Optimized Blade Design for Homemade Windmills

The intent of this project, created in collaboration with Mech425, is to identify the best angle for flat, uniform blades in relationship to the air stream. The angle of the blades should be optimized to convert the most amount of energy into rotational motion. Flat blades are used in conjunction with vertical axis turbines and the design is generally selected when simplicity is preferred or when access to tools and supplies are limited.

- The project has been selected to provide support to individuals looking to generate electricity by harvesting the wind

- The target audience are people who cannot afford commercially available models and have chosen to build their own

Windmills have many functions and can be operated wherever there is access to wind. Windmills use their blades to convert the energy in wind into rotational motion. This rotational motion can either be used for direct work or converted again into electricity. Originally, windmills were used to perform the grinding at mills. Today, they are still used for this purpose but have extended their range of uses to pumping water and electricity generation. In lesser economically developed countries, the electricity generated by homemade windmills is often used to charge batteries and cell phones or operate lighting devices, radios and irrigation pumps.

Modern wind turbines that are commercially available have been tailored to address specific wind speeds and are capable of generating megawatts of electricity from each turbine. However, homemade solutions are often low-tech and have undergone little scrutiny in terms of optimization. This report intends to identify to best angle to tilt the blades in relation to the oncoming wind to generate the most amount of electricity.

William Kamkwamba is a fantastic example of someone who could benefit from the analysis presented in this report. He was able to build the windmill using his ingenuity and a trial and error mentality. He successfully transformed the scrap materials around him into a functional windmill that offers both light and irrigation. His work has provided a better life to his family and friends, while inspiring people throughout the world. However, based on his limited formal education, he did not incorporate engineering calculations to optimize the design. As more people try to harness the potential of the wind, there is great value in optimizing these devices to maximize their social benefit.

For more information about William, his inspirational story can be viewed below:

Benefits of Flat Blades[edit | edit source]

Flat blades are less common than other designs but offer significant benefits, especially in low income or remote areas. The following is a list of benefits offered by utilizing flat blades:

- Easy to build

- Less design and local knowledge required

- Less equipment and time is required during construction

- Easier to ensure blades are a consistent shape and size

Engineering Calculations[edit | edit source]

The kinetic energy stored in the wind can be found according to Bernoulli's Principle:

KE = 1 / 2(m * v2)

In order to find the energy in the wind, we must find the mass of the cylinder. This is based on the volume of the cylinder multiplied by the density of the fluid:

m = ρ * V

The total volume of the fluid that is represented by cylindrical column is:

V = A * L

We can calculate the area of the cylinder's base by:

A = 1 / 4(π * D2)

The length of the cylinder represents the amount of fluid that has passed through the windmill's swept area. This is calculated by multiplying the velocity of wind by time:

L = v * t

This can be simplified as follows:

KE = 1 / 8(ρ * π * D2) * v3 * t

Finally, the power in the wind is simply the energy per unit of time

P = π / 8(ρ * D2 * v3)

As demonstrated, the power in the wind is highly related to the velocity of the air and to a lesser extent the diameter of the blades. The amount of energy in the fluid is related to the velocity of the fluid cubed and indicates the importance of high wind speeds. Therefore, to increase energy output, the most important factor is to find a location with high wind speeds. This can be achieved by creating a tower in order to place the windmill in a more elevated location. This will help to reduce the impact of any obstructions from the ground level. The size of the turbine blades is also important and should also be considered as a method of attaining more power.

Maximum Possible Efficiency[edit | edit source]

The Betz limit was developed by Albert Betz and is intended to represent the maximum possible energy that a device can derive from a stream of fluid at a given speed. In the case of windmill, the maximum theoretical efficiency of a thin rotor can be found based on the following assumptions:

- The rotor is considered ideal, having an infinite number of blades and no drag.

- The flow into and out of the rotor is axial and in accordance with conservation equations.

- The fluid is modeled based on incompressible flow.

The Betz limit has predicted the theoretical maximum value for the power coefficient to be 0.593. This means that the theoretical limit of power removed from the fluid is 59.3%. In comparison, commercial wind turbines are currently able to achieve 40 - 50% conversion due to slight inefficiencies related to the blade design and mechanical process.[1]

Optimal Angle of blades[edit | edit source]

The amount of energy available in a stream of fluid has been indicated below and is closely related to both fluid velocity and swept area of the blades. The other important component is how much energy can be derived from the oncoming fluid. For flat blades, the angle that the windmill blades are tilted compared to the stream of fluid will determine how much energy can be converted into rotational motion and then be captured by the system for meaningful work. The optimal angle has been calculated below:

The wind pressure is the amount of force exerted by the wind per unit area of the blades and is given by: P = 1/2 (1 + c) * ρ * v2

- Where c is a constant and equals 1.0 for long flat plates.

