Template:PATBpage Template:Olpc bundle

Introduction

Milling, sometimes also known as fine grinding, pulverising or comminution, is the process of reducing materials to a powder of fine or very fine size. It is distinct from crushing or granulation, which involves size reduction to a rock, pebble or grain size. Milling is used to produce a variety of materials which either have end uses themselves or are raw materials or additives used in the manufacture of other products.

A wide range of mills has been developed for particular applications. Some types of mills can be used to grind a large variety of materials whereas others are used for certain specific grinding requirements. This brief aims to present the factors to consider when choosing a particular grinding applications and to give an overview of the equipment which is available.

Material grinding is quite often an integral part of an industrial process, whether carried out on a large or small scale and in some cases the grinding mill may be the single most costly item for the production operation. Installing a grinding mill which is suitable for the purpose would be one of the main requirements for cost-effective and trouble-free material processing if a grinding stage is involved.

| Abrasives | Petroleum Products |

| Animal products | Pharmaceuticals |

| Brewing industry | Plastics |

| Chemical | Printing ink |

| Confectionery | Rubber |

| Food processing | Textiles |

| Fuel preparation | Sintering |

| Metal power | Refractory materials for investment casting |

| Mineral preparation | Tungsten power and dry lubricants |

| Paint preparation | Dry powder opacifiers for ceramics industry |

| Paper | Carbon black for rubber |

| Pigments for colour industry | Powders for the detergent industry |

| Cement and Limestone | Colour coating of polymers for the plastics industry |

| Grain milling | Aggregates for the construction industry |

| Laboratory milling | Fertilisers |

| Pulverised coal for power generation | Salt |

| Glass, sand, lead oxide, potash and arsenic for glass making | Charcoal for briquetting |

Table 1: Some applications of the milling process

In this brief we will concentrate on mineral grinding, rather than the grinding of grain and other foodstuffs, because a comprehensive publication already exists in the area of grain milling (see final section on resources).

Material Characteristics

When a material is to be milled there are certain characteristics which have to be taken into account. These include the following

• Hardness

• Brittleness

• Toughness

• Abrasiveness

• Stickiness

• Softening and melting temperature

• Structure (e.g. close grained or cellular)

• Specific gravity

• Free moisture content

• Chemical stability

• Homogeneity

• Purity

The hardness of a material is probably the most important characteristic to consider when deciding on what type of mill to choose. Trying to grind a material which is too hard, such as sand in most types of beater mill, will result, either in costly damage to the mill or an expensive maintenance requirement. Most types of readily available hammer mills for agricultural grinding are not suitable for grinding most types of minerals.

Hardness of minerals is expressed on Mohs scale - a numerical index ranging from 1 for talc (the softest mineral) to 10 for diamond (the hardest known material). Table 2 below shows Mohs’ scale of hardness.

| Hardness No. | Mineral (example) | Common practical test |

| 1 | Talc or graphite | Marks paper - like a pencil |

| 2 | Rock salt or gypsum | |

| 3 | Calcite | Can be marked with fingernail |

| 4 | Fluorspar | Can mark a copper coin |

| 5 | Apatite | |

| 6 | Felspar | Can mark window glass |

| 7 | Quartz | Can mark a knife blade |

| 8 | Topaz | |

| 9 | Sapphire | |

| 10 | Diamond |

Table 2: Mohs’ scale of hardness

In general, the harder the material, the more specialised and expensive the type of mill used has to be. In addition if a particular mill can be used over a range of hardness scales, the harder the material the lower the throughput for a given size requirement. Another characteristic of a material to be aware of is brittleness, which is the degree to which a material will easily break. Most minerals are brittle, as opposed to metals which are ductile, although some to a greater degree than others. Brittleness does not equate with hardness as brittle materials can be hard or not particularly hard. Materials which are not brittle to some degree, metals or soft plastics for example, cannot easily be milled.

Free moisture content of a material should be as low as possible for dry milling. In practice this can be a problem, especially in humid regions where the moisture can cause the material to stick to the grinding media. Different mills behave in different ways with moist materials and in some cases drying of the raw materials be required.

