These instructions describe how to make your own loam plaster professionally, with a group of people.

1. Preparation[edit | edit source]

1.1 Machines and equipment[edit | edit source]

1.1.1 General information[edit | edit source]

The right tools/machines make work easier, faster and safer. When purchasing tools and machines, do not simply buy the cheapest ones, as they are usually not at all suitable for our projects, are imprecise and break quickly. This can quickly lead to frustration - and it can also quickly become dangerous. For our purpose, we need robust machines that also work well over a long period of time. For you, this means that the machines need e.g. to be oiled and maintained regularly. Well maintained, such machines can last a lifetime, i.e. they can be of service to you long after the house has been built.

It is advisable to create a central location where unused tools can be stored and retrieved. If a tool is broken, this should be reported to the person responsible for the machine at the next opportunity.

1.1.2 Basic Tools List[edit | edit source]

Note: The number of materials and tools required depends on the size of the project.

To get an idea, Column # shows the recommended number of tools needed for a group of 5. Minimum is always 1.

| # | Name | Comment |

|---|---|---|

| 1 | Shovel | |

| 2 | Hoe | To mix and move the Loam Mix |

| 1 | Sponge | |

| 1 | Hammer | if you have the choice: its best to buy one with hooves to remove nails |

| 3 | Metal Trowel | Classic one handed version |

| 3 | Dipper | To scoop the material from e.g. the bucket to the trowel |

| 5 | Very stable bucket | The Buckets are in heavy use - thin buckets wont last long |

| 3 | Ruler or Tape-Measure | e.g. rulers that can be folded and stored in the pants |

| 1 | Ladder | Choose one that is stable and most important: has the right height. |

| 1 | Broom | A solid one, to keep the area clean and prevent people falling over things. or slip out in wet straw. |

| 5 | Work Gloves | Woven work gloves with a protective plastic are a good choice. wear it especially, when working with heavy tools to avoid blisters, to have a better grip or as a protection against scarves etc. |

| 1 | First Aid Kit | Including in particular disinfection solution (alcohol), bandages, leukoplast tape and wound healing ointment |

1.1.3. Material needed for a sieve[edit | edit source]

see e.g. https://www.youtube.com/watch?v=mQPC1ZNGMUM how to build a solid one

| # | Name | Comment |

|---|---|---|

| x | Wooden Slats for outdoor use | |

| 1 | Wood saw, manual or electronic | Pay attention to the right blade: some are for stone, some for wood etc. |

| x | Screws (no slotted screws) | If there is no other way, use nails and hammers |

| 1 | Electric Screwdriver |

1.1.4 Optional but recommended[edit | edit source]

| # | Name | Comment |

|---|---|---|

| 1 | Duct Tape | General Purpose Tool, its super strong and durable. |

| x | Cover material | Sheets and normal tape |

| 3 | Cutter knifes | General Purpose Tool |

| 1 | Rake | To spread the mixtures, choose a very solid one not the one with the fine metal |

| x | Tarps | If you don't want the substrate to mix with the clay (e.g. if only one grass pitch is available). you can look out for old banners from events |

| 1 | Plasterer Metal Ruler | This Metal Ruler is often more than 1 Meter long, and used to level out the wall. some have teeths, to scrape off overlapping material. It is often not needed, but when the walls have to be straight then its a must. you can see the tool in the following video: https://www.youtube.com/watch?v=LDnalPbK3bk |

| 2 | Large trowel | to work faster and to make the surfaces more flat over a large area |

| 2 | Small spatula | for finer parts and work |

| 2 | Sturdy cloth bags | for transporting e.g. gravel or straw, that is filled in bags. even heavy stones can be transported in bags, much easyer. |

| 1 | Mixing Machines | Electric Mixing Machines. Can also be used for pre-mixing. From Handy Tools up to bigger construction mix machines |

| 2 | Light source (e.g. halogen construction lights 400W and more) | Always good to have, not only when it gets dark but also for rooms that are dark in the morning/evening. |

| 1 | Jukebox/Speakers | |

| 1 | Power Generator | Its not cheap but to have a strong source electricity is often needed for machines etc.. Calculate in, that power generators can make problems from time to time. |

| x | Medicine such as anti-allergy drugs for straw work | |

| x | Sturdy, waterproof gloves | Only when working with paint, for example |

| 1 | Blackboard with chalk, including magnets and sponge | its optional but highly recommended |

1.2 Time considerations[edit | edit source]

As clay only dries slowly (1 mm per day), sufficient time should be allowed. It should also be noted that rainy periods, for example, can massively increase the drying time. Our materials not only have a long drying time, but can also freeze. As soon as the temperature falls below 0 degrees Celsius at night, you should no longer work outside. The same applies, of course, if it is not possible to heat indoors.

