The purpose of this project was to create a portable, collapsible, disc golf station primarily from materials diverted from the waste stream. The project also must be reproducible so it can be integrated into the curriculum at Zane Middle School to further educate students on sustainability and the use of upcycled materials. To do this, the project was divided into five parts: Problem Formulation, Problem Analysis and Literature Review, Alternative Solutions, The Decision Process, and The Specifications of the Final Solution.

Background[edit | edit source]

For our Cal Poly Humboldt Spring 2014 Engr205 Introduction to Design project we must build a disc golf basket for Zane Middle School. Zane Middle School is a S.T.E.A.M. School, which stands for science, technology, engineering, art, and mathematics. This rigorous program enriches students and prepares them for living and working in the 21st century.

Problem statement and criteria[edit | edit source]

The objective of this project is to design a portable disc golf station from upcycled materials. The design of the station will be based upon Professional Disc Golf Regulations and criteria given by the client, Zane Middle School.

Criteria[edit | edit source]

The criteria and constraints developed with Zane Middle School are shown below in table 2. The criteria and constraints subsection provides measureable goals which will be used to determine the quality of the project.

| Criteria | Constraint | Weight |

|---|---|---|

| Cost | Less than $75.00. | 8 |

| Aesthetics | School colors, as appealing as the average disc basket. | 6 |

| Safety | Stable (won't tip over if pulled on by a kid), no sharp edges. | 10 |

| Design Specs | At least 70% upcycled materials, collapsible, regulation size, less than 50 lbs. | 7 |

| Durability | Withstand Eureka weather and wear from use for at least 3 years. | 9 |

| Reproducibility | Reproducible by students led by teacher. | 5 |

Description of final project[edit | edit source]

The Decked-Out Disc Catcher, fully diagrammed in Figure 2 is the final design for a disc golf basket. The main components of the basket are a 55 Gallon HDPE drum, 3 skateboard decks, chain, and PVC pipe. It is PDGA regulation size, collapsible, and upcycled.

-

Figure 1: Decked-Out Disc Catcher

-

Figure 2:Decked-Out Disc Catcher fully diagrammed

The Basket: The basket is designed to catch discs without damaging them. The top of the basket is made by cutting the bottom 4" off of a standard 55-Gallon HDPE drum. Every 6", there is a hole drilled ½" above the cut, numbering 12 in total. These serve as the attachments for the s-hooks, which hold up the chain. The top of the basket is attached to 3' of 2" schedule 40 PVC pipe via a 2" flange. The 12 chains are cut into 24" segments. The bottom of the chains connect to a 5" metal ring which hangs around the PVC pipe connecting the top to the bottom of the basket. The bottom of the basket is made from the top 8 inches of the HDPE drum. The bottom of the basket is attached to the PVC pipe with a 2" flange.

The Base: The base is designed to support the weight of the basket without falling or wobbling. Our base consists of 3 standard skateboard decks affixed to the bottom of the basket using hinges. The hinges are attached every 25½" of the circumference. This tripod design provides sturdy support, and also allows the skateboard decks to fold up against the bottom of the basket.

Costs[edit | edit source]

Design Time Input[edit | edit source]

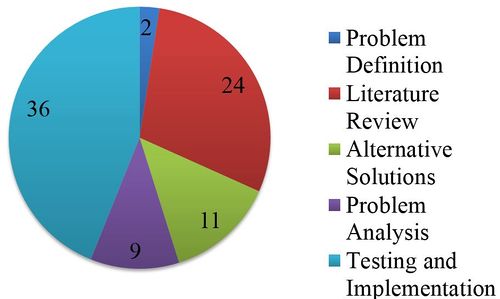

The design costs for hours is the amount of time spent working on the project. The total is 82 hours spent on the project. The most time was in the testing and implementation phase.

82 Total Hours[edit | edit source]

Maintenance Costs[edit | edit source]

The only maintenance is possible repair costs. These repair costs will depend on the part that is broken. The price can be found in the previous table. The nature of the project is using up-cycled materials, so there will not need to be maintenance cost for most of the parts.

Material Cost[edit | edit source]

| Quantity | Material | Source | Cost ($) | Total ($) |

|---|---|---|---|---|

| 1 | 55 Gal. Drum | Arcata Scrap | 0.00 | 0.00 |

| 2 | Hinge x 2 | Ace Hardware | 10.76 | 10.76 |

| 2 | S hooks x 6 | Ace Hardware | 5.38 | 16.14 |

| 1 | Schedule 40 PVC - 2" x 5' | Arcata Scrap | 5.00 | 21.14 |

| 1 | 70ft. Chain | Home | 0.00 | 21.14 |

| 1 | 8' Steel pole | Arcata Scrap | 7.00 | 28.14 |

| 1 | 5' Aluminum pole | Arcata Scrap | 3.00 | 31.14 |

| 8 | Skateboard Decks | Arcata Skate Shop | 0.00 | 31.14 |

| 1 | Schedule 40 PVC - 1.5" x 5' | Arcata Scrap | 5.00 | 36.14 |

| Total Cost | $36.14 | |||

Testing Results[edit | edit source]

Testing the Decked-Out Disc Catcher showed that it was indeed a sturdy and reliable design. The design catches discs without damaging them and without the basket tipping over.

How to build[edit | edit source]

Discussion and next steps[edit | edit source]

After our research we concluded that plastics such as PVC and HDPE were the best option for the basket. Testing showed that the hinges we originally used were much to weak. They bent and twisted under the stress, causing the entire basket to become wobbly and unstable. This design flaw was solved by using heavier-duty hinges. Field use by large groups of middle school students of the disc golf target will show how long it can withstand the inclement weather of Eureka and any other design flaws.

Update October 2014[edit | edit source]

After speaking with Trevor Hammons, a counselor at Zane Middle School, we (Desiree and Cole) discovered that this disc golf basket is not currently in use at the school. Trevor explained that the ultimate goal of the project was to be able to have a disc golf course across the campus, which was not really possible with the single basket. According to Trevor, the basket was also "not as portable as it could be" due to the skateboard decks. A suggestion to anyone interested in constructing this or something similar would be to build more than one so you can have a whole course to play. The disc golf caddy is shown below in its compacted form to the right and its upright form to the left.

-

Disc golf basket when put together

-

Disc golf basket when collapsed for storage