Flock House EcoDermis

Flock House, the client, contacted Cal Poly Humboldt to build various parts of a new alternative living structure in New York City. Team EcoDermis was formed in order to create a solution for a weatherproof shell as well as coverings for the openings of the the structure. Multiple alternative solutions were formed through group brainstorming. These alternatives were put through a process to determine which solution best fulfilled the criteria. Discussion with the client led to a decision of a combination of two alternatives. The Bird Cage forms the main weatherproofing shell while the Plastic Plumage covers the window openings.

Background[edit | edit source]

The Flock House project is a concept to provide a new form of housing for different migrating populations throughout the world. These structures demonstrate an inspirational method to use repurposed materials to construct everything needed to function in a modern society. It shows a new way to come together as a community and work together to help the individual and the community. The Flock House will inspire community interdependence and resourcefulness. Mary Mattingly is the voice of the client that we worked with on the project. Mary and other professionals, engineers, builders, teachers, designers, and architects built a similar sustainable living environment called the Waterpod Project. This is a floating barge that moved around the boroughs of New York to show a sustainable living culture. The Flock House is a mobile structure for land that will be able to link up with other Flock Houses. Each Flock House will have a skin/shell to protect it from the elements as well as alternative energy sources, bike power charging stations, a solar dehydrator, and a power meter to display the power used and stored.

Problem Statement & Criteria[edit | edit source]

Problem Statement[edit | edit source]

The Flock House needs to be covered with a skin or shell that meets the criteria listed below. The Flock House will be inhabited by 2 artists and the skin needs to have the main function of protecting the occupants from the elements outside and providing them with privacy.

Objective[edit | edit source]

Flock House needs a waterproof skin made from material that is inexpensive, sourced from reused materials, able to be produced by someone with moderate technical skill, and suited for a variety of weather conditions.

Criteria[edit | edit source]

The criteria for the skin of the Flock House was created from a problem analysis and through communication with the client. Each criteria is weighted with its designated importance. The scale is from 1-10 with 10 being the most important.

| Criteria | Weight | Description |

|---|---|---|

| Weatherproof | 10 | Needs to keep occupants dry and sheltered from the wind |

| Repurposed Material | 10 | The more materials that are recycled and repurposed the better |

| Safety | 9 | Structure has to be stable as to not harm the occupants |

| Durability | 8 | The shell has to be able to withstand normal wear and tear from travel or be easily replaced. |

| Aesthetically Pleasing | 8 | Has to be visually appealing and attract the attention of passersby |

| Reproducable | 7 | Should be able to be reproduced by as many responsible adults as possible |

| Lightweight | 7 | The shell should not add so much weight that six strong people could not lift a Flock House |

| Translucent | 6 | Needs to allow enough light through so the occupants can see well while inside |

| Educational | 6 | Should show visitors a new way to look at building and living in new structures |

| Cost | 4 | Should cost less than $375 for the shell to be made |

Description of final project[edit | edit source]

The final project decision is a combination of The Plastic Plumage to cover the windows and The Bird Cage for the outer shell.

Plastic Plumage[edit | edit source]

Plastic Plumage is a way of using empty one gallon milk cartons in a new way to cover the windows on the Flock House. The layering of each string of plastic shingles allows for a fluttering effect when wind is present. These shingles provide a moderate amount of water protection while still allowing light and fresh air in.

-

One window with plastic shingles

-

Construction continues

-

Inside view of shingles

Bird Cage[edit | edit source]

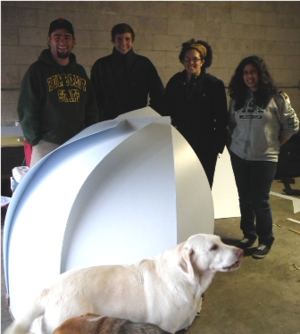

The bird cage is a spiral hemisphere made out of recycled corrugated plastic. Each piece is overlapped by at least two inches on the bottom and wraps around itself in a layering style that is very visually appealing and so attracts attention to the Flock House.

