Loleta Elementary rainwater

Abstract[edit | edit source]

This page explores the planning and installation of a 4,800 gallon rainwater catchment system at Loleta Elementary School in Loleta, California. The background, problem statement, and project evaluation criteria all serve to define the problem-- the need for more water for irrigation, and how the problem will be addressed-- installing a 4,800 gallon rainwater catchment system. The literature review explores important considerations that must be taken into account when installing rainwater catchment systems, such as material components, local climate, and local governance and planning regulations. The page provides information about the prototyping, construction, operation, and maintenance of the system, including a step-by-step overview of installation. Lastly, there is a discussion of lessons learned and potential next steps in improving and expanding the system.

Background[edit | edit source]

Loleta Elementary School grows food for its students in a garden that is cared for by onsite staff. The school plans to also add a small fruit orchard in the near future. When the fall season arrives, the school offers the community a pumpkin patch, effectively generating an additional source of revenue. Both of these agricultural activities require continued irrigation. Rather than having irrigation water provided by the municipality, Loleta Elementary School wishes to install a rainwater catchment system to support their irrigation needs and reduce costs.

Problem statement[edit | edit source]

Previous to installing this system, one of Loleta Elementary School's biggest expense was water, especially for their garden and pumpkin patch during summer months. The objective of this project is to install a rainwater catchment system that will reduce the cost of irrigating the garden and pumpkin patch, and also act as an educational tool for the school and the community.

Project Evaluation Criteria[edit | edit source]

The following Criteria will be used to assess the success of this project. These criteria were chosen by the team and staff members from Loleta Elementary. The scale (1-10) represents the importance level of meeting the constraint of each listed criteria.

| Criteria | Constraints | Weight (1-10) |

|---|---|---|

| Safety | Will not cause a danger to students or staff. | 10 |

| Functionality/Effectiveness | Must provide enough rainwater to the garden to grow food for the school and drastically reduce the schools water bill. | 10 |

| Adaptability | Be able to be modified if needed. Be able to build off of to install a water bottle filling station in the future. | 7 |

| Cost | Supplies and materials must cost less than $1,000 US dollars. | 2 |

| Maintainability | Be able to be kept in good condition by the experienced grounds keeper | 5 |

| Durability | Be able to last several years with general cleaning and maintenance | 8 |

Literature Review[edit | edit source]

This is a review of the available literature pertinent to our project.

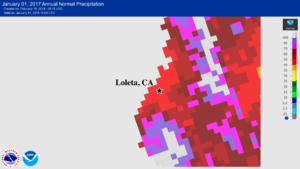

Local Climate[edit | edit source]

The average precipitation of Loleta ranges between 40 in. to 50 in. annually.[1] On average, Loleta experiences rainfall events of more than 0.1 inches approximately 89.1 days out of the year. On the contrary, Loleta experiences 177 days that are predominately sunny.[2]

Material Components[edit | edit source]

Conveyance[edit | edit source]

Carries water from roof catchment area to storage tank (in the case of a "built" system), or directly to the ground area where the water will be used (in the case of "natural" systems). Conveyance components include, generally, gutters and downspouts. The most common and affordable Gutters/downspout materials are made of: bamboo, galvanized sheet metal, or PVC (either intact or cut in half). (Grafman, 16, 2017). Material appropriateness varies based on the type of system, availability, affordability, and aesthetic considerations. It's also important to consider the Social, economic, and environmental aspects of the circumstances under which the system is being installed. (Gould, 1999)

Storage[edit | edit source]

Storage tanks vary in size and material composition, and choice of storage tank depends upon catchment potential of roof surface, and the specific use of the water. Types of storage containers for built systems include: Plastic storage tanks, Commercial rainwater tanks, 55-gallon drums, Ferrocement tanks (made of cement or lime mixed with sand, applied over metal mesh), and intermediate bulk containers (Grafman, 16-18, 2017). Determining Daily maximum precipitation is a key factor in determining what types of materials to use and what size tank to install, to be sure that the system doesn't become damaged or overloaded. (Yi Li et al, 2018).[3][4][5]

Roofing Materials[edit | edit source]

