Bicycle-mounted mill and pedalling grinder

These mills have been developed by the TDRI, Tropical Development Research Institute, England.

These two devices (see image 23) are both very similar. In the first case, the mill is mounted on a bicycle, while in the second case, the bicycle has been replaced by a wooden frame.

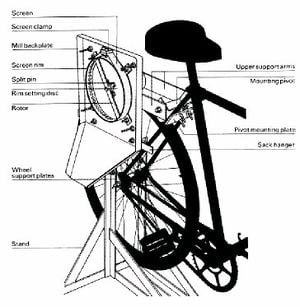

The mill itself is based on a principle which is very similar to the conventional hammer mill. The operator pedals at a "normal but still supported" speed. The wheel then drives the axis of the mill at a speed of 5000 rpm (which corresponds for operator to a speed of about 25 km/h). An arm (hammer, or "rotor", see image 24 below) is attached to this axis and the grain is grinded when struck by the end of this arm. A easily removable grid (or "screen" in image 24 below), allows one to choose the fineness of the flour depending on the desired size of the meshes. For a given effort, the throughput depends on the desired fineness. According to TDRI, the mill works best for hard and brittle grains like maize, millet, sorghum and soybeans.

-

Bicycle-mounted mill and pedalling grinder. After "A pedal-operated grain mill, Rural Technology Guide 5, Pinson G. S., Tropical Products Institute, London, 1978, 32 p., ISBN : 0-85954-076-6"

-

Construction details of the drivetrain of the grinder. After "A pedal-operated grain mill, Rural Technology Guide 5, Pinson G. S., Tropical Products Institute, London, 1978, 32 p., ISBN : 0-85954-076-6"

About these mills, it is worth noting the following (after "Traitement des céréales, UNIFEM, New-York, USA, 1989, 75 p., Coll.: Manuel de technologies du cycle alimentaire, n° 3 , p.35,), a case study in Tanzania:

- The TDRI mill was originally designed to be used on the bicycles of the villagers. But if they do have bicycles, they can not use the mill. To proceed to the testing, bicycles have been provided. The results were not satisfactory because the villagers believed that for the grinding of the maize they had wasted a good bicycle. They removed the mill and used the bike for other purposes. It is important to note that the shelling of the grain is a task for the women and that the men do not see the need to facilitate their work using a bicycle.

- Women were generally not prepared to use a bicycle. Traditionally, it are the men who use them and the villagers were embarrassed to use this device. They were so reluctant to use bicycles, that some even put themselves on their knees to turn the pedals by hand.

- We attempted to circumvent these social difficulties by introducing a pedal mill mounted on a wooden frame made by the Arusha Appropriate Technology Project. But this initiative failed because the frame was not strong enough and it was very uncomfortable when pedaling.

- Neither TDRI models are still used today, and the villagers seem to show no interest in pursuing this experience. The quality of the flour produced by the mill is quite satisfactory, but the efficiency is very low. Again maize is the most difficult grain to treat and it requires two or three grindings. It takes 2 to 4 hours to produce one kilo of maize flour.

It showed that the TDRI mills were not appropriate for Tanzania. "

The list of equipment, as well as the plans and the construction stages of the mills are available in the reference No. 21 and in the documentation provided in conjunction with this document. Unfortunately, no information is given on the quality of the obtained flour, throughput and the average price of construction.