Also important is the final size of the material in question. Table 3 below gives details of some materials which are milled and the degree of fineness required. Specifiers may stipulate that a proportion of the material is finer than a particular size. Usually this is 90 or 95% but may be 99% for particularly demanding application. In certain applications a particular range of particle sizes is required.

| Material and Application | Particle Size in mm |

| Feldspar - (flux in ceramics) | 0.075 |

| Talc - (paper making and cosmetics) | 0.01 |

| Limestone - (agricultural lime) | 1.2 |

| Ordinary Portland Cement | < 0.10 |

| Chalk | 0.05 |

| Powdered charcoal or coal for fuel briquettes | <0.10 |

| Pigments for Paints (various materials) | ~ 0.005 |

| Silica quartz (glass making) | 0.01 |

| Phosphate (fertiliser) | 0.075 |

| Iron Ore | 0.20 |

| Lime (industrial applications such as detergents) | 0.10 |

| China clay | 0.002 |

| Alumina | 0.005 |

Table 3: Material Particle Size

Characteristics of Mills

Types of mills

In this brief we categorise mills in 3 groups:

- Low-speed tumbling mills

- Roller mills

- Very fine grinding mills, which include the following types of mill:

• High speed pulveriser or hammer mill

• The vibrating mill

• Pin mill

• Turbo mill

• Fluid energy mill

• Stirred media mill

There is also a section which looks at traditional mills used in developing countries and other forms of size reduction other than milling:

• Attrition mills e.g. stone milling

• Cutting machines

• Cryogenic comminution

Glossary for the milling process

Milling circuit - open and closed. The milling circuit is the complete mill system from beginning to end, including feed mechanism, mill, classifier, separator, product collector, etc. In a closed mill circuit the oversize particles are returned from the post milling processes to be remilled (see figure below) whereas with an open circuit the process has no feedback loop.

Air classification. Classification or sizing of particles using a mechanical air separator.

Batch mills. Mills which receive a discrete quantity of charge which is milled and then discharged. The process is then repeated.

Continuous mills. A mill which can accept a continuous flow of feedstock and hence can operate on a continuous basis. Both batch and continuous mills have their relative merits.

Peripheral and trunnion discharge. For cylindrical mills which are continuously fed, the discharge of the final product can be either through the periphery of the mill (peripheral discharge) or through the far end of the mill (trunnion discharge).

In this section we will now look in more detail at the mill types mentioned above.

Tumbling Mills

Autogenous mills

Description

This type of mill consists of a large diameter, short length cylinder fitted with lifting bars. The cylinder is fed with a coarse feedstock of up to 250mm in size and in rotating the feedstock is lifted and then allowed to drop through a significant height. Three significant mechanisms cause the breakdown of the mineral; impact due to the fall of the mineral onto the charge below causes a reduction in the size of the feedstock; attrition of smaller particles between larger grinding bodies; abrasion or rubbing off of particles from the larger bodies. Steel or ceramic balls are often added to aid with the reduction process (the mill is then referred to as

a semi-autogenous mill). The process can be carried out wet or dry. Removal of the final product can be carried out using air (where the process is dry) removing only the fines. Rotational speed is usually fairly low, about 80% of critical speed (critical speed is the speed at which the charge will be pinned to the rotating drum and does not drop) and typical drum diameter ranges from 2 to 10 metres. This type of mill is often used as a single stage process, providing sufficient size reduction in a single process. Alternatively, it can be part of a two stage process where further size reduction is required.

Characteristics

This type of mill is only suited to certain kinds of mineral - one which has a fairly coarse nature but once it is broken will disintegrate readily into a small size. In certain circumstances this type of mill can deliver a product with a fineness of less than 0.1mm. Testing is required beforehand

to determine the suitability of a mineral for processing in an autogenous mill.