2. Loam Tests[edit | edit source]

The quality and suitability of Loam for plastering can vary greatly depending on the location. It is therefore worth scouting out several locations for sampling. As a general rule, the loam for loam-samples, like clay in general, should always be taken at least 30 cm below the surface. The soil on the surface, known as topsoil, contains too many organic components (roots, grass, humus, etc.) and is therefore unsuitable. Clay can often be obtained cheaply or even free of charge without much effort when excavating for a house, for example.

2.1 Jar test[edit | edit source]

Fill the jar half full with a sample. Then fill up the rest with water and shake well for approx. 1 minute. Then leave to stand for at least 1 day so that the individual components settle. This test gives us an approximate idea of the composition. Example: jar filled to 5 cm with clay mix, of which 2.5 cm is clay = 50 per cent clay content.

2.2 Smell/odour and taste test[edit | edit source]

A simple smell test is one way of determining whether a loam contains a lot of humus. A high humus content should be avoided whenever possible. A taste test is necessary for the salt test, which is particularly recommended for locations close to the sea. If the loam is salty, it is unsuitable.

3. Sieving[edit | edit source]

Loam often contains large stones and impurities we don't want. Leaving these in would mean constantly removing them during work, which is annoying. We use a sieve to remove these impurities, allowing us to make both coarse and fine plaster.

3.1 Basic organization when sieving[edit | edit source]

It often and quickly happens that it is no longer clear what has already been sieved and what has not. Or mixtures get mixed up, there are piles of unclear mixtures etc.. This is particularly unfortunate because a lot of time is always spent on sieving. Accordingly, neither the filtered material nor the valuable working time should be wasted because of such things. The pile-system must be clear to every worker. Nobody should start somewhere, transport the filtered material somewhere or make a pile somewhere.

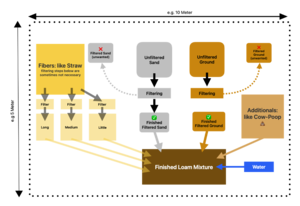

Below is an example of a possible workplace organization. The example also shows well how many substances are involved (and should not be mixed). But it also shows that we are dealing with more than just a few work steps. A visual example like this also makes it easier to explain to workers - especially if there are language difficulties. The system should not be changed by individuals without having a talk with the team.

3.2. The Sieve[edit | edit source]

The parameter size of the sieze can be chosen freely, but should not be too fine. The finer the sieve, the exponentially longer it takes to filter the materials. As the time required can be enormous, it is worth buying several mesh sizes or sieves and trying them out. If you find that the time required is too high, the sand can alternatively be purchased from a gravel works so that at least this no longer needs to be sieved.

Overview of the mesh sizes of the sieve

- Clay slurry/glue: 0.5 cm

- Base coat: 1 cm and larger

- Top coat: 0.7 cm

A stainless steel screen is recommended. The strainer should be screwed down securely as it is subject to high loads. Expect, that the sieve will have to be repaired after a certain time.

All materials should be as dry as possible before sieving. If you notice during test sieving that it is not going well, the material must be spread out on the ground and dried - in a place that is permanently protected from rain and, at best, wind. The materials should not be stored directly on grass or other organic surfaces. Where only grass is available, the top layer must be removed (10 cm, preferably 30 cm). Otherwise, this unwanted grass soil, the root system and seeds, for example, can find their way into the mixture. If you have one, you can also use a robust tarpaulin and then the substrate is no longer so important.

Glossary:

Clay: binder

Loam: mixture between clay and sand

Soil/Earth: general Term for Material from the Ground, including topsoil, ground soil etc.