for 10 minutes,Total of 48 cycles, Structural resilience and thermal efficacy assessment of WFS-salt CPCMs

- ..... (discussion)

- Energy storage density: 628 ± 27 kJ/kg for Na60, 567 ± 43 kJ/kg for Na55

- Average thermal conductivity: 24% higher for Na60 (1.38 W/mK) than Na55 (1.08 W/mK), due to higher porosity of Na55

- Compressive strength: 141 MPa for Na60, 105 MPa for Na55, influenced by porosity and pore size

- Larger porosity beneficial for CTE of CPCM

- Materials:

Heat Storing Sand Battery[10][edit | edit source]

- Desert sand can store thermal energy up to 1000 ℃

- 400 ℃ higher than molten salt

- Molten salt:

- maintenance to avoid plugging

- External heat needed to maintain temp above 260 °C

- 28,000 tons --> for 7.5 hours of storage

- 25.2 million dollars for storage medium

- This research:

- Electric heater chosen as heat input

- Heat by heater -->to heat exchanger through Heat Transfer Fluid (oil)

- Oil -->in an oil tank, pumped through pipes to heat exchanger

- Temp sensors--> monitor sand temp change

- Charging: Sand heated to desired temperature (150 °C)

- Storing: sand thermal energy retention over time

- Discharging:

- Cold oil -->through pipes to absorb sand heat

- Thermoelectric generator--> thermal energy to electrical energy

What Is a ‘Sand Battery’?[11][edit | edit source]

- First commercial sand battery: In Kankaanpää, Western Finland (max temp:600 ℃, can be higher though)--> integrated into a district heating network operated by Vatajankoski (Green energy supplier)

- In residential and commercial buildings (homes & swimming pool)

- Structure:

- Insulated silo of steel housing filled with sand & heat transfer pipes.

- Automation components, valves, a fan, & heat exchanger or steam generator.

- Heating:

- Electricity from the grid or local production from wind and solar.

- Charged during periods of clean and cheap electricity availability.

- Electrical energy -->heat air with electrical resistors --> via a closed-loop air-pipe--> circulate it through heat transfer piping--> to heat storage

- Extraction:

- Blowing cool air through pipes--> heat up

- used to convert water into process steam / heat district heating water in an air-to-water heat exchanger.

- Stay hot for months, typically charged and discharged in 2-week cycles

- Best range of use when charged and discharged 20 to 200 times per year

- In "Polar night energy":

- 600 °C, 10GWh, 100MW

- 36% of industrial heating demand can be provided by sand battery (now is relying on oil and gas)

- can save 100 Mt/year carbon mono oxide in 2030

- can supply power for about 10,000 people

- 30% of solar/wind--> direct use, 70% stored as heat, less than 10% need for external energy for the whole year

Climate change: 'Sand battery' could solve green energy's big problem[12][edit | edit source]

- Finland long border with Russia and halted gas and electricity supplies due to Finland joining NATO -->Concerns over heat and light sources during long, cold winters

- World first fully working sand batteryinstalled by Finnish researchers-->developed by "Polar Night Energy"

- power plant in western Finland --> 100 tonnes of sand inside a grey silo

- Difficulty in efficiently converting stored heat back to electricity.

Sand Battery For Thermal Storage[13][edit | edit source]

- Batsand: Thermal battery with heating generator and sand vessel.

- bring hot and fresh sand directly to the home

- Charge (with solar panels) in summer--> heating / cooling when needed

- potential to return investment in 4-6 years

- combine with solar panel --> Can disconnect from grid

- Rated Power: 1:14 KW, 2: 25KW

- Battery Capacity: 1: 12000 KWH, 2: 21000 KWH

- Suitable Home Size: 1: 300-600 m², 2: 500-1200

- Size: 1: 140 cm x 72 cm x 55 cm, 2: 185 cm x 85 cm x 72 cm

- Weight: 1: 142 Kgs, 2: 174 Kgs

How a Sand Battery Could Revolutionize Home Energy Storage[14][edit | edit source]

- University of Michgan: 30% of total US residential enery use--> dedicated to heating (water heating:13%)

- US Lawrance Berkeley National Laboratory: 1/5 of energy produced in US--> building thermal load

- DraKE landing solar community-->2012: 96%, 2015, 2016: 100% of their yearly heating from solar

- TES: good round trip efficiency (RTE) rates (% of electricity into storage)--> 100% RTE: every stored energy can be used; thermodynamically impossible

- lead acid:70%, Li ion: 90%

- sand: low specific heat, high density: large storage of thermal, no chemical reactions: no maintanace, above boiling water

- heat sand with solar-->move to home with air

- challenge: size--> Batsand ($7700-increase to $19000 with installation, store energy at 92% efficiency with 94% RTE) is in small size (40m^3), under ground-->300-400 m^2 building, 10680 kW/h with +30 kW solar

- Newton Energy Solution (NES) ($5300-6400, 95% RTE)--> between TES & water heater & buffer tank--> water heater already a TES (but can't turn heat to electricity) water volume of 590 mm x 1650 mm (214 L)--> 20 kWh (can heat 600 L tap water to 40 °C &, 320 L--> 29 kWh

- the efficiency drop to 50-70% when heat to electricity

DIY Sand battery HEATER. Over 599f simple to make[15][edit | edit source]

- Equipment:

- 30 L steel tub

- water heating element--> 300W 12v

- hardware sore sand (play sand)--> 5-8 kg

- ventiliser is required

- watt meter

- Method:

- Fill half way

- put element in center

- connect the w meter to the element wire

- in 40 min--> 179°C, in 50 min--> 290 °C

Sand Energy Storage System for Water Heater[edit | edit source]

- Demand for new and effective storage materials.

