Abstract[edit | edit source]

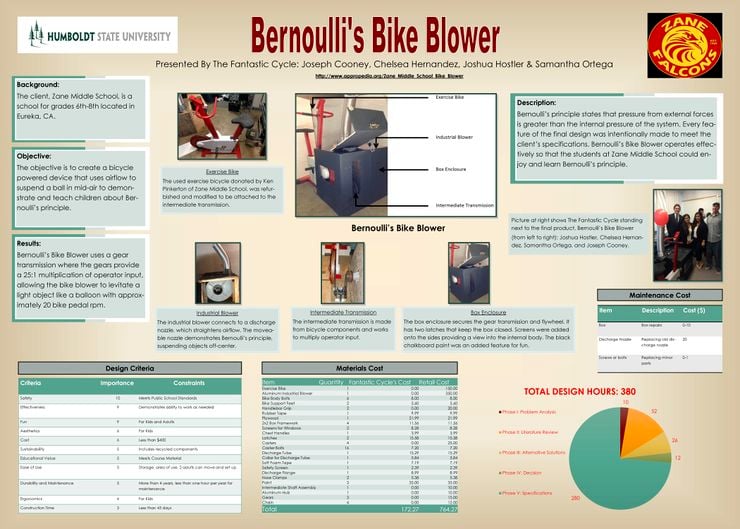

The purpose of this project is to create a bicycle powered fan where students in grades 6-8 at Zane Middle School can generate enough energy to levitate an object. The Fantastic Cycle team set out to make learning fun, and resulted with the device called Bernoulli's Bike Blower. Bernoulli's Bike Blower is an innovative way for the middle school students at Zane Middle School to learn a basic principle of physics. The Bike Blower is set up to generate enough energy to levitate objects in mid air demonstrating Bernoulli's principle.

Background[edit | edit source]

Zane Middle School located in Eureka, California teamed up with Cal Poly Humboldt's Engr205 Introduction to Design class in Spring 2014. The project is aimed at teaching middle school students basic science principles.

Problem statement and criteria[edit | edit source]

The objective is to create a bicycle powered device that uses airflow to suspend a ball mid-air in order to demonstrate and teach children about forces and energy. The following table shows the criteria and constraints:

Criteria and Constraints[edit | edit source]

| Criteria | Importance | Constraint |

|---|---|---|

| Safety | 10 | Meets Public School Standards. |

| Durability and Maintenance | 5 | More than 4 years, less than one hour per year for maintenance. |

| Ergonomics | 4 | For kids. |

| Aesthetics | 6 | For kids. |

| Cost | 6 | Less than $400. |

| Educational Value | 5 | Meets Course Material. |

| Construction Time | 3 | Less than 45 days. |

| Fun | 9 | For kids and adults. |

| Effectiveness | 9 | Demonstrates ability to work as needed. |

| Ease of Use | 5 | Storage, area of use. Two adults can move and set up. |

| Sustainability | 5 | Includes recycled components. |

Description of final project[edit | edit source]

Bernoulli's Bike Blower is an educational hands-on experience for kids to learn about Bernoulli's principle, which states that pressure from external forces is greater than the internal pressure of the system. By enhancing the pedaling of the bike, the device uses a six gear drive system that begins operation by generating power to the flywheel, which connects a chain to a two gear drive mounted on the platform where everything rests, which rotates an intermediate shaft assembly to another gear on the pulley attached to the fan blower. This system causes the fan to spin, thus creating airflow to the designated object.

The final design of Bernoulli's Bike Blower has a wooden box that encloses the fan blower for safety regulations, as well as a wooden box around the gear system. Both boxes include visuals of what's inside to give viewers an idea of how the internal system operates. Both boxes are also painted with black chalkboard paint for the students at Zane to enjoy. Once in use, the airflow generated by pedaling levitates objects provided by the user. The system works and meets the criteria depicted by our client, as well as the criteria laid out by the Fantastic Cycle.

Material Cost[edit | edit source]

The Materials and Cost needed to construct Bernoulli's Bike Blower:

| Quantity | Material | Source | Cost ($) | Team Total ($) | Total Retail Cost($) |

|---|---|---|---|---|---|

| 1 | Exercise Bike | Ken Pinkerton | Donated | 0.00 | 150.00 |

| 1 | Aluminum Industrial Blower | Ken Pinkerton | Donated | 0.00 | 350.00 |

| 1 | Rubber Tape | Ace Hardware | 9.99 | 9.99 | 9.99 |

| 1 | Discharge Tube | Ace Hardware | 15.29 | 15.29 | 15.29 |

| 1 | Discharge Flange | Ace Hardware | 8.99 | 8.99 | 8.99 |

| 1 | Plywood | True Value | 21.99 | 21.99 | 21.99 |

| 2 | Hose Clamps | Ace Hardware | 2.69 | 5.38 | 5.38 |

| 1 | Intermediate Shaft Assembly | Revolution Bicycle | Donated | 0.00 | 10.00 |

| 1 | Aluminum Hub | Marty Reed | Donated | 0.00 | 10.00 |

| 3 | Gears | Revolution Bicycle | Donated | 0.00 | 15.00 |

| 4 | Chain | Joshua Hostler | Donated | 0.00 | 12.00 |

| 2 | Handlebar Grips | Revolution Bicycle | Donated | 0.00 | 20.00 |

| 6 | Bike Body Bolts | Ace Hardware | 1.33 | 8.00 | 8.00 |

| 2 | Latches | Ace Hardware | 7.79 | 15.58 | 15.58 |

| 1 (2 handles per package) | Chest handles | Ace Hardware | 3.99 | 3.99 | 3.99 |

