Multi-functional platform

The multi-functional platform is a cost effective piece of machinery directed at third world and developing countries, which uses simple renewable energy solutions in order to provide a variety of end-use equipment and greatly reduce the amount of time and energy needed to perform everyday tasks.[1] The project was developed initially for West African countries.

Description of the Platform[edit | edit source]

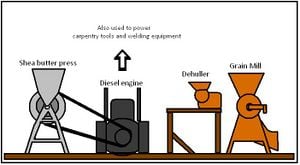

The platform is constructed around a simple diesel engine, which essentially is used to power a number of different mechanical components including, but not limited to, a grain millW, dehuller, pressing machine, and various tools and carpentry equipment. It is built, installed and maintained locally using readily available equipment, thus eliminating the need to spend money on the import of materials from other countries. Another key feature of the platform is its water pumping and electricity generating capabilities. Here you can view an indepth video tour of the multifunctional platform

Benefits[edit | edit source]

The primary benefit of the platform is its simple, inexpensive and efficient nature of supplying the energy needed for the everyday jobs and tasks of a small village. It also is praised for reducing many of the burdensome and arduous tasks of the women of the village such as manual grinding of cereals, traveling to and fetching water and pressing of nuts and seeds for food preparation. Also, because the multicultural platform requires maintenance, as any other machine, to keep it operating, and offers access to a number of different tools, including a weldingW machine and an electric saw, the machine is recognized as a way for those living in the village to become introduced to the development and modernization of many new craftsmanship activities which were once uncommon to them. These include jobs and positions in fields such as carpentry, welding and mechanics.W

Immediate[edit | edit source]

Since the platform is so much more efficient than the traditional methods of working in the village, its implementation is able to increase rest time among those in the village who work to provide food, water and shelter. This increased rest time ultimately means a better average health of the area's inhabitants, as well as more time allotted for physical recuperation throughout the day, or especially at night. It is estimated that in Mali, a nation located in Western Africa, where many multi-functional platforms have been introduced, sleeping time at night is over three hours longer now, which is much appreciated among women whose responsibilities before the platform called for them to fetch water for the village at hours of the morning as early as 3:30 am.[1]

Long-term[edit | edit source]

Along with having the capabilities to solve the immediate problems on the surface, such as those mentioned above, the multifunctional platform can also eradicate the existence of any factors which hinder financial and economic development of the village and its inhabitants past a particular level. The presence of the platform promotes allows for mass production.W Farmers can allocate small plots of farmland for crops and foodstuffs. The multifunctional platform also provides the opportunity for the village inhabitants to earn a greater income through sales of cash crops and food processing made possible by the grain mill and the shea butter press. Another long term benefit which the platform creates once again stems from its ability to perform tasks much quicker than they previously would have been. By freeing young girls from time-costing activities, the platform allows for more women to attend school, as well as training and literacy classes, thereby increasing the level and quality of education in the community.

In many countries in Africa, most rural villages lack any access to electricity. The multifunctional platform boasts the capability to provide a viable electricity source to a small village. It does this using an electric alternator.W The ability to provide a source of electric power is a useful and often novel technology for many small villages in third world nations such as in Africa. This exposure to electric power will offer a village the ability to move ahead into a more technologically developed future, more so than the persons living there were previously used to.

Possible improvements in efficiency[edit | edit source]

For an investment such as the multifunctional platform, it is important to ensure that the innovations brought forward with the implementation of the technology are both cost effective and efficient. Cost-effectiveness is essential because the platform is being designed for use in many underdeveloped areas of the third worldW, where financial stability is scarce.

There are certain adaptations and changes which, if made to the multifunctional platform, would increase its output efficiency, while maintaining its relatively reasonable installation and maintenance costs. These changes involve the choice of materials used for construction, alternative methods of harnessing energy to power the multifunctional platform and alternative methods of storing and using energy.

Materials[edit | edit source]

The platform is constructed using locally available materials in order to avoid costs of importing materials from other countries. This implementation of construction materials local to the specific region is important for saving money, and it is also important in that locally used materials can be called upon again in the event that any component on the platform needs to be repaired or replaced. However, cost plays a primary role in determining how efficient the investment actually is in the long run. The separate components of the platform can be scrutinized in order to determine changes which could be made.

For the grain mill, there are three basic types of grinding mechanisms which can be used to perform the task. These include; plates of iron, steel or stone, spinning metal blades, and thirdly burrs (usually constructed from steel or iron).[2] For many underdeveloped regions, the implementation of stone plates as grinding tools in the mill would be a smart idea, in that stone plates used in mills are made solely from stone, and these plates are similar to those used in older mills which used to be found along rivers. Since the countryside in many African nations is untouched, stones could most likely be plentiful. In using stones as grinding elements, the grain mill would be able to be operated at a lower cost, since a replacement of a defunct grinding mechanism would be simple. Also, stone plates are made to work with dry grains, the most prevalent type of grain processed in underdeveloped African regions as opposed to oily grains, which clog the gradations in the stone, making cleaning more difficult. These stone plate grinding mechanisms, fashioned locally from stones collected right from the earth would greatly reduce costs of having to manipulate metal or steel purchased locally.

