Improving system efficiency by combining engines

The efficiency of a fuel conversion system can be improved by combining 2 or more engines together (this being known as a "combined-cycle system"). This works in that waste heat energy from one engine is used as a "fuel" for the other. The second engine in effect hence harvests energy from the first engine. It hence differs from Cogeneration & Trigeneration as these latter types simply spread waste energy in rooms (space heating) and do not use the heat to power an extra engine (ie to provide mechanical work or electricity).

This article focuses on what combined-cycle combinations can be used, and compares the combinations of engines with each other. Note that the combinations electric engine-heat engine have not been included as they don't harvest waste energy from each other. Instead, this engine combination is just more efficient in that in certain areas (ie crowded areas/cities) the full motor efficiency of the heat engine can't be attained. This, due to the many stops, starts, decreases in motor speed, increases in motor speed, ... Electric motors are generally a lot better in this task, making the use of this motor in these environments useful and increasing the efficiency of the system as a whole.

Combining piston steam engines[edit | edit source]

The compound engine, although considered to be a single engine, can also be seen as an assembly of piston steam engines. This as it uses several pistons, one after an other. Unused steam energy in the steam coming from one piston is reused in the next piston. The system though is not generally more efficient than 15% (same efficiency of a single piston steam engine), as through careful dimensioning of the water quantity, size of the heater tank, ... no surplus waste heat energy should exist that could be used by subsequent pistons.

Combining IC engine and steam engine[edit | edit source]

An internal combustion (IC) engine (gasoline or Diesel) can be combined with a steam engine so that waste heat energy from the IC engine can be used by the steam engine. The efficiency of this is 30% (gasoline IC engine) or 35%-50% (Diesel IC engine) + 15% (steam engine) = 45% to 65% Some commercial systems have already been made.[1]

Combining IC and Stirling engine[edit | edit source]

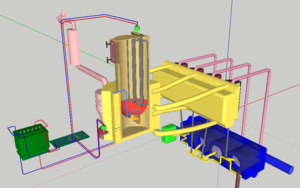

An internal combustion (gasoline or Diesel) engine can be combined with a Stirling engine so that waste heat energy from the IC engine can be used by the striling engine (see Fig. 1). The efficiency of this is 30% or 35%-50% (respectively gasoline, Diesel IC engine) + 40% (Stirling engine) = 70% or 75%-90%

Combining a internal combustion (IC) engine with a Stirling engine is useful for already owned IC engines, for both stationary use and use in vehicles. Purchasing new IC engines to set up such a system is only useful if the engine assembly is to be used for stationary applications. This, as IC (Diesel)/(Alpha-)Stirling engines have a longer life span/less breakdowns than gasoline and Beta-Stirling engines. Vehicles however better use either a single engine -as this is lighter and use up less space- (ie Stirling engine) or -if a comparable efficiency is needed- a combination of a light IC and Stirling engine (ie Quasiturbine and Beta-Stirling engine).

Notes[edit | edit source]

Note that a differentiation needs to be made between Diesel engines. In general, we can distinguish 2 main types: the 4-stroke Diesel engine and the 2-stroke Diesel engine. Both need to have indirect injection as direct/unit-direct injection does not allow the use of low-grade fuels (ie low-quality plant oils, ...) The 4-stroke Diesel engine equipped with indirect injection only attains a efficiency of 35%, whereas the 2-stroke Diesel engine (of the uniflow crosshead type can attain 50% efficiency, and run on any type of liquid fuel.[2] Note that the 2-stroke Diesel engine is only useful for stationary applications, as they are very heavy. They have been used in ships, as in these vehicles, the extra weight of the engine doesn't matter as much as in ground vehicles, as vehicles on water already experience a weight reduction. Regardless, they are nonetheless best not used for this as weight still plays a role (although a lesser one).

Also note that the high efficiencies can only be reached when they attain their optimal speed/load ratio, see Electric and hybrid electric vehicles