Rainwater catchment surfaces can include thatch, tile, corrugated metal, asphalt, concrete, standing seam metal. Catchment efficiency depends on roofing material, with corrugated metal and standing seam metal being the most efficient (approx. 95% efficiency) and thatch and tile being the least efficient. Water safety also varies based upon roofing material, with asphalt and thatch being lowest safety and tile and standing seam metal being highest. The safety of corrugated metal varies based on coating. (Grafman 8, 2017). Copper roofs are not suitable for rainwater collection. Likewise, galvanized steel, which contains zinc, is not suited for rainwater collection. (Kinkade-Levario, 2007)

Local Governance & Planning[edit | edit source]

Loleta is not an incorporated city, therefore all development is regulated by Humboldt County Planning and Building Department. Developing water storage structures requires permits from local agencies depending on the size and scale. Water storage structures that exceed 5,000 gallons require a permit from the Humbodlt County Building Inspection Division.[6] Fees and payments associated with the required permit varies depending on the storage size, number of referral agencies, and total number of permits.[7]

Building Permits[edit | edit source]

Water storage structures that exceed 5,000 gallons require a permit from the Humbodlt County Building Inspection Division. Building Permits may take approximately 4 to 6 weeks to get approved.[6]

Conditional Use Permits[edit | edit source]

If the water storage structure exceeds 50,000 gallons, then a Conditional Use Permit from the Humboldt County Planning Division can be acquired. A Conditional Use Permit may take approximately 4 to 6 months to get approved.[6]

Water Filtration[edit | edit source]

Different components will remove debris and initial pollution from the rainwater. Having a screen in place will separate debris from the water and having a first flush system will remove the dirtiest water from going to the storage tank (Grafman, 2017). By removing more containments before the water gets to the storage tank, the easier it will be to maintain and clean the tank[8] (Allen Novak, 2014). If the end use will be drinking water, however, more filtration will be needed.

Filtration Type 1- Chlorine[edit | edit source]

Chlorine can be used to kill a wide range of disease causing organisms in water. It is commonly used but can be hazardous at certain levels and even at safe levels, leave a taste in the water (Grafman, 2017).

Filtration Type 2 – Slow-sand filters[edit | edit source]

A layer of biological material, Schmutzdeck, on top of layers of sand and gravel. This method takes longer to filter water but is a good option for projects with smaller budgets and can be used for drinking (Grafman, 2017).

Design and Prototype[edit | edit source]

We prototyped our system minimally, here is an example of the physical prototype we made:

- In order to size our downspouts, first flush, and calculate catchment volume needed, we referred to Lonny Grafman's book ''To Catch The Rain, which provides in-depth instruction on the process of designing a rainwater catchment system

- Although we attempted to use the rules provided in To Catch the Rain for all of our sizings, some exceptions were made due to the existing infrastructure of the site:

- we used 2-inch pipe rather than 3-inch pipe because pipe size is calculated based on maximum rainfall events, which are rare in the area of Humboldt County, CA. Additionally, the existing gutter was too narrow to accommodate the installation of a 3-inch pipe, so we chose to use smaller pipe rather than replacing the gutter itself.

- We learned that more thorough prototyping and testing before installation would have made the installation process easier and the final product immediately more effective

- We had to revisit the site several times to be sure that the system was functional and to change errors that we made in our original installation

Construction[edit | edit source]

Instructions[edit | edit source]

Install the first flush: attach a 90 degree connector to conveyance pipe so that the pipe turns toward the storage tank. Connect 2 feet of pipe to the 90 degree connector. Connect a T branch connector to that and attach another 2 feet (or appropriate length) of pipe on the other side to connect to the catchment tank. From the bottom of the T branch, connect a short length of 2" PVC, attach a 2"-->3" adapter followed by 3 feet of 3" PVC. Place a ball that will float inside the 3 inch PVC and connect a 2"-->3" adapter to a short length of 2 inch PVC. Connect this length to bulkhead fitting in bucket lid.

