Abstract[edit | edit source]

How can you bring a classroom nearly anywhere? Parties at Catherine L. Zane Middle School and Cal Poly Humboldt were pondering that very question. Team Yerba Mates and one other team were tasked with answering that question. After some deliberation Yerba Mates decided to focus on the instructor's portion of the classroom. The team went through several brainstorming sessions and determined that the most basic functional aspects of a classroom required by an instructor would be a level surface on which to store lecture materials and a writing surface to convey information to students. Due to frequent rain and winds in Humboldt County the client, Zane Middle School, requested the system be portable and storable. Yerba Mates finally decided on a fold-flat, collapsible podium and a whiteboard with shelving.

-

Fig 1: Finished assembled podium and whiteboard cart

Background[edit | edit source]

Zane Middle and HSU, located in Eureka and Arcata respectively, lie on a six mile stretch of land that straddles Humboldt Bay on the Northern California coast. HSU's engineering department and Zane have been collaborating for several years to enhance student experiences at both institutions by requiring teams of students in Engineering-215:Intro to Design construct and deliver a project to Zane Middle School. Zane's objective was to have several teams create outdoor learning spaces and tools to cultivate creativity and to provide more opportunity for inspiration. One of those teams is the Yerba Mates. The Yerba Mates are Bailey Cochran, Fiona Connor, Daniel Evans and Albert Figueroa. The course is instructed by Lonny Grafman and the team's liaison with Zane was Trevor Hammon.

-

Fig 2: Carving of a falcon, Zane's mascot. Credit: Fiona Connor x2

Problem statement and criteria[edit | edit source]

Zane Middle School wanted a portable outdoor classroom.

-

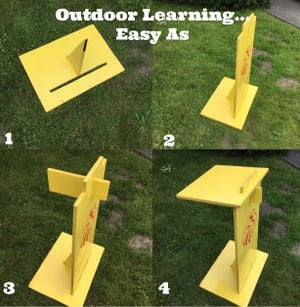

Fig b: Setting up the podium in just four steps.

| Criteria | Constraints |

|---|---|

| Safety | The items constructed should be safe to use for students, teachers, maintenance and any other staff who might interact with them. |

| Cost | The cost of the overall project should not be prohibitive, meaning it should not exceed the $500.00 budget. The cheaper the total cost of the project, the better. |

| Portability | The items must be capable of being moved easily by one person. They must also be able to traverse surfaces ranging from concrete to grass and mud. |

| Durability | All physical aspects of the project must be able to withstand regular use, exposure to the elements, and vandalism. |

| Utility | The items must be functional and must work well by the time the project is presented to the client. |

| Plasticity | The items should be able to be used in different ways, places, and orientations and for different subjects. |

| Aesthetics | The constructed items should appear well crafted and if possible use materials and colors that coordinate with the other half of the classroom as well as Zane Middle School overall. |

| Environmental Justice | The constructed items, as much as is possible, should be made with environmentally friendly materials, be constructed locally, and should not have a negative environmental impact as a finished product. |

Description of final project[edit | edit source]

The final design consisted of a fold-flat podium made of MDP (medium density particleboard) and a second-hand Quartet whiteboard attached to an AV cart donated from Zane Middle School. When the podium is broken down to its constituent pieces it easily fits on the cart making the whole system portable as a single unit.

-

Fig 3: Whiteboard cart with disassembled podium stored on it

Prototyping[edit | edit source]

