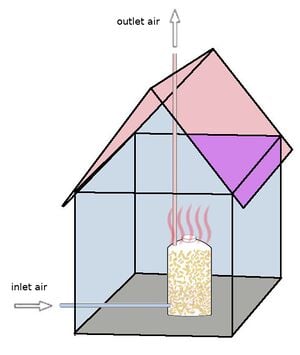

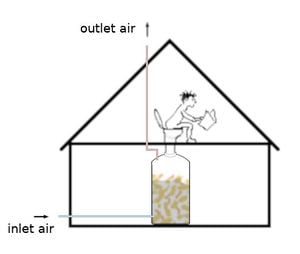

The compost heater silo is the central part of an inhouse compost heater. The composting process is run in an airtight silo, placed in an appropriate part of the building. The produced heat can be distributed by a heating circuit, whereas a simple model of such a compost heater silo does not require a water circulation, radiating the heat directly to the interiors of the house. In autumn the silo is filled up with fresh biomass, after which the silo delivers comfortable heat all winter long.

Construction[edit | edit source]

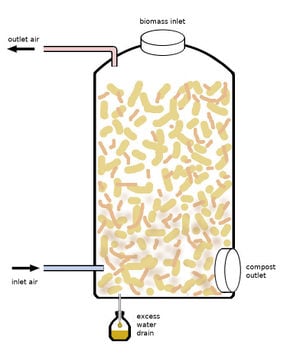

Inlet air and outlet air provide the necessary oxygen supply for the microbes and invertebrates in the silo. To avoid a bad smell, the outlet air must go out to the open, and it must be protected against incoming animals (mice).

The moisture in the silo must be high enough to support the composting process, providing optimal conditions for microbes and fungi. After successful start the decay process produces additional water, which is drained at the bottom of the silo. This water can be put in to the top of the silo for better distribution of the microbes in the whole processing volume. If pumped periodically or continuously to the top and let it rinse through the silo the whole system becomes similar to the wet composting (C.R.O.P. Project of the DLR[1][2]).

Optionally, the composting process in the silo can be used to heat up water, which requires the additional installation of a vertical water pipe in the silo, maybe in combination with a hot water storage tank.

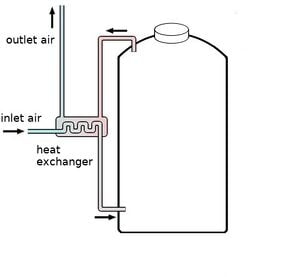

Pre-Heating of the Inlet Air[edit | edit source]

The outlet air is leaking part of the heat. There are a few solutions to reduce this:

- An optional heat exchanger can be built in, which withdraws heat from the outlet air and increases the incoming air temperature.

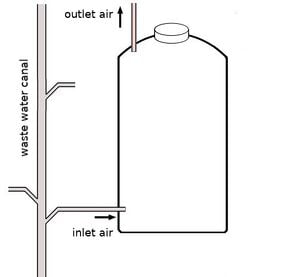

- Connecting the air inlet to a waste water canal. The construction utilizes the venting of the canal while adequately prevents influx of waste water into the silo. Usually, there is warm air rising from a waste water canal. Although foul-smelling the air contains enough oxygen for the well-being of the microbes and invertebrates.

Conditions of Usage[edit | edit source]

The amount of produced heat is limited. The size of the compost heater silo must be adapted to the actual heat energy demands of the building. For example, the House-in-a-House concept is suitable for it due to the very low heating requirements. For calculations refer to the respective paragraph in compost heater.

Existing Systems[edit | edit source]

Prototype of size 300 liter for a feasibility study. It serves for research on the features and their optimization. The system has been working since September 2017 and is doing very well.

Planned Extensions[edit | edit source]

-

Double layer wall for venting hot air to other rooms. Excess heat can be dissipated from the building.

-

Distribution of the heat using regular heat circuits

-

With hot water storage inside the silo

-

Version with a single air pipe

Concret and Tiles[edit | edit source]

The final setup for heating a dwelling house will be made from thin layered concrete, encased with tiles. It will resemble a tiled stove.

Double-Walled[edit | edit source]

The silo will be double-walled, which allows better channeling of the warm air. If less heat is wanted, say on a warm spring day, the excess heat can be lead away into the open.

Water Heating[edit | edit source]

A heat storage tank for warm water will be placed in the center of the silo. The tank absorbs thermal energy from the surrounding decay process. The warm water can be used for domestic usage. The best performance is achieved if constructed as layered or stratified charge storage.

Combination with a Toilet Function[edit | edit source]

The compost heater silo can be expanded to an integrated compost heater toilet system. The system serves as a heater and a toilet at the same time. The silo is filled with waste biomass (chipped wood, etc.), which is the basis of the wet decay process. Additional biomass (feces and urine) can be added. The decay process breaks down the excreta before it can reach the bottom of the silo, so it works as a small biological clarification plant.

The combination of a compost heater silo with a toilet function provides a number of advantages:

- No water flushing system is required. This saves a lot of fresh water.

- No connection to a public sewage canal is required, because this is a standalone system.

- The resulting inorganic matter (water, CO2) does not polute the environment. The outlet water contains valuable minerals and can be directly used as liquid fertilizer for the garden.

- The additional biomass adds to the heat energy for the house warming.

- If build correctly, the slight vacuum from the ventilation pipes prevents any smell in the house, which is better than any other toilet system.

For convenience the toilet input is located on the upstairs floor, where the regular biomass inlet is combined with a toilet seat. In contrast to a dry toilet the excreta are processed in a wet environment and therefore are much faster decomposed.

Version with a single pipe[edit | edit source]

In rented apartments, you usually can't just make a large hole through the roof or the outer wall. Therefore, it will be described here how a compost heating silo can be realized without an inlet air pipe. It is sufficient to connect the system to the sewage network. The supply air is taken directly from the room air via a blower, i.e. the blower pushes room air into the silo. The exhaust air escapes through the sewage pipe. A check valve prevents air flow in the wrong direction during times when the blower is not running.

With this arrangement, small systems for the kitchen can be realized, in which mainly organic kitchen waste is rotten. With suitable dimensioning the structure fits under the worktop.

Safety Considerations[edit | edit source]

Fire Protection[edit | edit source]

The emerging heat can result in an unwanted spontaneous combustion. Biological decomposing can increase the temperature beyond 60 degrees Celsius, when pure chemical processes set in to drive the temperature up to a dangerous level. This can happen especially if wet grass is filled in. The condition depends on moisture and oxygen concentration.

The extreme heat is an unwanted effect, which can result in the destruction of the silo. Also, the building around the silo can be at danger. Therefore, precautions are to be taken to reduce the implications of a fire.

- Selection of fire-proof construction material for silo and pipes (e.g. Concrete, Steel)

- Installation of an automated fire extinguishing system. This can be a simple water container on top of the silo, that pours its content into the silo when a heat triggered safety valve opens.

Emergency Opening[edit | edit source]

If an infant or a living pet accidentally falls through the inlet into the silo, the danger of suffocation arises. The construction must allow an emergency opening in this case. A rescuer must be able to enter the silo immediately. This can be achieved by a removable lid and a permanently available ladder, for example.