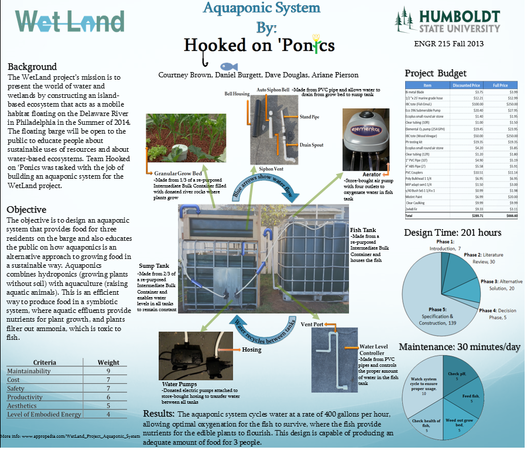

The purpose of this project is to create an aquaponic system that produces food for up to three people who will be living on the WetLand barge in Philidelphia during Summer 2014. It will also provide inspiration to visitors by demonstrating a closed-looped food growing system that can be easily replicated. The project will be a collaborative effort including the WetLand project, residents on the WetLand barge, Cal Poly Humboldt, Team Hooked on 'Ponics, the local community in Arcata, and the community of Philadelphia.

Background[edit | edit source]

-

A rendering completed by Mary Mattingly of the WetLand Project showing the geodesic domes and rough lay out on the floating barges.

-

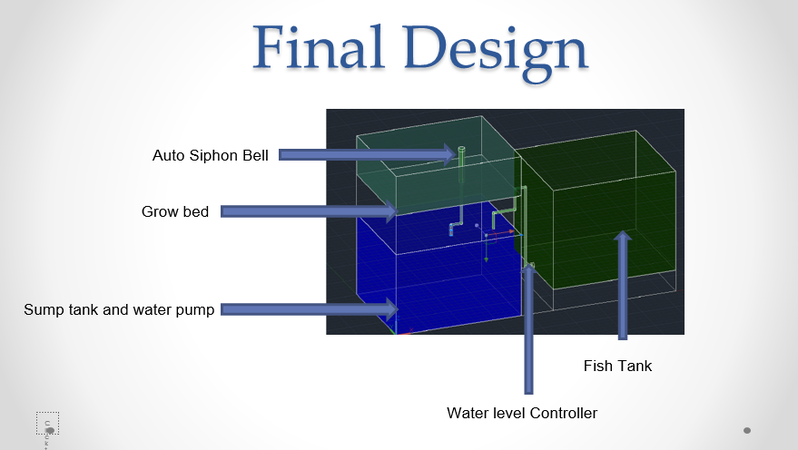

Final design of aquaponic system.

Team Hooked on 'Ponics was started by students at Cal Poly Humboldt in the Engineering 215 - Introduction to Design class taught byLonny Grafman, during the Fall of 2013. The project required the team to construct an aquaponic system for Mary Mattingly's WetLand project. The WetLand project's mission is to present the world of water and wetlands by constructing an island-based ecosystem that acts as a mobile habitat floating on the Delaware River in Philadelphia. The floating barge will be open to the public to educate people about sustainable uses of resources and about water-based ecosystems.

Problem Statement and Criteria[edit | edit source]

The objective of this project is to design an aquaponic system capable of providing food for the occupants of the WetLand Project, while also showing the public a sustainable way to grow food and fish. The aquaponic system will be contained in a greenhouse located on the barge. It will be used by WetLand residents for 3 months in Summer 2014 with minimal maintenance tasks each day to ensure proper functioning of the system. Table-1 (sortable) shows a list of criteria created by the Hooked on 'Ponics team members in collaboration with WetLand team members. These criteria are weighted for importance to help the team choose a design that best fits the client's needs.