Timeline[edit | edit source]

A tentative timeline for our project. We will do each task on the date listed below or have completed the task by the date listed.

| Date | Task |

|---|---|

| 3/4/18 | Prototype, proposed timeline, budget |

| 3/12/18 | Materials list (what's needed/what we have) |

| 3/17/18 | Have all materials |

| 3/23/18 | Finish project testing and design |

| 3/25/18 | Start construction |

| 4/8/18 | Draft Appropedia page |

| 4/22/18 | Have construction completed |

| 5/1/18 | Final Appropedia page, final video |

Costs[edit | edit source]

All of our materials (except the plastic ball used for our first flush) were donated from Pierson's home center In Eureka, CA and Bandera Water Tanks in Fortuna, CA.

| Quantity | Material | Source | Cost ($) | Total ($) |

|---|---|---|---|---|

| 1 | 15' 2" pvc pipe | Pierson's Building Center | 00.00 | 00.00 |

| 2 | 90° 2" PVC connector | Pierson's Building Center | 00.00 | 00.00 |

| 1 | 2" T adapter | Pierson's Building Center | 00.00 | 00.00 |

| 7 | 2" PVC connectors | Pierson's Building Center | 00.00 | 00.00 |

| 2 | 2"-->3" PVC adapters | Pierson's Building Center | 00.00 | 00.00 |

| 1 | 5000 gallon tank | Bandera Water Tanks | 00.00 | 00.00 |

| 1 | PVC glue | Pierson's Building Center | 00.00 | 00.00 |

| 1 | downspout filter | Pierson's Building Center | 00.00 | 00.00 |

| 1 | 2" hole saw | Pierson's Building Center | 00.00 | 00.00 |

| 6 | 2" stainless steal 2 hole rigid conduit strap | Pierson's Building Center | 00.00 | 00.00 |

| 1 | JB weld | Pierson's Building Center | 00.00 | 00.00 |

| 1 | 5 gallon bucket | Pierson's Building Center | 00.00 | 00.00 |

| 1 | 3' of 3" PVC | Pierson's Building Center | 00.00 | 00.00 |

| 1 | 2.5" light hollow plastic ball | Dollar Tree | 1.00 | 1.00 |

| Total Cost | $1.00 | |||

Operation[edit | edit source]

Here are step-by-step instrcuctions of how to operate this system.

Take the rainwater collected by the system from the faucet located at the bottom of the tank. An adapter can be attached to the faucet to allow a hose to be attached.

- This water is not suitable for drinking or for root crops

- This water can be used for watering non-root crops and for other irrigation purposes

Maintenance[edit | edit source]

Rainwater catchment systems require regular maintenance for optimal longevity and functionality.

Schedule[edit | edit source]

| Activity | Frequency |

|---|---|

| Check that first flush is draining properly and that there are no leaks or breaks in the system | Monthly |

| Clean Gutter | Monthly for first year to determine schedule |

| Clean downspout screen | Monthly for first year to determine schedule |

| Empty and clean the first-flush (take off the lid and wash the bucket) | Twice a year or if clogged |

| Inspect integrity and functionality of the whole system, and replace or clean components, if necessary | Yearly |

| Empty and clean the tank, scrubbing off any sediment build-up | Every 3 years |

Conclusion[edit | edit source]

Testing results[edit | edit source]

We tested the system using a hose because there was no precipitation for testing. After our initial installation, we noticed that the first flush was leaking but did not have the equipment to fix it on sight. In addition, the ball we used in the first flush did not appear to float. Otherwise, our system appeared functional.

Discussion[edit | edit source]

After discussing with our instructor, we realized that our initial design was to simply glue a 2" pipe into the first flush bucket. Our instructor informed us that this connection carries a lot of pressure and that we would have more success using a bulkhead fitting. We returned to the site and installed a bulkhead fitting onto the lid of the first flush, we also replaced the ball we used initially with a lighter ball which is more bouyant. The first flush functioned well after these changes.

Lessons learned[edit | edit source]

- Stay in better contact with the client, do not be afraid to contact the client repeatedly.

- Have a complete project design with accurate prototyping before starting construction, this will save a lot of time and energy.

- Be more thorough in data collection on-site before construction.

- Take more detailed photos of the construction process for better documentation.

