Safety Training Requirements[edit | edit source]

- Dr. Pearce Safety Lab Tour

- Worker Health & Safety Awareness

- WHMIS 2015 - Workplace Hazardous Materials Information System

- Laboratory Safety & Hazardous Waste Management

- List all others

Operation & Procedure[edit | edit source]

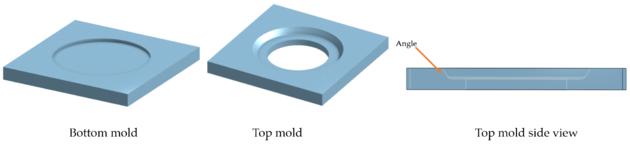

For the assembly of coin cells, using a hydraulic press is essential to effectively press the cases and secure the battery components. In this context, we propose the use of an open-source press specifically designed for this purpose. To facilitate this process, two molds are 3D printed. To ensure that the molds have enough strength, the preferred 3D printing method is SLA (Stereolithography).

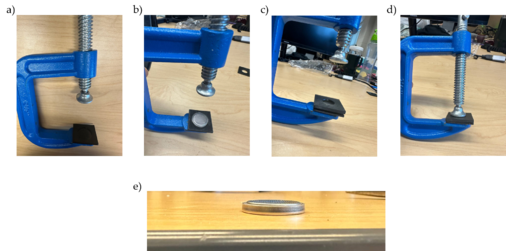

The assembly process is as follows:

a) Glue the "Bottom mold' to the clamp.

b) Place the bottom side of the coin cell case onto the "Bottom mold".

c) Adjust the "Top mold' on top of the coin cell.

d) Apply pressure onto the upper mold to securely fasten the coin cell components.

To optimize this procedure and ensure that the coin cell is entirely secured, a slope is designed onto the upper mold to tilt the edge of the bottom case inward.