- Use of sand, abundant in Jordan, as a storage material.

- Silica sand predominant in southern Jordan, comprising 95.5% to 98.31% SiO2

- Specific heat capacity of silica sand: average 830 J/kg°C

- Energy stored proportional to temperature rise, specific heat capacity, and mass of medium.

- Solar Radiation in Jordan:

- Yearly average: 2080 kWh/m2.

- More than 300 sunny days annually.

- Average daily radiation: 5.7 kWh/m2, with 8 hours of sun.

- June and July have highest sun hours (almost 12 hours) and radiation values (8.2 kWh/m2).

- December and January --> least sun activity ( 5 hours/day) and lowest daily radiation (2.9 kWh/m2).

- Optimizing inclination angle between 10° and 60° increases yearly radiation to 2419 kWh/m2.

- Most economical and effective inclination angle for PV system installation in Jordan: 30°.

- Yearly radiation at this angle: 2330 kWh/m2.

- Jordan Weather:

- Hottest month: July (average temperature 25°C/77°F).

- Coldest month: January (average temperature 8°C/46°F).

- Temperature fluctuation parameters: between 31°C and 4°C throughout the year.

- Rare cases of extreme temperatures: up to 43°C and as low as -10°C in different regions of Jordan.

- Energy storage design for night use as water heating source.

- Standard hot water temperature: 70°C.

- Average hot water use per person in Jordan: 40 liters/day.

- Average household size in Jordan: 5 people.

- Total water to heat: 200 liters (rounded to 240 liters).

- Water mass: 240 kg.

- Specific heat of water: 4.186 kJ/kg°C.

- Required temperature: 80°C (including error).

- Min temperature in January: 5°C.

- Temperature difference (∆T): 75°C.

- Energy required (Q):

- Q=m×Cp×ΔT=240kg×4.186kJ/kg°C×75°C=75,348kJ

- Least sun hours per day in December: 5 hours.

- Least average solar radiation per day in December: 2.9 kWh/m².

- Energy demand: 75,500 kJ --> 20.98 kWh.

- Silica sand

- Thermal conductivity: 0.33 W/m°C.

- Average thermal heat capacity: 0.83 kJ/kg°C

- ∆T: 75°C

- m=Q/Cp×ΔT-->m=1,213kg.

- Density of silica: 1,522 kg/m³ --> V= 1 m3

- System Design

- Storage tank

- Heat exchanger

- D= 60 cm & H= 0.9 m

- inlet top, outlet bottom

Solar Power Calculator for London, Ontario, Canada[16][edit | edit source]

- yearly avg of solar radiation in London Ontario: 1547.32 kWh/m2

- avg daily radiation: 4.232 kWh/m2

- Months of highest sunny days: June 9.6h & 6.08 kWh/m2, July 10.1h & 6.11 kWh/m2

- Least sun activity: Jan 2.3h & 1.97 kWh/m2, Dec 2.7h & 1.67 kWh/m2

Climate and monthly weather forecast, London, Canada[17][edit | edit source]

- Avg temp in hottest month: 25.5

- Avg temp in coldest month: -8.2

- ↑ Sand Battery Technology: A Promising Solution for Renewable Energy Storage

- ↑ Sand Battery: An Innovative Solution for Renewable Energy Storage (A Review)

- ↑ Uses of sands in solar thermal technologies

- ↑ http://dx.doi.org/10.1016/B978-0-12-818634-3.50133-8

- ↑ Comparative CFD analysis of thermal energy storage materials in photovoltaic/thermal panels

- ↑ Cost-effective Electro-Thermal Energy Storage to balance small scale renewable energy systems

- ↑ Performance evaluation of a sand energy storage unit using response surface methodology

- ↑ Improved effective thermal conductivity of sand bed in thermal energy storage systems

- ↑ From waste to value: Utilising waste foundry sand in thermal energy storage as a matrix material in composites

- ↑ Heat Storing Sand Battery

- ↑ https://polarnightenergy.fi/sand-battery

- ↑ https://www.bbc.com/news/science-environment-61996520

- ↑ https://www.batsand.com/

- ↑ https://www.youtube.com/watch?v=KVqHYNE2QwE&t=62s

- ↑ https://www.youtube.com/watch?v=4uUwMaiY12M

- ↑ https://solarcalculator.ca/report/Ontario/London/#:~:text=To%20navigate%2C%20press%20the%20arrow,panel%20slope%20of%2034o.

- ↑ https://www.weather-atlas.com/en/canada/london-climate