- Double check measurements before cutting pipe, drilling holes, etc.

- Start construction earlier.

Next steps[edit | edit source]

- The overflow needs to be connected to a hose or downspout in order to direct the flow to a useful location, or at least a location that won't cause swampiness or erosion.

- The valve for releasing water needs to be adapted for hose use.

- The irrigation system must be altered for compatibility with the catchment system.

- The client would like to install an additional catchment system connected to another structure on the property. They have already been donated an additional 5000-gallon tank to do so.

Troubleshooting[edit | edit source]

Here is some information on troubleshooting basic operations. For more information on similar projects, refer to Lonny Grafman's book To Catch the Rain, available free at [1]

| Problem | Suggestion |

|---|---|

| Tank does not seem to be catching rain during a rainfall event | Check downspout and screens for clogs or buildup, check conveyance and first flush for leaks |

| Water is not clean | Clean gutter and downspout, clean and check the first flush, clean screens, check the schedule to see if it is time to clean the tank. |

| First flush not catching water | Check to be sure that there are no leaks and that joints are secure, make sure that the ball is floating |

| First flush is not draining | Check to see if the small hole at the base of the bucket is draining, take off bucket and clean, unclog the hole. |

Team[edit | edit source]

Update[edit | edit source]

A follow up visit was made September 20th 2019 to Loleta Elementary School to get an update on their water catchment system. The purpose of their system was to grow food for its students, provide a community pumpkin patch, and start a small fruit orchard. To accomplish this they needed to reduce the cost of irrigating the gardens and the best way to do that is by catching their own rainwater. This project has been a huge success and has brought the community closer. A lot has come from having the water catchment system for the school and community such as receiving grant funds for expansion and the purchase of a tractor which is a huge help to the caring staff members overseeing this project. Education for the kids and families about growing your own food is another advantage. Classes rotate doing different activities in the garden and learning experiences are created for the families. A greenhouse is newly constructed on the site which is going to provide a large area for more crops. They are planning on winter crops this year. It'll be exciting to see what they grow. There is a strip along the fence line that has been recently tilled, ready for the small orchard of fruit trees which they have 9 trees of all different varieties ready to be planted. This fall they have corn, squash, pumpkins, and sunflowers growing. The crops they grow are all used by either the school or the community. Nothing goes to waste. The school is able to provide free breakfast, lunch, and two snacks every day for the students. Food is also sent home for families. The school also has fundraisers and community gatherings where families and community members can go and pick all the food they need. Without this water catchment system, its difficult to imagine everything they have accomplished being done. Would not be possible without the water catchment system. It has provided them all the water and more necessary to achieve their goals. That being said, they have yet to run out of water. The only negative is the first flush was recently damaged and seems to happen quite often. It is missing in the updated photos but will be replaced soon. The site contact is trying to get some fencing donated to put around the tank to keep the kids from running through the space where the first flush is located. Loleta Elementary School is a great example of what can be done at every school with the right leadership.

-

Fall 2019

-

thumb

-

thumb

-

thumb

-

thumb

References[edit | edit source]

- ↑ 1.0 1.1 http://water.weather.gov/precip/#

- ↑ http://web.archive.org/web/20160713185700/http://www.bestplaces.net:80/climate/city/california/loleta

- ↑ Kinkade-Levario, Heather. Design for Water: Rainwater Harvesting, Stormwater Catchment, and Alternate Water Reuse, New Society Publishers, 2007. ProQuest Ebook Central, https://ebookcentral.proquest.com/lib/humboldt/detail.action?docID=316343.

- ↑ Gould, J., & Nissen-Petersen, E. (1999). Rainwater catchment systems for domestic supply: Design, construction and implementation. London: Intermediate Technology Publications.

- ↑ Li et al., "Multi-Objective Optimization Integrated with Life Cycle Assessment for Rainwater Harvesting Systems."

- ↑ 6.0 6.1 6.2 https://humboldtgov.org/documentcenter/view/6565

- ↑ http://humboldtgov.org/documentcenter/view/51632

- ↑ https://ebookcentral.proquest.com/lib/humboldt/reader.action?docID=1650821&query=