Suitable minerals such as copper or iron ore are listed in table 4. This type of mill has the distinct advantage of accepting coarse feedstock and supplying a relatively fine finished product, often sufficient as an end product. This can provide a reduction in plant costs if a single mill is used as a substitute for two or more stages. There is little wear as the grinding is often carried out by the mineral itself. Autogenous mills are most suited to large installations i.e. more than 50 tonnes per hour and have a power requirement ranging from 40 kW up to hundreds of kW.

| Iron ore | Phosphate |

| Limestone | Bauxite |

| Copper ore | Slags |

| Uranium | Niobium ores |

Table 4: Material Suitability for Autogenous Mills

Rod Mills

Description

The rod mill is another tumbling mill but having a large percentage of its volume (30 - 40%) loaded with steel rods. The rods are placed axially in the mill and are loose and free to move within the mill. The internal lining of the drum has a series of lifters which raise the rods and drop them at a predetermined point. The mineral is fed in at one end with a maximum size of about 25mm. The rods crush the rock and as the charge passes through the mill it is reduced in size to approximately 2mm to 0.1mm.. The mill can be fed from one end with the product removed from the other end or, alternatively, the mill can be fed from both ends with the

discharge at the centre. The process can be wet or dry but is more commonly carried out wet. Maximum rod length is about 6 to 7 metres, otherwise there is a risk of the rods bowing. The drum diameter is limited to 0.6 or 0.7 times the length of the mill.

Characteristics

Rod mills are used for grinding hard minerals. This type of mill is usually used as the first stage of a milling process to provide a reduced size feedstock for a further milling process.

| Coke | Products for the glass industry |

| Cement clinker (needs to be dry) |

Table 5: Material Suitability for Rod Mills

Ball Mills

Description

Ball mills are similar in concept to the rod mill but are charged with steel balls in place of the rods. The mill consists of a cylindrical drum, sometimes tapered at one end, and usually has a charge of steel balls (up to 40% by volume) ranging in size up to 125mm for larger mills. Product size can be as small as 0.005mm, but product size is dependant upon the time the charge spends in the grinding zone and therefore the reduction rate is a function of the throughput. The lining material is of great importance as there is a significant amount of wear taking place due to the action of the steel balls. The speed of rotation is optimum at about 75% of critical speed. Some mills are compartmentalised with each subsequent section having a smaller ball size. The mineral can pass through to the proceeding section, but the balls cannot. This ensures that the smaller particles are attacked by the smaller grinding media.

Characteristics

It is a versatile grinding mill and has a wide range of applications. The mill can vary in size from small batch mills up to mills with outputs of hundreds of tonnes per hour. They are the most widely used of all mills. Small hand operated ball mills are used in Bolivia for preparation of ore, sand and gravel.

| Iron ore | Coal for combustion |

| Limestone | Talc |

| Cement | Sand |

| Gold ore |

Table 6: Material Suitability for Ball Mills

Roller Mills

Description

There are two distinct type of roller mill. The first is a series of rollers which rotate around a central axis within a drum. The reduction takes place between the rollers and the drum. The second is where there are a series of fixed rollers and a rotating table. The milling takes place between the rollers and the table. This type of mill is used for dry grinding only and accepts only relatively soft minerals. Small machines can have a throughput of only a few tens of kg per hour whereas larger machines are capable of handling up to 40 or 50 tons per hour and occasionally more. Feed size varies according to the machine. The machines are often fitted with screens for closed-circuit grinding. Product size can be controlled by changing screens.

| Barite | Phosphate |

| Limestone | Coal |

| Slate | Miscellaneous Chemicals |

Table 7: Material Suitability for Roller Mills

Very fine grinding mills

Hammer mills

Description

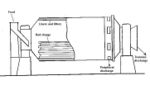

These are high-speed mills operating at speeds of between 2000 and 6000 rpm A set of ‘hammers’ rotate about a central axis in a vertical or horizontal plane. The hammers can either be fixed or can swing freely, in which case the mill is termed a swing-hammer mill (see figure below). The whole system is enclosed in a housing and the outlet for the product is usually via a

screen which sieves the product and allows only the required size of particle to pass.