Another method of cutting costs would be to decrease the amount of materials which go into the platforms construction. Its design layout is not ideal and has not been optimized to its full potential. Evidence of this is seen, firstly in the spacing between each major component on the platform. As an alternative aimed at optimizing the system, each of the four main components (Shea butter press, diesel engine, dehuller and grain mill) could be constructed on a much simpler base panel using less amounts of metal/steel. It is clear that the base can offer the same support with a less elaborate design of metal rods running parallel to a surrounding metal border frame on which to place the machines. Implementing this new design could also allow for each of the four main components to be unattached, if need be, from the main base platform, in a situation where the grain mill for instance would need to be moved to another area for use.

Alternative energy sources[edit | edit source]

Another possible change to the platform in order to increase efficiency involves the investigation, adaptation and implementation of various forms and sources of energy, other than the diesel engine which the platform is built around.

I-A-I: Investigation, Adaptation and Implementation[edit | edit source]

An I-A-I method describes the necessity for alternative sources of energy to be found in order to replace conventional ones and thus increase efficiency levels while holding steady the quality of performance. The first stage defines the investigation into new methods of harnessing and storing energy which would be applicable to a specific project. In the case of the multifunctional platform, such investigations would be dictated by which type of options available could be supported by a third world community in the long term. The adaptation stage begins when a suitable energy alternative(s) is chosen and involves the methods of introducing this new form of acquiring energy into the platform's operation. The final stage witnesses the actual implementation of the idea into the platform's operation. The success of the new energy option depends largely on whether or not the alternative will hold strong in the long term of using the platform. Also, if the new technology witnesses a rise in efficiency but a decline in quality of product, the new energy source should be rethought.

Pedal Power[edit | edit source]

A suitable alternative form of energy production which could be implemented to replace or work in collaboration with the diesel engine is a bicycle pedal unit which operates on the technology known as pedal power. Pedal power is not a new technology, having been used since the nineteenth century as a means of harnessing energy.[3] Essentially, pedal power is the transfer of energy from a human source through the use of a foot pedal and crank system. The power can be used to power agricultural and hand tools, as well as to generate electricity and store energy for later use. Many third world country projects currently take old bicycles and transform them into pedal powered machines, as a form of sustainable development.[3] The multifunctional platform has not yet employed this technology in its operation. Using bicycle pedals to power the platform will offer a number of benefits.

On the one hand, machines such as the grinder and dehuller, which operate on the basis of a manual hand crank, can be powered much more efficiently and easily using pedal power. This can be done using a device known as a dynapod.,[3] which works through pedal power. A dynapod can be attached to any machine or tool and used to generate power, either power for immediate use or stored power. There have been dynapod prototypes built and used in countries such as Tanzania, where simple square tubing was used to construct the framework. The prototypes, developed by Alex Weir of Edinburgh University were tested as corn grinders and winnowing machines.[3]

Pedal powered devices are much more powerful than hand crank generators, due to their efficiency and variable speed of the output when compared to manually turning the crank by hand. One of the best aspects of the technology is that it requires no fuel, unlike the platform's current energy source, the diesel engine. Pedal power is and can be used to power a multitude of devices including, but not limited to, battery charges, water pumps and off-grid power systems. Essentially any device run by a hand crank or by a fractional horsepower electric motor could be run using pedal power.[3]

Costs[edit | edit source]

The encouragement to increase the efficiency of the platform stems from a number of reasons, the main one being the ability to fund less money into constructing, using and maintaining that is being funded now. As mentioned, the introduction of pedal power would prove to be a viable method of cutting the cost of the main energy constituent; fuel for the diesel engine. To demonstrate the appeal of the pedal power alternative quantitatively, calculations on the energy output of the diesel engine as well as cost, as compared to calculations on the energy output of a dynapod connected to the grinder per say can be performed. The current cost of the multi-functional platform, that includes the equipment and the installation of the basic module is about $4300, with 60% financed by beneficiaries and $2000 subsidized by the project.[1] For calculating the energy produced by the 10 hp engine over a known period of time, the equation below can be used:

E (kW-hours) = P (kW) X t (hrs)

Where: P is the power output of the engine, t is the time in hours, and E is the energy produced. Although there is no concrete answer to the question of how much watts of power can a person put out, due to the fact that everyone is different, it is estimated that an average human being with mediocre physical fitness ability can produce approximately 50 W after pedaling for twenty minutes. This however, will increase depending on the cardio-vascular capabilities of a person as well as their experience riding bikes (controlled breathing). A person with good cardio-vascular ability can output approximately 300 – 500 W per hour.[4] Now assuming a controlled test was performed whereby the engine was set up to run the grinder for a time of twenty minutes (1/3 hours) and a dynapod was set up to run another identical grinder for the same twenty minutes, and assuming all the energy losses occurring were the same for both sources, the following figures can be modeled as an efficiency comparison.

