Introduction[edit | edit source]

Ellipsometry is a powerful technique whereby the change in the polarization of light reflecting off a surface is analyzed to determine the optical and dielectric properties of a thin film. This analysis can yield information about layers that are thinner than the wavelength of the probing light itself, even down to a single atomic layer. Ellipsometry can probe the complex refractive index or dielectric function tensor, which gives access to fundamental physical parameters and is related to a variety of sample properties including thichkness, morphology, crystal quality, chemical composition, or electrical conductivity.

Unlike single-wavelength (laser) ellipsometry which uses a monochromatic light beam, spectroscopic ellipsometry (SE) employs broad band light sources which cover a certain spectral range in the infrared, visible or ultraviolet spectral region. SE in these regions studies the refractive index in the transparency or below-band-gap region and electronic properties such as band-to-band transitions or excitons. - Wikipedia

Equipment Information[edit | edit source]

The ellipsometer used is a J.A. Woollam Co., Inc vertical-variable angle spectroscopic ellipsometer (V-VASE). The HS-190 monochromator is a Czerny-Turner Scanning Monochromator with a focal length of 160mm. A VB-400 Controle Module contains the power supply and motor drivers. An AutoRetarder is installed but its use is optional for each test. This device improves the analyzer's accuracy by changing the light entering the detector unit from linearly to circularly polarized.

Equipment Specifications[edit | edit source]

V-VASE with AutoRetarder, NIR, DUV, Focusing, Camera, Variable Angle Spectroscopic Ellipsometer with spectral range from 190-1700 nm.

- Vertical sample stage with vacuum stage can accommodate up to 200 mm diameter samples (*call for custom sample mounting*)

- Automated angle of incidence from 20° to 90°.

- Double-chamber monochromator for superior stray-light rejection.

- AutoRetarder- provides highest accuracy on any sample. Also allows for advanced measurements like Depolarization, Anisotropy, and Mueller-Matrix.

- NIR Upgrade – upgrade maximum spectral limit to ~1700nm.

- DUV Upgrade – upgrade minimum spectral limit to ~190nm.

- Focusing Upgrade – removable focusing optics to reduce measurement beam diameter to ~100μm (with included 100μm optical fiber). Focusing optics limit the spectral range below 1700 nm and the angle of incidence to 75° and lower.

- Camera Upgrade – camera with display to view the location of spot on the sample. Actual light beam will not appear on smooth, specular surfaces.

Protocol[edit | edit source]

Turning On (after turning on, wait 20 min before use to allow lamp to warm up)

- Turn on control box first – In Hardware window, click Initialize to sync the computer to the ellipsometer (software key must be in computer to run WVASE32 program)

- Press Light button on monochromator followed by Ignite to turn the light on

- Check to make sure appropriate fibre optic cable is attached – depends on light range/size of beam

- UV: 200nm - 2100nm (dead range from 1350nm – 1450nm due to water absorption)

- IR: 270nm – 2300nm

Turning Off

- Press Light button on monochromator to turn off light, press Light again but not Ignite to leave it off but powered

- If turning entire system off, turn off light, then monochromator, then control module and vacuum

Calibration (to make sure zero is known for the polarizer and analyzer - should be performed at start of every new testing session)

- Insert silicon calibration wafer (apply directly from spider case)

- Click on Align Sample – Calibrate System (default settings are OK)

- Calibration completed once "acquiring calibration data" progress reaches 100%

- Click on File – View Log to compare Ps, As values to previous calibrations

Applying Sample

- Ensure vacuum box is switched on

- Switch to appropriate vacuum port as labelled on the back. Slits and holes are used for large and small samples respectively

- Flip switch on ellipsometer from 'vent' to 'vacuum'

- Use tweezers (pinch tight) through the sample stage groove to apply sample over the vacuum openings

Aligning Sample (performed for every newly placed sample)

- In Hardware window, click Acquire Data – Alignment

- Carefully insert alignment detector

- Align red cross in centre of the four grey boxes on screen by adjusting alignment knobs (two black knobs on back of sample stage) – cross will move around naturally but want it to be close to centre (X and Y values <1 ideally) – press Esc to exit once completed

- If alignment detector is way off (no or very small grey boxes) one must find the beam manually to get rough sample alignment first

- Remove alignment detector

- Align z-axis by adjusting silver knob to maximize the height of the red line on screen (it may gradually rise if the light is recently turned on) – press Esc to exit once completed