The force of the wind against the windmill blade is based on the wind pressure multiplied by the area of the blade facing the oncoming flow. In the event that the blade is tilted at an angle to the oncoming airstream, then the area of the blade exposed to the fluid is reduced by a factor of sinθ. As such, the wind pressure calculation is multiplied by A * sinθ to obtain the force of the wind on the blades. In addition, the force of the wind converted into rotational motion is related to the angle of the blade in relationship to the oncoming fluid flow. This relationship is given by a factor of cosθ.

Furthermore, the blades will encounter a drag coefficient related to the angle of the blades as they rotate in their own axis perpendicular to the oncoming flow of fluid. This drag coefficient will be represented by D * cosθ.

Therefore, the combined calculation to determine the force balance on the blades is:

F = ρ * v2 * A * sinθ * cosθ * D * cosθ

An important relationship to note is that between force and θ. The combined force balance indicates a relationship between force and sinθ * cosθ * cosθ.

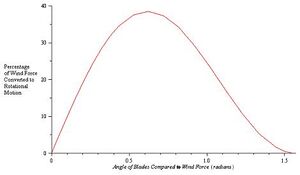

As a result, the optimal tilt of the blades would provide an angle to the airflow such that sinθ * cosθ * cosθ is a maximum. This value has been presented in the graph below to show how the value changes as θ is adjusted.

The angle is adjusted in radians and seems to indicate a maximum value at approximately 0.62 radians, or roughly 35.5 degrees. This translates in a maximum conversion of 38.5% of the wind force into rotational motion. Therefore, the blades should be tilted at an angle of roughly 35.5 degrees from the oncoming air stream to obtain the optimal amount of energy using flat blade windmills.

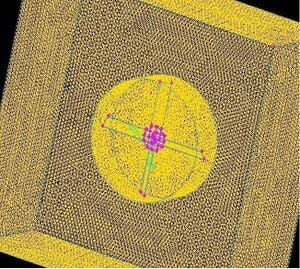

A computational fluid dynamic (CFD) analysis was intended for this blade angle to investigate the pressure distribution and airflow as it passes the blades. Unfortunately, the license for the CFD software, Fluent, has expired. The meshed model of the blade design, using the program Gambit, has been included below.

The completed CFD analysis will be posted once access to Fluent or an equivalent software program becomes available.

Regional Considerations[edit | edit source]

The target regions for this technology are locations where people have limited access to tools or supplies, such as Sub Sahara Africa. In addition, the area must have access to a reasonable wind resource and access to certain key materials. These materials include many technologically advanced materials such as generators and motors. However, these can be found in scrap yards as long as they are functional and can achieve their fundamental requirements. While many people are unable to afford these items, there are many broken down cars and appliances that would be sufficient.

In terms of the social impact, the ability to access electricity is a powerful device that has the ability to help raise communities out of poverty. Conversely, it has been repeatedly shown to create help perpetuate and widen the economic divide. It is important that energy is handles with respect and that it is not used as a tool to further impoverish the unfortunate.

Materials[edit | edit source]

The following list represents the basic materials required to make a windmill either at home or using scrap materials. As William Kamkwamba has shown what is possible and inspired people are the world, the materials he used to build his first windmill are shown below:[2]

If the windmill is being constructed and the intent is to store electricity, then the following materials are also required:[3]

- Deep cycle batteries 12V (If the user intends to store electrical energy)

- Charge controller to regulate how much the battery charges

- DC/AC Converter

- Bridge rectifier (to ensure electricity flows into batteries)

Tools[edit | edit source]

If there are no constraints on the tools at hand, then it would be valuable to have a saw, screw driver, screws, a hammer, nails, washers, nuts and bolts, a level and marker. In addition, the electrical work would be easier with pliers and also voltage, amperage and resistance meters. However, in rural parts of the world people are forced to be more creative with the resources available. Here are a couple examples of how this is the case:[4]

- The flat blades can be created by cutting a PVC pipe lengthwise, using a saw or similar device, and then heating the pipe over a fire. Once hot, it can be molded into a long, flat blade.

- Washers can be made by hammering bottle caps to be flat and then punching a hole through the middle.

In these circumstances, nails, rocks, fire and wood become the tools to build the wind turbine. Steel or rocks can be used as hammers and bicycle spokes can be scraped along a rock to create a flat edge and plastic bags can be melted to build a handle around one end. Furthermore, drills can be created made out of a maize-cob as a handle and an extruding nail. The nail can then be heated over an open fire until it becomes red hot and then be used to penetrate through certain materials.

Skills and Knowledge[edit | edit source]

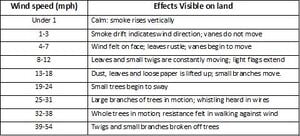

In order to benefit from the energy generating potential of wind turbines, it is important to understand how much wind is available at a given location. A Beaufort scale provides an indication of wind speeds based on various visual clues. While these clues offer indications of the wind speed on the ground, there is likely a greater amount of energy in the wind as the altitude increases. This is based on the boundary layer that develops on the Earth's surface, along with various obstructions on the ground that affect the flow of the wind. The Beaufort scale is provided below:[5]

In order to obtain a more complete list of physical identifying factors, please follow this link.