The project went through several design iterations before the group settled on the final product. Initially the group went through numerous brainstorming sessions to isolate traits of a potential design that met as many criteria as possible. Early designs consisted of podiums on wheels, desks on wheels and a podium with nesting sections that could be stacked atop one another to name a few. In the beginning, the whiteboard was designed to be a cabinet with two doors that opened opposite each other, with the insides of the doors also being of a whiteboard material. The whole cabinet was designed to be made of wood with the whiteboard surfaces either being painted on or pressed on like wallpaper. Prototyping occurred in several phases. Initially, prototyping was done with donated materials from SCRAP Humboldt. Those prototypes included a miniature whiteboard design made of stir sticks and a collapsible podium made of Altoid tins. The next prototype was a collapsible stand made out of some scrap wood. The prototype was made by Albert and was inspired by a collapsible foot stool he had in his house. After perusing podium designs on the internet, the group eventually settled on a design that consisted of interlocking pieces that were held together with gravity and pressure. Yerba Mates immediately set to work on recreating the design with pieces of cardboard. Several pieces of cardboard were glued together to give the model rigidity similar to that of wood. After the success of the cardboard podium the decision was made to go ahead and acquire the materials to begin constructing full scale, final design prototypes. After several mistakes the team learned which cuts to make and how to properly make them. A few additional pieces were added to give the podium added rigidity and stability.

-

Fig a: Portable. Storable. Overall Enjoyable. Teach Outside.

-

Fig 4: Sketch of initial whiteboard design

-

Fig 4a: Collapsible podium prototype

-

Fig 4b: Altoid podium with stir stick white board cart

-

Fig 4c: Stool inspired prototype, open

-

Fig 4d: Stool inspired prototype, closed

-

Fig 4e: Disassembled cardboard prototype

-

Fig 4f: Cardboard prototype, up

-

Fig 4g: Cardboard prototype, down

-

Fig 4h: MDP prototype with body support

-

Fig 4i: MDP prototype with writing surface support

Prototype Testing Results[edit | edit source]

Testing of prototypes yielded several design changes. The prototype based on the folding step stool showed the Yerba Mates that a collapsible or folding podium would not only be too difficult to build but would also likely be too difficult to use on a regular basis. Testing of the MDP prototypes revealed that a writing surface that was angled downward would be more desirable as that was the way the writing surface was inclined to lean due to the force of gravity. Testing of these prototypes also yielded two pieces that were added to the final design. One of those pieces was a triangular piece that holds up the "body" of the podium. The second piece was a semi-rectangular piece that stops the writing surface from slanting to an unusable angle. Lastly, it was decided that a small piece of wood towards the bottom end of the writing surface was necessary to prevent papers, reading materials and writing utensils from falling off of the podium.

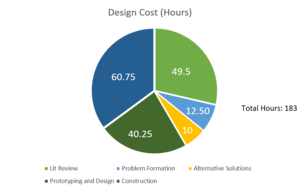

Costs[edit | edit source]

The materials used for the whole design is shown in Table 2. The time (in gender-nonspecific hours) spent on the project is shown in Figure 5.

| Quantity | Material | Location | Full Price ($) |

|---|---|---|---|

| 10 | Medium Density Particle Board | Almquist | 32.00 |

| 5 | Spray Paint | Ace Hardware | 37.22 |

| 3,1 | Masks and Dropcloths | ACE Hardware | 21.95 |

| 4 ea | Screws, Nuts, Washers | ACE Hardware | 15.71 |

| 1 | Velcro Strip | ACE Hardware | 19.97 |

| 2 | L Brackets | ACE Hardware | 9.98 |

| 8 | Magnets | ACE Hardware | 7.28 |

| 1 | Epoxy | ACE Hardwar1 | 7.21 |

| 1 | Rubber Sheet | ACE Hardware | 2.99 |

| 1 | Quartet Whiteboard | Firework | 40.00 |

| 1 | AV Cart | Zane Middle School | Donated |

| Total Cost | $194.31 | ||

Testing Results[edit | edit source]

One person is easily able to move the cart along various terrains with the stored podium. The body of the podium slides in and out of the cart with little effort. The podium is simply assembled and disessembled by one individual. The Whiteboard can be taken off by an adult when needed to combat storage issues.

