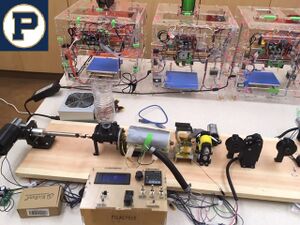

Principia Filament Extruder 2019

One of the biggest hurdles in developing nations is locating locally sources and affordable parts and expendables, including filament for use at tech labs in rural Africa. To solve this problem, Principia students created a preliminary design and developed a filament extruder that could use recycled plastic bottles (ubiquitous in the waste stream even in rural developing towns) to manufacture usable filament.

Project goal[edit | edit source]

The overall goal of the project was to create an affordable and effective filament extruder that could process recycled plastic bottles that could be used in third-world countries. This overall would promote sustainability while creating accessible manufacturing for those that need it. Another feature of this goal was improving the usage recycle waste PETG plastics that abound in every remote corner of the globe, by transforming it into usable 3D printing filament which can then be used locally to produce sustainable solutions to issues local communities in food production, health services, and other areas.

Design[edit | edit source]

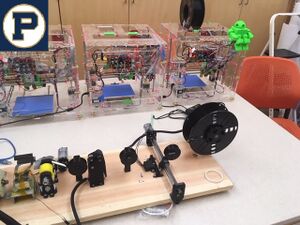

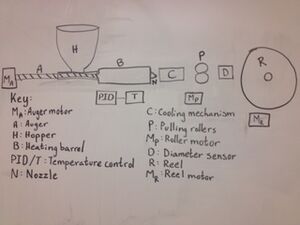

"Filacycle" as it was known by the design team was based off of the RepRapable Recyclebot as well as several other open source filament extruder designs. The overall design was created by researching all of the existing open source filament extruders, constructing a matrix of advantages, disadvantages, local sourcing of parts, total cost for parts, then combining them with original designs from the team. The existing design we drew most heavily upon was the RepRapable Recyclebot. A Hall Effect sensor for precise measurement of filament diameter with its built in feedback system for fine QC on the accurate and consistent diameter of the extruded filament. The project team developed a recycled bottle shredder and completed training on the CAM machining software necessary for using Principia's new CNC mill to machine parts for the extruder and shredder assemblies. Key improvements to the design include:

- Automating the measurement of filament diameter

- Integrating a PID controller into the heating assembly to keep the melt at temperature

- researching various designs for shredding the recycled bottles to obtain the fine granularity needed by the filament extruder

- Completing a bottle shredder that provides adequately sized particles

While these aspects were not completed, improvements in the following areas began implementation:

- Programming a feedback loop to control the filament diameter by varying the speed of the puller motor automatically

- Programming a user interface on the Arduino computer-controlled operating system

Elements that were improved upon include the method of cooling the filament quickly just after extrusion and the Hall Effect sensor for precise measurement of filament diameter with its built-in feedback system for fine QC on the accurate and consistent diameter of the extruded filament.

Troubleshooting[edit | edit source]

Heating Wire:

- Unplug the power supply if not already done

- Extinguish any fire

- Let system cool

- Unplug all connectors to the control board

- Remove soot and find where the wire is damaged (separated or badly burned)

- Take pictures of the spacing of the damaged wire

- Unwrap the damaged portion of wire and remove Kapton tape

- Replace the layer of Kapton tape on the pipe if it has been removed

- Rewrap the wire in a similar pattern to as it was removed using pictures taken cover each loop you do with its own piece of Kapton tape in order to secure and isolate it

- If the wire was damaged away from the connection to the traditional wire splice it back together

- If it was damaged near a connection remove the tan fiberglass tape

- Remove the Kapton tape

- Cut the heatshrink off the wire (be careful not to damage the wire)

- Disconnect the connector pins

- Crimp the new wire

- Cover in Kapton tape wrap tape around the back of the pipe for support

- Cut heat shrink to cover both ends of the connector

- slide the heat shrink over both connectors and melt with heat gun

- Cover in fiberglass tape wrapping around the pipe for added strength

Common Issues[edit | edit source]

- Clogged nozzle

- Auger unscrewing from the motor

- Backpressure pressing melted filament out of the flange

- Puller roller not turning (solved with lock tight)

- Plastic starts to burn at 240 on the PID readout

- 120 v cable came loose from its connector

- Cooling block is not consistently cooling

- Filament is a mess when initially extruded

- Diameter control is currently absent from the design

- The auger needs to be turning at full speed and the right amount of pellets has to be consistently feed in

- When a lot of pellets are fed in back-pressure builds up and back pressure damages the hopper assembly and stops filament extrusion

- The filament can slip and avoid the bearings in the hall effect sensor

- Filament can get tangled in the puller assembly

- Filament diameter is more consistent when both the puller and spooler are running

- Wet filament is very brittle

- Reusing already once extruded filament does not work.

- If the cooling block is malfunctioning the filament will be too warm when feed through the pulled and will get crushed

Conclusion and future improvements[edit | edit source]

The overall goal of this project was to design a filament extruder that can effectively measure and heat a filament mixture of recycled and purchased plastic pellets. In this task, Principia College finds the improvement on other open-source designs to be successful. Future improvements of the design would focus on improving the consistency and reliability of the design to allow for less monitoring.

References[edit | edit source]