| 4 | Casters(fixed and swivel) | Joseph Cooney | Donated | 0.00 | 25.00 |

| 4 | 2x2 Box Framework (8' length) | True Value Hardware | 2.89 | 11.56 | 11.56 |

| 2 | Bike support feet | Ace Hardware | 2.80 | 5.60 | 5.60 |

| 2 | Screens for Windows | Ace Hardware | 4.14 | 8.28 | 8.28 |

| 16 | Caster Bolts | Ace Hardware | 0.45 | 7.20 | 7.20 |

| 1 | Collar for Discharge Tube | Ace Hardware | 5.84 | 5.84 | 5.84 |

| 1 | Soft Foam Tape | Ace Hardware | 7.19 | 7.19 | 7.19 |

| 1 | Safety Screen | Ace Hardware | 2.39 | 2.39 | 2.39 |

| 3 | Paint | Ace Hardware | 11.67 | 35.00 | 35.00 |

| Total Cost | $172.27 | $764.27 | |||

Labor Cost[edit | edit source]

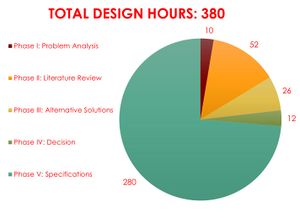

Pie Chart of how many hours the Fantastic Cycle spent on Bernoulli's Bike Blower:

Maintenance Table[edit | edit source]

The following table demonstrates the necessary future maintenance costs:

| Item | Description | Cost ($/year) |

|---|---|---|

| Box | Box repairs | 0.00-10.00 |

| Discharge Nozzle | Replacing old discharge nozzle | 20.00 |

| Screws or Bolts | Replacing minor parts | 0.00-1.00 |

| Total | $21.00 | |

Video[edit | edit source]

How to Assemble Bernoulli's Bike Blower[edit | edit source]

The two main components of recycled exercise bike and box-enclosed blower must be securely connected before use. The front feet on the metal frame of the bike fit into corresponding receptacles on the box to position the bike flywheel in line with the intermediate shaft gear. After the bike is in position, closing the gear drive cover door locks the bike into the blower box.

The exercise bike's flywheel has a permanently installed drive chain that connects to a matching gear on the intermediate shaft. Attachment is accomplished by positioning the bike's flywheel in line with the intermediate shaft gear, and routing the drive chain around both flywheel and intermediate shaft gears. Placing the bicycle frame feet into the locating receptacles on the box properly locates the bicycle and applies tension to the drive chain.

The drive components of Bernoulli's bicycle must be shielded for safety before operation. The blower box has an additional smaller box that covers the drive components and prevents accidental contact with the moving parts. This additional shielding is hinged for bike placement, after which the shield is closed and latched.

The flexible discharge nozzle tube is stored in the gear drive box and must be removed from the box and attached to the blower discharge port prior to use. The discharge port has a metal flange onto which the discharge nozzle is placed. The discharge nozzle is attached to the metal flange with a hose clamp, securing the two pieces together.

Powering Bernoulli's bicycle is similar to pedaling a bicycle, generation of airflow is accomplished by rotating the pedals of the exercise bike to power the blower. The bike and blower box must be on a firm, flat surface and securely attached to each other. When the bike frame feet are in position in the blower box receptacles, the bicycle will be stable and not require balance by the operator. The seat of Bernoulli's bicycle is adjustable for comfortable operation by riders of different heights and leg lengths. After adjusting seat height, the operator sits on the seat and pedals while holding securely to the handlebars. Greater airflow is achieved with faster pedal rotation. When a ball is placed above the discharge nozzle, it will be levitated relative to the amount of airflow. Articulating the discharge nozzle will cause the ball to float "off-center", seemingly defying gravity.

Discussion and next steps[edit | edit source]

Discussion[edit | edit source]

Numerous tests revealed that many of the original design ideas were ineffective. The final design specifications, which are considerably more detailed than the original design, provide solutions to the many problems faced during the development process.

The original design employed a direct friction drive from the flywheel of the exercise bicycle to the pulley of the fan blower. At first there was not enough friction between the two wheels so a layer of rubber was added to the fan pulley to provide a better contact surface. This helped but the fan was still not providing enough airflow. It was also found to be difficult to maintain contact between the flywheel and the pulley. In an attempt to remove the pulley from the fan, so that it could be machined for better contact, part of the pulley broke, shown in the image below.

-

Broken Pulley

At this point, a chain and gear transmission were tested to check its ability to maintain positive contact while simultaneously increasing fan speed. The new transmission, although more detailed and complex, proved to solve several issues present in the direct friction transmission. The chain and gear transmission completely eliminate slipping. In addition, the gears allow an increase in the airflow from the fan to a sufficient level needed to levitate an object.

Next Steps[edit | edit source]

Plans for the future are to try discharge nozzles of different sizes to see how they affect airflow. Also for the future there are plans to experiment with objects other than spheres, such as a paper shapes, or a small kite. Last, equipping the bicycle with a speedometer will allow more identifiable input requirements for different objects.

Authors[edit | edit source]

-

Left to Right: Samantha, Joseph, Chelsea, Joshua