Furthermore, to transmit the electricity generated to be used for applications such as operating lights, radios or charging batteries, then it is critical to have an understanding of electrical theory such as the required voltage and amperage to power the desired device. An outline of this knowledge can be found here.

Technical Specifications[edit | edit source]

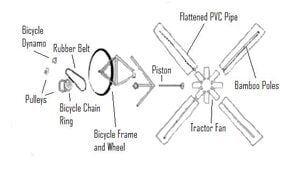

William was able to build his windmill based on the schematic shown below.[6] It was then mounted on a large tower he created out of wood. Overall, the machine is fairly simple in concept with the major limitations being available materials and limited access to tools. Through testing, William found that using his design, a four blade windmill was able to generate more power than its three blade counterpart.[7]

Estimated Costs[edit | edit source]

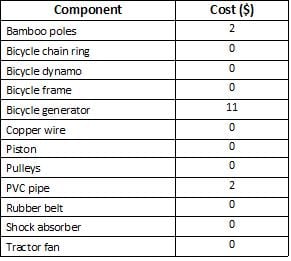

William has disclosed that his windmill cost approximately $15 to produce and that the bicycle generator was the most difficult to attain.[8] An estimate of the costs for the various components has been compiled based on what he has been able to find for free in the scrap yard or from family.

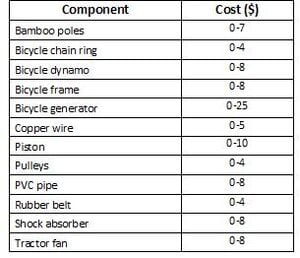

In rural settings, the cost for the parts will vary significantly based on the materials that can be salvaged or must be purchased either locally or from neighbouring villages. Therefore, it is more appropriate to offer a range of anticipated costs based on the variability of how accessible certain materials are. While this is purely an estimate, it offers an idea as to how much one might expect to pay for the parts.

As indicated, the range of costs is approximately $0 - $99 and provides a general range of project costs based on how much can be salvaged. Based on these estimates, William's $15 budget appears to be at the lower end of the range as he was able to find the majority of his materials from what others considered to be waste.

Beyond the initial cost, the power harnessed from the wind has an opportunity to become an income generating technology. Cell phones have provided jobs to many people who rent their phones to individuals looking to call neighboring markets to determine the price for various goods. Similarly, power can be sold to people looking to charge their cell phones or other batteries that can be used for lighting applications or to listen to radios.

Common Mistakes[edit | edit source]

There are many variations to the windmill design used by William Kamkwamba and refined throughout this section. However, there are some variations that are commonly used and have a negative impact on performance. One of these examples is using wood as the material to create blades. Wood is a poor choice as it is a heavier substance and therefore requires more energy to begin rotation and achieve more spin. Other materials should be considered.

Also, it is very important that blades are evenly shaped as this can cause a wobble to occur. The wobble will result in reduced performance and will shorten the windmill's life based on additional vibrations. The windmill blades should also be placed high above all other obstructions in order to obtain a more powerful and consistent wind stream. A good rule of thumb is to place the turbine twice as high as any nearby obstructions.

Other Designs[edit | edit source]

If you happen to have access to additional equipment such as saws and sand paper, then it may be possible to use the design showcased in the video below. Also, be sure to note that the wind turbine is able to pivot and uses a tail to direct the blades into the wind.

References[edit | edit source]

- ↑ Gorlov A.M., Silantyev V.M., Limits of the Turbine Efficiency for Free Fluid Flow, Journal of Energy Resources Technology - December 2001 - Volume 123, Issue 4, pp. 311-317.

- ↑ Kamkwamba, William. The Boy Who Harnessed the Wind.fckLRWilliam Morrow, 2009.

- ↑ Make a Wind Turbine. Available at: http://web.archive.org/web/20210101102628/http://makeawindturbine.com/ [Accessed April 9, 2010].

- ↑ The Doers Club. Available at: http://web.archive.org/web/20100822115207/http://changeobserver.designobserver.com:80/entryprint.html?entry=10707.[Accessed April 4, 2010]

- ↑ The Beaufort Scale. Available at: http://web.archive.org/web/20100822162021/http://gcaptain.com:80/maritime/blog/beaufort-scale-images [Accessed April 4, 2010].

- ↑ The Doers Club. Available at: http://web.archive.org/web/20100822115207/http://changeobserver.designobserver.com:80/entryprint.html?entry=10707.[Accessed April 4, 2010]

- ↑ Kamkwamba, William. The Boy Who Harnessed the Wind. William Morrow, 2009.

- ↑ African Leadership Academy. Available at: http://www.alagapyear.org/community/african_students/williamk.htmlfckLR[Accessed April 16, 2010].