Acquiring Data - Spectroscopic Analysis[edit | edit source]

- Calibrate and align sample

- In Hardware window, click Acquire Data – Spectroscopic Scan

- Recommended options:

- 0.025eV - 0.05eV wavelength intervals

- 20 Revs/meas. – greater if noisy

- 3 angles: one below, equal to and above Brewster angle for substrate (53°, 56°, 59° for samples on a glass substrate; 70°, 74°, 78° for samples on a silicon substrate)

- Dynamic Averaging (100 max)

- Save File every 15 min (forces to name file and comment initially)

- More Settings:

- Track Polarizer On

- Auto Retarder if delta is expected to go above 180° (best to have it on)

- Sample Type: Isotropic + depolarization

- Length: Testing one sample will take 35-50 min (if AutoRetarder is used, 3 angles, 0.025eV wavelength intervals, 1 to 4.5eV range)

Acquiring Data - Reflection and Transmission Analysis[edit | edit source]

- Calibrate and align sample

- In Hardware window, click Acquire Data – R+T Data

- Baseline and data scans

- Must move slide stage out of way for baseline scan - do so by pushing base of stage back and wedging a thick object (beige sample holder) in between grey z-axis knob and stage

- Recommended options:

- 0.05 or 0.1eV intervals in wavelength

- 20 Revs/meas. – greater if noisy

- FOR DIRECT TRANSMISSION: set angle from 0 to 0 with a non-zero increment

- Set angles to match spectroscopic scan angles if combining transmission data to with ellipsometry data (eg. for determining material composition)

- Save File every 15 min (forces to name file and comment initially)

- Length: Testing one sample will take about 10-15 minutes

Acquiring Data - Scatterometry Analysis[edit | edit source]

- Calibrate and align sample

- In Hardware window, click Acquire Data – R+T Data

- In Scatterometry:

- Check Scatterometry Enabled

- Sweep Detector (detector moves to pick up scattered light)

- Select area for detector to sweep (ie. -10 to 10 will sweep from 60 to 80 degrees if angle is set to 70) and set interval of measurements

- Baseline and data scans

- Must move slide stage out of way for baseline scan - do so by pushing base of stage back and wedging a thick object (beige sample holder) in between grey z-axis knob and stage

- Recommended options

- Select one reflection angle (0 to 0 by 1 for normal transmission, 60 to 60 by 1 for scattering at 60 deg reflection angle etc)

- 0.1eV intervals in wavelength

- 20 Revs/meas

- Save File every 15 min (forces to name file and comment initially)

- Length: Testing one sample will take about 1-1.5 hrs at one angle sweeping from -10 to 10 by 0.2 with given wavelength range measured by 0.1eV<br

Acquiring Data - Scatterometry Analysis for anisotropic samples[edit | edit source]

- ---

Scatterometry reveals useful information about interaction of light with anisotropic thin films. If samples are optically anisotropic, the angle of incident light and where on the sample the light arrives at matters.

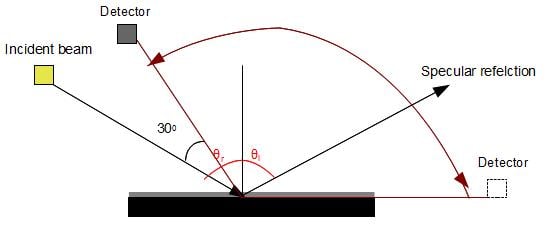

For isotropic samples reflection occurs according to the Snell's law W which means the angle of incident equals the angle of reflection. Therefore, when the ellipsometer is in T/R mode, the detector automatically moves to the position that follows Snell's law. In the case of scatterometry in V-VASE, The detector can be moved azimuthally around the sample stage. This is useful for anisotropic samples that might not follow Snell's law and have reflection/transmission occurs in other angles. By moving the detector azimuthally around, those reflected beams can be detected. For different microstructure different scattering at different angles can happen, therefore, the ideal way is that the detector scan 180 degrees in the plane of incidence. However, since V-VASE is not designed primarily for scatterometry, there are some limitations so that the detector cannot scan 180 degrees in the plane of incidence in azimuthally (reflection mode).