-

Bird Cage closed

-

Door opened to allow access

-

Top view of Bird Cage

-

Bird Cage unfolded

Cost and Materials[edit | edit source]

Design Cost[edit | edit source]

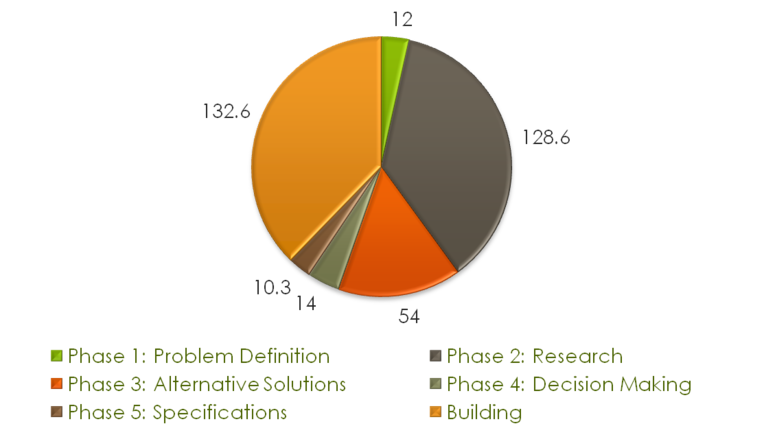

Design cost is measured in hours. The total hours spent on the creation of the skin for the Flock House are 352 with the total being broken into respective segments as shown in the pie chart below.

Implementation Cost[edit | edit source]

The implementation cost is what it cost Team Ecodermis to construct the Plastic Plumage/Bird cage Combo and what a retail cost would be.

| Item | Quantity | Our price per item ($) | Total | Quantity | Clients estimated price per item ($) | Total |

|---|---|---|---|---|---|---|

| Corrugated Plastic Sheets | 9 | 8.07 | 72.63 | 12 | 14.00 | 168.00 |

| Chicken Wire | 1 roll | 0.00 | 0.00 | 0 | 0.00 | 0.00 |

| Crimp Sleeves | 48 | 0.25 | 11.96 | 144 | 0.25 | 35.88 |

| 1/4 inch eye bolts | 30 | 0.90 | 27.00 | 50 | 0.90 | 45.00 |

| 1/16 inch metal wire per foot | 15 | 0.08 | 1.20 | 50 | 0.08 | 4.00 |

| Corrugated plastic shipping | 1 | 28.00 | 28.00 | 1 | 35.00 | 35.00 |

| 1/2 inch pvc pipe 10 feet | 4 | 1.79 | 7.16 | 0 | 0.00 | 0.00 |

| Wood handle | 2 | 0.20 | 0.40 | 2 | 0.20 | 0.40 |

| 1/4 inch by 4 inch eye bolt | 1 | 1.79 | 1.79 | 1 | 1.79 | 1.79 |

| Total Cost | $150.14 | $290.07 | ||||

Data/Results[edit | edit source]

Placing a tub inside the structure allows us to measure how much water can seep through. Putting newspaper throughout the tub allows for detection of water leakage. Using a water hose and a spray nozzle we showered the Bird Cage for 30 minutes. The results were that the edges of the structure got wet from water running down the sides of the corrugated plastic and collecting in a ring on the outside. This would be a good area for the Flock House to make a water collection system most efficient.

To get a true wind test result, we took our structure to an open field to allow for as much unobstructed wind as possible. According to our altimeter the wind varied between 6 and 15 MPH. Due to the lightness of the structure, we used 100lb to weigh it down to see how the panels held up under the wind force. The wind produces enough force on the panels to cause tearing around the bolts. A rubber grommet should be added where the bolts pin the bottoms of the plastic together.

DIY[edit | edit source]

How to Build Your Own!!

Step by Step Process[edit | edit source]

Drilling up through the PVC supports of the structure creates a hole for the pivot bolt to go through. We used a 4"x1/4" eye bolt for this purpose. Since the Flock House is a fiber glass shell we recommend using an appropriate size screw bolt or in the forming of the fiber glass a metal rod can be molded into the structure. The smaller the diameter of the rod the better as to not allow water seepage.

After the top of each sheet is attached, take off the pieces of wood holding them on and replace with a 2"x1/4" eye bolt. These will hold the pieces of corrugated plastic together at the bottom. For the Flock House itself the idea is to place a runner along the inside of the wooden truss system that the bottom of the sheets could lock into.

Since all the pieces of the corrugated plastic can hinge around the middle rod you can pivot them around to stack on top of each other to allow air inside the structure. Seal each edge of the corrugated plastic with weather stripping. Find a weather strip with a peel of sticky backing. This will seal tightly to the plastic. If the weatherstripping is a foam like substance use beeswax to line the edge to help water run off and way from the seams.

References[edit | edit source]