How to build[edit | edit source]

To build the podium:

Gather two 3' x 3' sheets of MDP. First, cut a piece out using any saw that is 18" wide by 40" long. About a foot from the top, drill a pilot hole and use a jigsaw to cut out a rectangular hole measuring ¾" wide by 5" tall. This will be the body of the podium. Second, cut off two sections from one of the ends of the previous piece that measure 4" long by 2" tall, leaving a rectangle at that end. This is what the writing surface will slide onto. Next, cut a rectangle that measures 24" wide by 20" tall. This will be the base. Into this piece about 1" from the top, drill a pilot hole and then use a jigsaw to cut out a rectangular hole measuring ¾" tall and 18" long. This will be the hole into which the body will be inserted. Perpendicular to that hole, right down the center, cut another rectangular hole measuring ¾" wide by 6" long. This is where you will place the triangular body support.

Next, cut out the body support by cutting out a triangle with a 9" base, a 6" height and a hypotenuse fitting of the Pythagorean Theorem. Then, cut out a rectangle measuring 9" long by 4" tall. This is the most difficult piece to fashion as one end of it must be flat for a few inches and then very gradually taper to an unmeasured angle. This angled portion is what the writing surface will rest on. This rectangular piece must also have a 4" long by 1" tall piece cut out of it to prevent it from slipping out of the hole cut into the body.

Then, cut out another rectangular piece measuring 20" long by 17"tall. About 2" from the top, again drill a pilot hole and use a jigsaw to cut out a rectangular hole ¾" tall by 10" long, leaving 7" on either side of the hole. This will be the writing surface.

Lastly, sand all rough edges to prevent splinters and round all sharp edges to prevent pokes. Paint, finish or decorate however you please.

To build the whiteboard cart:

Use a high tensile, two-part epoxy to attach four magnets to the back, center of the whiteboard. You do not have to place additional magnets on the cart unless you wish to. If your cart is made of ferrous metal you do not need to attach the magnets to the cart with adhesive unless you wish to have the whiteboard placed in a specific place at all times. Next, find where you want the bottom of the whiteboard to be. Yerba Mates positioned the bottom of the whiteboard about 3' off of the ground since the whiteboard they used was just under three feet tall. Once you have determined where the bottom of the whiteboard will be, drill holes in the frame of the cart and use bolts, nuts, and washers to attach one L-bracket to each side. These L-brackets provide extra support for the whiteboard should the magnets prove to not be strong enough to hold the whiteboard.

Next, use and angle grinder or other tool capable of cutting metal to fashion a rectangular hole on one side of the middle shelf that is 18" long and ¾" wide. This hole will hold the body portion of the podium. Creating a clean cut in the metal proved to be difficult for the Yerba Mates with the tools at hand. So, they used pipe cleaner to cover up the jagged edges of the cut to protect both people's hands and the podium body. Pipe cleaners were also used to cover the sides of the L-brackets.

Lastly, paint, finish or decorate however you please.

How to Use[edit | edit source]

Maintenance[edit | edit source]

The few components that make up the design require very little maintenance. The Yerba Mates foresee only needing to oil the wheels on the cart infrequently and possibly touching up the paint. A regular cleaning of the whiteboard with alcohol or sprays made specifically for dry erase boards would prevent the dulling of the sheen on the whiteboards surface.

Troubleshooting[edit | edit source]

Troubleshooting the finished product should be relatively simple. The team foresees the only problems being a broken wheel or a damaged member of the podium or cart. In either case a simple internet search should yield ample potential fixes to the problem.

Suggestions for future changes[edit | edit source]

The Yerba mates had limited tools at their disposal. All cuts were made with a jigsaw. In retrospect, a table saw or handheld circular saw would have been better for the all of the long cuts that were on the side of the boards. Using proper tools for cutting metal would have also yielded a more aesthetically pleasing final product. While MDP was cheap and repurposed it also required an exceptional amount of sanding. Working with a more finished material to begin with would have saved time and made the final product more aesthetically pleasing but would also have increased the cost of the project. The group also welcomes any other suggestions for future changes to this design. An internet full of minds is better than four.

Project Poster[edit | edit source]