| Criteria | Importance | Description |

|---|---|---|

| Maintainability | 9 | Residence on barge must set aside 30 minutes/day to assure system is working properly |

| Cost | 7 | Less than $400 |

| Safety | 7 | Child proof and no one comes into contact with the anaerobic water |

| Productivity | 6 | Produce enough food for three people |

| Aesthetics | 5 | Aesthetically appealing for client and visitors |

| Level of Embodied Energy | 4 | To use as many recyclable and renewable materials |

Description of Final Design: Aquaponic System[edit | edit source]

-

Hooked on 'Ponics final poster design

-

AutoCAD Drawing of Aquaponic System

Aquaponic System Features[edit | edit source]

Tanks[edit | edit source]

The fish tank is made from a used, plastic cube called an intermediate bulk container. The fish tank holds approximately 250 gallons of water with 15 or more fish. The grow bed is made from 1/3 of a used intermediate bulk container and is filled with granular rocks for vegetation to be planted in. The last tank is the sump tank, made from the other 2/3 of an IBC, and holds around 100-200 gallons of water depending on the amount of water that is being cycled throughout the whole system. All tanks are painted with several coatings of mistint to block light.

Pipes and Hosing[edit | edit source]

1 inch PVC piping runs from the fish tank to the sump tank. Water levels are controlled by using hosing for plumbing. Piping also runs from the grow bed to the sump tank. This creates a closed loop system for water and nutrients to be cycled through each tank.

Auto-Siphon[edit | edit source]

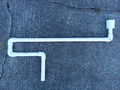

The granular grow bed contains an auto-siphoned bell that drains to the sump tank. The auto-siphon drains water from the grow bed in a cyclical timeframe (not sure exact time yet)

Water Pumps[edit | edit source]

Within the sump tank, there are 2 water pumps that direct the flow of water from the sump tank, to the fish tank and grow bed.

Aerator[edit | edit source]

An aerator hangs outside the sump tank. It uses a hose that goes into the sump tank to increase dissolved oxygen levels in the water, in order for the fish to thrive.

Design[edit | edit source]

The fish tank, sump tank, and grow bed are made from two recycled intermediate bulk containers (IBC). One complete IBC is used for the fish tank and holds up to 1,000 Liters. The second IBC is cut into two sections to form the grow bed and sump tank.

The water level controller passively siphons water from the fish tank to the sump tank. This reduces the energy required the run the system's pumps and ensures that the fish tank will never be drained completely.

From the sump tank, water is pumped into the grow bed where the plants' roots clean the water and the gravel filters out and large particulate matter. After the grow bed is filled completely, the water is drained by the autosiphon and released back into the fish tank where the cycle begins again.

Design Considerations[edit | edit source]

The system was designed to be easy to maintain for people unfamiliar with aquaponic systems. This criteria influenced many aspects of the final design-- most notably, the grow bed. While other parts of an aquaponic system (fish tank and sump tank) are fairy standard, there a variety of options for grow beds. Some of these options required special care and frequent testing and adjusting of water conditions, as well as the installation of additional filters. Ultimately we decided on using a granular grow bed because of simplicity and ease of use. No additional filters are needed, and it requires the least amount human intervention to maintain optimal water conditions.

Energy efficiency was another design priority due to the nature of WetLand. Because the barge would not be connected to the electric grid, all lights, appliances and systems on the barge would only be able to operate on energy generated by the on-board solar panels. This limitation was especially challenging for our system which required air and water to be constantly circulating in the system. With this in mind, we sized our pumps and our system to operate on the smallest wattage possible.

- Components

-

Granular media that hold plants in place

-

Water level controller

-

The autosiphon and drainage pipes

-

Electric water pumps attached to store-bought hosing to transfer water between all tanks

-

An air pump with four outlets to oxygenate water in the fish tank

How To build An aquaponic system[edit | edit source]

Convert your containers into suitable tanks for your system. This step will vary depending on what kind of containers you have procured. Here we are removing unnecessary components from our containers that would have interfered with the operation of the system. It is important to maintain structural stability while simultaneously providing maximum functionality.

