I obtained my MSc in Material Science and Engineering from K.N. Tousi university, Tehran Iran. My MSc. research was aimed at Modification of the distribution of nanoparticles ZrO2 reinforced Al composite. After perusing my degree I joined Razi Foundation Metallurgical Lab as a lab expert. Also worker as a welding engineer at Kavosh Joosh Company that is a manufacturer of welding instruments and also building some hard-facing plates for one year, a great experience for a material engineer.

I have been Quality Control Manager, R&D expert and also Technical supervisor in 3D printing of medical implants via SLM and CNC at Bonash Medical Company since 2016. My specialties include material characterization for additive manufacturing technology, metal 3D printing, polymer 3D printing, surface modification, and mechanical properties in additive manufacturing process.

Education[edit | edit source]

- K.N.Toosi University of Technology, Tehran, Iran

- Master of Material Science and Engineering

- Thesis: Modification of the distribution of nanoparticles ZrO2 reinforced Al composite.

- Bu-Ali Sina Univeristy of Tehcnology, Hamedan, Iran

- Bachelor of Material Science and Engineering

- Thesis: An Electrochemical Impedance Study of AlS1321 Stainless steel in 0.5m H2SO4

Research[edit | edit source]

Research Interests[edit | edit source]

- 3D printing of Bio compatible materials

- Material characterization

- Selective Laser Melting Technology

- CNC Technology in producing Ti pedicle screw system in spine

- Surface modification of Ti 3D printed implants

Past Scientific Works[edit | edit source]

- Working on selective laser melting parameters to reduce the cost and energy. This project leads to affordable 3-D printing, and enabling low-cost distributed manufacturing for individuals by studying layer thickness, structural design, internal geometrical shape, the rate of porosities, power of optical lasers, and recoating time in Selective Laser Melting machine for Ti alloys.

- Ti anodizing as a thin coating layer for better biocompatibility. Color coding of Ti parts was the first result in this study. The coloring process involved anodizing, which also affected the corrosion resistance of the alloy. The presence of the anodic film enhanced the corrosion resistance of the alloy. This protective layer is very stable and allows the use of titanium in severe working conditions, such as offshore; in an acid environment; in aerospace and automotive industries; in high-temperature applications; in the chemical and food industries; and in marine hydrometallurgical applications and nuclear fuel waste containment, where no other metal can be used. For example, investigation the duration of the passive and anodizing phase

-

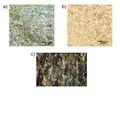

Change in surface appearance of Ti6Al4V 3d printed materials from the different anodiaing process.jpg

-

Fig1. Anodized Ti64 medical implant surface.jpg

-

Fig1. b) Anodized Ti64 medical implant surface.jpg

-

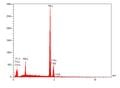

Fig2. EDX analysis of Passive sample with HF+HNO3, Anodizing with H2SO4+HPO3, time-30 s.jpg

-

Fig1.a)3D printed Ti64 (As built).jpg

-

Fig1. b)Sand-blasted titanium surface with biocompatible agent particle sizes 150 μm.jpg

-

Fig1.c)Sand-blasted and Acid etched titanium surface.jpg

Current Projects[edit | edit source]

- Ti anodizing of medical implants for better protein absorption at Bonashmedical Company.

- Mechanical behavior of Ti 3D printed implants and CNC machined in different directions (fatigue test, tensile, roughness,...)

Publications & Conference Presentations[edit | edit source]

- Mina Sadat Mousavi, “Cladding of Rollers of Rollers of Casting Line”, International Conference on Welding and Non distractive Testing, ICWNDT2016

- Hamed Khosravi, Hamed Bakhshi, Mina Sadat Mousavi, “Effects of SiC Particle Content and Stirring Temperature on the Tensile Properties of Al-SiCP Composites Fabricated by Semisolid Stirring Route”, Proceeding of Iran International Aluminum Conference, May 25-26, 2014, Tehran, Iran https://civilica.com/doc/453830/

- Fattah-Alhosseini, M.Mosavi, and A.Allahdadi, “An Electrochemical Impedance Study of AISI 321 Stainless steel in 0.5m H2SO4”, International Journal of Electrochemistry, Volume 2011, Article ID 505929 https://doi.org/10.4061/2011/505929

- (A cooperation with Bonashmedical R&D group) Additive manufacturing of metallic and polymeric load-bearing biomaterials using laser powder bed fusion: A review, Journal of Materials Science & Technology, Volume 94, 20 December 2021, Pages 196-215 https://www.sciencedirect.com/science/article/abs/pii/S1005030221003972

Articles under Review[edit | edit source]

- Mechanical properties and microstructure prediction of friction stir welded Al/Cu T-joint by using hardness map

-

Fig.2 Relationship of macrostructure and microhardness.jpg

-

Fig.3 Microstructure of different zones- a) Al-SZ, b) Cu-SZ, and c) Al-BM.jpg

-

Fig.1. Fixture used for tensile testing..jpg

PROFESSIONAL EXPERIENCE[edit | edit source]

TECHNICAL SUPERVISOR, QC MANAGER[edit | edit source]

- Bonash Medical- http://bonashmedical.com/ Tehran, Iran (2017-Present)

- Remarkable experience with Selective Laser Melting Machine (SLM Solution)

- Excellent knowledge of the structure of Ti 3D printed medical implants

- Profound understanding of structural analysis

- Professional experience in modification process of the osseointegration characteristics of medical implants: SLA process, Anodizing, Coating

- Hands-on experience with chemical examination and mechanical properties of Advanced materials

- Profound understanding of mechanical properties of 3D printed parts

- Trained to work with Fused Deposition Modeling (FDM)

- Cleaning, Sterilization, and Packaging process

- Quality Control Assurance

WELDING ENGINEER[edit | edit source]

- Kavoshjoosh- https://kavoshjoosh.com/ Tehran, Iran (2016-2017)

- Investigated chemical and mechanical characterization of welded parts

- Analytical skill in determination of best material for cladding and hard-facing

- Established Electro-slag welding technique for casting rollers and train’s rails

LABORATORY EXPERT[edit | edit source]

- Razi Foundation (Metallurgy laboratory)- https://www.razi-foundation.com/ Tehran, Iran (2015-2016)

- Practical experience on materials characterization methods including:

- Familiar with analysis methods of metallic alloys (Metallography)

- Mechanical tests of metallic alloys

- Optical Emission Spectrometry

- Chemical analysis

- FE-SEM

- Practical experience on materials characterization methods including:

RESEARCH ASSISTANT[edit | edit source]

- K. N. Toosi University of Technology (Advanced Materials Laboratory) Tehran, Iran (2013-2014)

Teaching Experience[edit | edit source]

Khaneye Mehr School (Work-students NGO) (2012 – 2015)

- Mathematics • Primary-Middle School

- Computer Skill • Primary-Middle School

- Science • Primary-Middle School

- Literature • Primary-High School

Technical Skills[edit | edit source]

- Programming

- Python

- Fortran

- Engineering software

- Tableau

- Catia

- Abacus

- Ansys

- Image-J

- General Skills

- Microsoft office

- Adobe Programs such as PDF Writers, Adobe Photoshop, InDesign

- Windows and Mac OS