Characteristics

The product size can be extremely fine - talc can be reduced to a size of 0.0025mm (40%), although an air classifier is required when such product size is required. Maximum capacity is in the order of 10 tons per hour and power consumption is relatively high. Rotating hammer mills are suited to the milling of sifter materials and this type of mill is often used to mill grain and other food stuffs.

| Calcite | Talc |

| Barite | Grain and other food stuffs |

Table 8: Material suitability for hammer mills

Pin, air classifying and turbo mills

Description

A pin mill comprises two discs, one rotating and one stationary which are fitted with intermeshing pins set in a concentric pattern. The charge is fed into the centre of the discs and is broken down as it moves outwards through the pins which are moving at very high speed - up to 20,000 rpm

The air classifying mill is similar in construction to the pin mill but incorporates a built-in classifier. This type of mill produces a significant airflow through the machine to aid with keeping temperature as low as possible. Oversize grains which pass through the mill have to be recycled. Turbo mills use a similar concept but the rotating disc is fitted with paddles or bars rather than pins. This rotating disc sits within a cage which is fitted with grids, screens or breaker plates. The mill is configured in such a way as to produce the desired particle size.

Characteristics

Pin mills are capable of very fine grinding without the need for screens and provide a uniform product size. Air classifying mills are used where the product is temperature sensitive. They are widely used in the pharmaceutical and fine chemical industries. They are suitable for relatively soft materials (below Moh 3) and for small quantities of material. Wear on the pins is significant if used continuously.

| Carbon | Pharmaceuticals |

| Chalk | Spices |

| Talc | Sugar |

| Pigments | Resins |

| Dyestuffs |

Table 9: Material suitability for pin, air classifying and turbo mills

Vibratory mills

Description

This is the first mill we will consider which does not rely on rotation for the main grinding action. The vibrating mill is a grinding chamber which is filled to about 65 - 80% of its capacity with grinding media such as balls or rods. The chamber is vibrated at a frequency of between 1000 and 1500 times per minute (can be variable speed) by cams or imbalanced weights. The grinding action is efficient and thorough. Grinding media material and chamber lining can vary depending on application.

Characteristics

Vibrating mills can grind hard or soft materials. Maximum throughput is in the order of 20 t.p.h. but feed size should be kept fairly small. Although final product size can be as low as 0.005mm this type of mill is often used for less fine applications. Product size and shape is a function of the

time spent in the mill, media type and size, and frequency of vibration. Commonly functions as a batch mill.

| Lime | Calcium carbide | Alumina |

| Gyspsum | Bauxite | Chromite |

| Limestone | Sillimanite | Fluorite |

| Pigments | Dolomite | Magnesite |

Table 10: Material suitability for vibratory mills

Stirred media mills

Description

Stirred media mills are usually constructed in the form of a cylindrical drum inside which there are a series of rods, arms or perforated discs which are rotated on a central shaft. The drum is loaded with grinding media, such as metal balls or glass sand. The media and the charge is ‘stirred’ together and thus the grinding takes place.

Characteristics

Suited primarily to the very fine grinding of soft materials. Usually used with wet grinding but can be used for dry grinding also. Product size is as small as 0.005mm.

| Pigments | Kaolin |

| Colorants |

Table 11: Material suitability for stirred media mills

Fluid energy mills

Description

The general principle of operation in a fluid energy mill is that the mineral to be ground is fed into a grinding chamber in a high speed, high pressure and, often, high temperature jet of air (or other gas). The particles collide violently and this causes comminution to take place. Various designs of fluid energy mill exist, the most common being the microniser. This mill has a shallow circular grinding chamber and a series of peripheral jets set tangentially to a common circle. The turbulence causes bombardment which effects a rapid reduction in particle size. A centrifugal classification system keeps larger particles within the chamber while allowing fine particles to leave. In a well designed fluid energy mill there will be almost no contact between the charge and the mill lining.

Characteristics

Suitable for hard or soft materials to be reduces to 0.02mm or less. This method of milling tends to be energy intensive and slow but is suitable where the product is highly sensitive to heat or contamination from grinding media.