- Sheet metal is often available as scrap from car wrecks, roof sheets, and the better parts of rusted-through oil drums.

- There is much local experience working with sheet metal.

- The setup of many designs can be based on the use of sheet metal, as its special application can be derived from what is already general known.

How?[edit | edit source]

- Sheet metal can be cut and bent without expensive machines; a hammer along with simple hand tools such as a machete, knife, or axe will do the job.

- Sheet metal, especially very thin tin, can be cut by scoring the metal with a sharp metal point, and then bending back and forth to fatigue the metal. When bent a few times along this scored line, the metal will separate very accurately.

- Thicker sheet metal, from 1.5 mm to 3 mm, can be cut using a hammer and a sharp chisel to cut a groove with into the sheet metal surface on an anvil. On turning the sheet over, the marks of the cut can be seen, and a second groove is then cut with the chisel. Again, bend back and forth along the scored lines until the pieces separate.

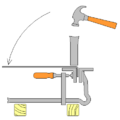

- For still thicker metal plate, you will need more force than you can apply using bare hands. You can get the extra force using leverage. Simply attach one or more levers to the metal plate, and arrange them at right angles to the scored line, but not crossing the line. The levers may be timber or metal, whatever is available, and they can be reused for other projects. The levers can be attached with wire, screws, clamps, rope, whatever you have, as long as you can easily remove the levers from the cut metal plate.

Freeing Sheet Metal From a Drum[edit | edit source]

The smart trick is to drive the sharp point of an axe along a line marked on some piece of sheet metal. Only the sharp point has to cut through. Don't let the blade sink deeper into the cut, as this spoils the work. The line can be straight, make curves or make sharp angles. It only takes a little practice to follow the line with the sharp front end of the cutting edge. Fast but light hammer strokes on the flat side of the axe forces the cutting. The edge of the cut sheet bends inwards. This can be flattened, by folding it over some more, then flattening the double layer; this makes the edge stiffer, smooth, and safe for handling. A drum has strong edges made to shape the connection between the bottom and cylinder. Make good use of this reinforcement by cutting close to the edge. Cutting with the axe is easier when the sheet metal does not bend away from the cutting. But cutting free-suspending sheet metal is also easily possible by driving the axe with more horizontal hammer blows and at the same time inserting the tip of the axe at a sharper angle to the surface of the sheet metal.

Flattening Sheet Metal[edit | edit source]

When a 200-liter oil drum is used to harvest the sheet metal, the cylindrical-shaped metal has to be flattened. This works well by pounding it with a log as shown in the picture. Start in the middle and then work towards the ends.

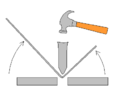

Folding Sheet Metal[edit | edit source]

Folding sheet metal is easy. You can use almost the same method as with cutting. Hammer the axe along, but prevent making a cut, only make a linear sharp dent in the sheet. Bend over the part that has to be folded. Sometimes it helps to fold over an edge, but with some practice just applying some force with hammer blows does the job. This method of folding yields an accurate fold exactly at the line that is dented with the axe.

- For example, sheet metal is used for making Weld wood.

How to Make a Tight Bend[edit | edit source]

The method illustrated in Step 1 will only work well for short lengths of thin sheet metal. For longer lengths, the angles will need to be longer and will need to be clamped together at the ends - use a couple of G-clamps. For thicker sheet metal, apply force by hand to the top of the piece, then use a hammer as per Step 4.