The open-source and DIY OHorizons' Wood Mold allows local organizations to manufacture concrete BioSand Filters for a fraction of the upfront costs of traditional methods, meaning more people can get safe drinking water in their homes faster.

OHorizons' Wood Mold is 10x less expensive than the traditional steel mold method and can be made by anyone, anywhere using basic tools- no experience required! It has been made completely off-grid and by illiterate people using the free-to-download construction manual available at http://www.ohorizons.org/resources/ [1]

What's a BioSand Filter?[edit | edit source]

BioSand Filters (BSFs) use sand, gravel, and natural biological process to filter out contaminants in water, making it safe for drinking. They're a great low-tech drinking water solution that sit in peoples homes. BioSand Filters are a point of use technology. As suggested by the name, this means the water is treated at the point it is used or consumed. This allows users maximum control over the cleanliness of their water and reduces the chances of recontamination.

- No electricity or running parts to operate the filter

- Made with 100% locally available materials (unlike larger community based systems where foreign parts typically need to be imported)

- Labor intensive NOT capital intensive

- Very durable, can last more than 25 years if maintained properly

- Little maintenance required

- Very effective for removing bacteria, protozoa, helminths from water and reducing turbidity

The main problem with concrete BSFs is they require a heavy, expensive steel mold to make. Concrete must be poured into the mold and allowed to cure overnight before the filter body is removed. These steel molds are very expensive and require an experienced welder to make, meaning that many communities or local NGOs do not have the technical capacity or financial resources to start a BSF project.

OHorizons' Wood Mold[edit | edit source]

OHorizons saw an opportunity for innovation in the concrete BioSand Filter manufacturing process. Because the Wood Mold is so cheap and easy to use, anyone, anywhere can bring clean water to their community.

Advantages of the Wood Mold

- Durable (50 filters/mold)

- Cheap ($50-80/mold)

- Lightweight (~ 60 lbs)

- Locally-Sourced Materials (all materials purchased in-country and easily replaced)

- Easy to use (no special skills or previous construction experience required)

- Can be made off-grid

Wood Mold Design[edit | edit source]

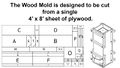

Each Wood Mold is made from a single sheet of plywood and several 2" x 2" support pieces. In the past, other wood molds have been designed in a similar effort to provide an alternative to the steel mold. However, none of these molds have been capable of producing more than 5-10 filters/mold. The OHorizons' Wood Mold can produce approximately 50 filters/mold or more depending on care and the quality of wood used. The design is significantly more durable due to the use of the 2 x 2 supports that hold the outer walls of the Mold together with bolts rather than screws. 5-7 inch bolts are inserted through the support pieces and have a clamp-like effect on the the outer walls of the Mold. Even though the four outer walls are not screwed together, the Mold is tightly held together during a concrete pour due to the bolts. During the de-molding process, you simply have to remove the bolts from the support pieces and the outer walls of the Mold are not affected, meaning they can withstand many concrete pours. If you use screws to hold together the outer walls, during de-molding you must unscrew each of the screws (typically 10-20 on each of the four sides). Removing and then re-inserting the screws into the outer walls of the mold each time a filter is poured greatly deteriorates the strength of the wood over a short period of time. The wood becomes weakened and splits apart, rendering it useless after a few pours.

The patented, collapsible inner core is another reason for OHorizons Mold's superior durability. Other wood mold designers have had problems extracting the inner core during de-molding and have had to break apart the inner mold or even the entire mold in the process. Because the OHorizons Mold's inner core is collapsible, it does not have this problem and it can be reused many times before the strength of the wood becomes compromised.

OHorizons' Construction Manual is free-to-download at http://www.ohorizons.org/resources/ [2]

Project Goals[edit | edit source]

By reducing the financial barriers and by making the Wood Mold Construction Manual open-source and free to download, OHorizons hopes to empower communities around the world to live healthy, productive, and dignified lives through access to safe drinking water.

In the last year, over 150 people and organizations from more than 25 different countries have downloaded the Wood Mold Construction Manual from OHorizons' website. Since 2014, OHorizons has run successful pilot projects in Mali, Ecuador, and Bangladesh. In 2016 alone, 5,000 people in Bangladesh will receive clean water for life through the provision of OHorizons BSFs by the local NGO LEDARS Bangladesh! OHorizons has established an aggressive schedule to provide 1 million people with safe drinking water access by 2021!

- OHorizons In Action

-

The OHorizons Wood Mold

-

Parts of a Concrete BioSand Filter

-

Wood Mold vs Steel Mold Project Cost Comparison

-

The Wood Mold is designed to be cut from a single 4' x 8' sheet of plywood.

-

The Wood Mold being built in Ecuador.

-

Bangladeshi Women stand behind a completed concrete BioSand Filter.

-

A Wood Mold being constructed in Bangladesh.

-

A Wood Mold being constructed in Mali.

-

A OHorizons BioSand Filter in a Bangladeshi Family's home.