| Power (P) [kW] | Time (t) [hrs] | Energy Output (E) [kWh] | |

|---|---|---|---|

| Diesel Engine | 7.45699872 | 0.333 | 2.483180574 |

| Pedal Power | 0.1 | 0.333 | 0.0333 |

As is expected, the diesel engine is much more capable of producing a much greater amount of energy than the dynapod system. In order to calculate the efficiency of the engine, the brake specific fuel consumptionWcan be calculated. The equation for this is:

BSFC = (Fuel Rate)/(Power)

Where the 'Fuel Rate' is the fuel consumption in grams per hour and the Power is equal to the product of torque (Nm) and engine speed (rpm)

However, this is where the direct reasoning for my choice of this pedal power technology to be implemented comes into play. In order to run the diesel engine, fuel is required, whereas for the dynapod, fuel is not needed. Because I have suggested that pedal power technology be implemented alongside the diesel engine, I think that despite the vast energy output difference, the pedal powered machines can be used in a case where a small amount of cereal grain for instance needs to be grinded for food production on any particular morning. This way, the amount of fuel purchased monthly will decrease and the diesel engine can be run less. There are alos some other important factors to the alternative energy source that must be taken into consideration. It should be realised that the hypothetical test carried out above involved a single diesel engine running against a single human being. However, if for instance ten people were pedaling, in 20 minute shifts whereby another ten people took over, then the process would be more beneficial, although still not as beneficial in terms of energy produced as the diesel engine. Implementation of a system whereby a number of pedal powered dynapod machines were constructed and used for different elements on the platform, then those living in the village can be given jobs to pedal for a certain time shift during the day. This way, not only would the use of the multi-functional platform be fair and balanced (the adults in the community all put work in in order to provide for themselves) but it would also provide each capable person with a specific time frame in which he or she would be responsible for pedaling.

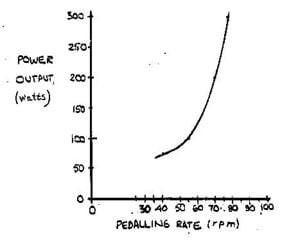

Although the pedal power alternative does not provide as much energy output as the diesel engine, it does in fact provide way more energy than a machine operated by a hand crank. A person is able to generate up to four times more power (1/4 hp) by pedaling than by handcranking.[5] Essentially, what pedal power achieves is the ability to drive devices at the same rate as hand cranking, but with much less effort and a lot less strenuously. In the case of the grinder, pedal power would allow this device to be driven approximately four times faster than a hand crank. As mentioned before, the common output of a pedal powered system, being run by the average person is between 60 and 70 watts. Figure 2 shows how an optimum pedal rate varies with a

desired power output.

References[edit | edit source]

- ↑ 1.0 1.1 1.2 The Multifunctional Platform. "Conception and Development. "[Online] Available www.pfm.net/old/mfpwhat.htm.

- ↑ "Fante's Kichen Wares Shope." Fantes Inc. Available www.fantes.com/grain-mills.html

- ↑ 3.0 3.1 3.2 3.3 3.4 "Pedal Power." Renewable Energy. Available www.alternative-energy-news.info/technology/human-powered/pedal-power/

- ↑ "Pedal Power Generator Frequently Asked Questions." Scienceshareware.com. Available http://scienceshareware.com/bicycle-generator-faq.htm

- ↑ Wilson D. "Understanding Pedal Power." VITA. Available www.cd3wd.com/cd3wd_40/VITA/PEDALPWR/EN/PEDALPWR.HTM

- "Multi-functional Platform in Senegal." Policy Innovations. 2008. Available www.policyinnovations.org/ideas/innovations/data/senegal

- "Multifunctional Platform in Benin." Design that Matters, Inc. 2005. Available www.designthatmatters.org/field-journal/archives/000090.html

- "Corona Grain Mill Dehuller Instructions." Southern Exposure Seed Exchange. Available www.southernexposure.com/grain_and_rice_dehuller.p.html

- Dong A. and R. J. Edberg. "Grain Huller for Rice, Spelt Wheat, Quinoa and Millet." 1989. Available www.savingourseeds.org/pdf/grain_dehuller.pdf

- "Multipurpose Platform Poverty Alleviation." Available www.ptfm.net/old/F-financements%20plates-formes%20GB%20final.pdf

- "Sifter International" – Agro Industrial Food Processing Machinery Plants Equipments Manufacturers Exporters Suppliers, Consultancy Services, Silos. Available at http://www.sifterinternational.com

Contact details[edit | edit source]

This page will be under construction for the next couple weeks, as I will continue to explore the multifunctional platform further and will be periodically updating the content by making additions or other changes (images) to the existing text. I hope that the content which I have provided thus far is of some interest to you. If you notice any errors in my article or can recommend any sources you know of which might have information on the multifunctional platform, you care welcome to leave the information on my discussion page. It would be greatly appreciated. Thanks.