Reinforce your system. This step will also vary depending on the specifics of your system. The Hooked on 'Ponics team had to design for their system to be installed on a barge, so they built a frame to hold the grow bed in place. This may not be necessary if your system isn't on a moving barge! Take precautions to ensure that your system is safe and stable in the location that it is to be installed in.

Materials/Costs[edit | edit source]

Materials for the design of the aquaponics system were obtained by buying new, used, and discounted items. Some parts were also donated to the team. Table-2 (sortable) details the total materials and costs for constructing the aquaponics system.

| Quantity | Material | Discounted Price ($) | Full Price ($) |

|---|---|---|---|

| 1 | Bi metal Blade | 3.75 | 3.99 |

| 1 | 1/2" x 25' marine grade hose | 12.21 | 12.99 |

| 1 | IBC tote (Fish Emul.) | 100.00 | 250.00 |

| 1 | Eco 396 Submersible Pump | 20.40 | 27.95 |

| 2 | Ecoplus small round air stone | 5.60 | 7.80 |

| 1 | Clear tubing (10ft) | 1.00 | 1.50 |

| 1 | Elemental O2 Pump (254 GPH) | 19.45 | 23.95 |

| 1 | IBC tote (Wood Vinegar) | 50.00 | 250.00 |

| 1 | pH Testing Kit | 19.35 | 19.35 |

| 1 | Clear tubing (12ft) | 1.20 | 1.80 |

| 10 | 1" PVC Pipe | 4.90 | 5.19 |

| 2 | 4" ABS Pipe | 5.58 | 5.91 |

| 1 | PVC Coupler | 10.51 | 11.14 |

| 1 | Poly Bulkhead 1 1/4 | 6.95 | 6.95 |

| 1 | MIP adapt sxm 1 1/4 | 1.50 | 3.00 |

| 1 | s/40 Bush SxS 1 1/4 x 1 | 0.99 | 1.98 |

| 1 | Mistint Paint | 6.99 | 20.00 |

| 1 | Clear Caulking | 9.99 | 9.99 |

| 1 | 2x4x8 Fir | 9.33 | 3.11 |

| Total Cost | $289.71 | $660.60 | |

Design Cost[edit | edit source]

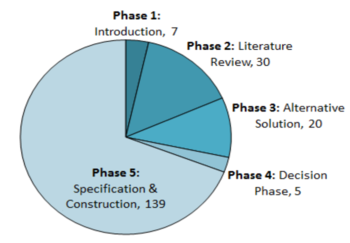

Design cost is measured in hours. The total hours spent on the creation of the Aquaponic System are 201 hours with the total hours being broken down into representative segments shown in the Figure 2 below.

Maintenance Cost[edit | edit source]

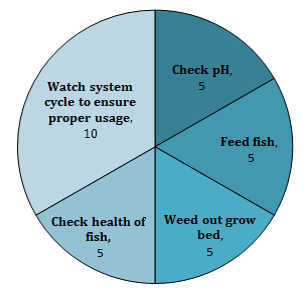

Maintenance cost is measured in minutes per day. The total minutes per day for the Aquaponic System is 30 minutes/day with the total being broken down into segments as shown in the Figure 3 and Table-3 (sortable) below.

| Maintenance | Time (minutes) |

|---|---|

| Check pH | 5 |

| Feed Fish | 5 |

| Weed out Grow Bed | 5 |

| Clean out Dead Fish | 5 |

| Watch System to Ensure Proper Usage | 10 |

Video[edit | edit source]

Results[edit | edit source]

The aquaponic system cycles water at a rate of 400 gallons per hour, allowing optimal oxygenation for the fish to survive, where the fish provide nutrients for the edible plants to flourish. This design is capable of producing an adequate amount of food for 3 people.

References[edit | edit source]

- Aquaponics

- Beneficial Living Center (dedicated to aquaponic systems)

- Instruction Manual & Daily Guide

Hooked on 'Ponics[edit | edit source]

Left to right: Ariane Pierson, Courtney Brown, David Douglas, and Daniel Burgett