The Figure shows schematically the top view from the position of the detector and the incident beam. The closest the detector and the incident beam can reach is at 30 degrees. Thus, the detector can only scan reflected light for (θi -30o)+ 90o degrees azimuthally. The detector is able to measure specular peaks as well as non-specular peaks within this range (shown as red curve in the Figure). However, any scattering that happens (90o - θi)+30o from the side that detector can't cover, will be missed in the acquired data. For high incident angles a wider range can be scanned by the detector. For example, if the angle of incident is 70o, the detector can scan (70o-30o)+90o=130o degrees and start scanning clockwise away from the incident light. For incident angle of 15 degrees the detector can only moves 75o away from the light source.

Because of this limitation, for different incident angles, one has to set the movement of the detector independently.

Protocol[edit | edit source]

- ---

- Align sample:

In general sample alignment in the V-VASE includes:1- have the incident beam perpendicular to the sample and 2-maximize the beam intensity (follow the procedure in the V-VASE manual). For some of samples that are optically anisotropic, e.g. titled nano-columns thin films, sample alignment involves an extra step.

The procedure stated below is for tilted nano-columns thin film samples:

For this part of alignment, the plane of incident beam (the plane between incident beam and surface normal) should be parallel to the plane of deposition (the plane between surface normal and tilted nano-columns) so that the maximum reflection intensity is obtained. The best way to obtain this alignment is to mount the sample on a stage that has azimuthal rotation about its surface normal. Therefore by rotating the sample in azimuthal direction and observing where maximum scattering intensity occurs, we can find the location that the aforementioned planes overlap.

But the latter alignment requires a rotation stage that V-VASE doesn't own.(under progress by Queen's sustainability group)

A rough solution, If you know approximately the direction that nano columns are oriented, can be to tape samples on a glass slide (in the middle) and place it on the stage as shown in the Figure below. Mark the direction that the columns are tilted towards. The glass slide is fixed with V stage as shown below so it cannot move along the Y axis and it is fixed in X direction. This method can roughly parallel the incident plane and the deposition plane (the vapour direction,shown as an arrow on the Figure, must be perpendicular to the beam light). By moving the slide in X direction or V-stage in Y direction scattering from different points on the sample can be measured.

- In Hardware window, click Acquire Data – R+T Data

- Data type: PR. Refl-P-Pol w/o back side

Repeat the measurement for S-polarized light. To obtain the response for unpolarized light average the result from S and P polarizations.

- In Scatterometry:

- Check Scatterometry Enabled

- Sweep Detector (detector moves to pick up scattered light)

- Select area for detector to sweep (Depending on the angle of incidence the area that the detector can sweep varies as discussed above)

In the software, position of the detector is read relative to the position where the specular peak occurs. For placing the detector as close as possible to the incident beam (which is 30 degrees away from each other),the detector needs to move counter-clockwise and is specified by negative numbers. For commanding the detector to move further than the specular position in the plane of incidence, positive numbers are used. For example if the angle of incident is 60 degrees, the largest area that the detector can sweep is when the detector movement is set between -90 to 30. It means that the detector first is positioned at the specular peak location (0 degrees), then moves 90 degrees counter-clockwise away from its specular position. Thereafter starts sweeping clock wise and passes the specular peak position and goes 30 degrees ahead of it.

| Angle of incidence(o) | Detector sweeping area (Relative angle to the specular peak, degrees) |

|---|---|

| 15 | 0 to 75 |

| 30 | |

| 45 | |

| 60 | |

| 75 | |

| 85 |

- Turn the room lights out and reduce the ambient lightning as much as possible

- Baseline and data scans

- slide the stage out of way for baseline scan - read the position of the stage on the micrometer, move the stage out of the way, when the scan is over bring the stage back to its original position (defined on the micrometer)

- Select angle of incidence

- Select wavelength range between 300nm-1000nm in increments of 100nm

- In change window:

- Check Dynamic Averaging Enabled. "The Dynamic averaging lets WVASE determine the number of analyzer cycles to average by averaging the data until the standard deviation of the noise on the averaged data falls below some cutoff level".

- Set the maximum number of revolution to a number between 1000-2000. Choosing this number depends on how scattering intensity is strong from samples and how much noise exist in the measurement. Try different number of revolution and choose the number that will reduce the noise in your results to a considerable degree, For example in case of tilted nano-columns thin film revolution number of 1000 is acceptable.

- The large number of Max # of Rev will make the experiment time consuming but the data obtained are less noisy,i.e. for detecting a single point, meaning one wavelength, one incident angle it takes 1.25 min for the revolution of 1000. This is useful for observing non-specular peaks that might not be as strong as specular peaks.