Abstract[edit | edit source]

The portable stage was built for our client Zane Middle School to allow their students to become more involved in performance arts while making sure they learn in a fun, positive way. Zane Middle School does not have a theater and their previous portable stage was not big enough to accommodate for enough students. Our group, The Train Conductors, were given the opportunity to design and construct a 8'x16' and 8" tall portable and store-able stage for Zane Middle School. Our team designed the stage to be of a simple construction for the community members to recreate and/or maintain the stage as needed. A description of the stage, list of materials, and instructions to build can be found below.

Background[edit | edit source]

During the Spring 2018 semester, engineering 215 students at Humboldt State partnered with Zane Middle School to complete several design projects for the students and faculty. Our client Zane is a S.T.E.A.M. oriented school, meaning they predominantly focus on Science, Technology, Engineering, Arts, and Mathematics. The school puts focus on the sciences as well as the arts to give the students a more rounded education. Zane's drama and social science teacher, Zach Lehner, uses a small stage to allow students to have a more entertaining and productive learning experience. Currently, Zane Middle School does not have a designated theater to carry out their performances. Zane Middle Schools wishes to expand their theater arts through the construction of a new stage.

-

The four stage sections stacked on top of one another.

Problem Statement and Criteria[edit | edit source]

Zane Middle School's drama students lacked a place to perform and were being deprived the experience of a having an elevated platform to increase the experience in stage presence.

Criteria[edit | edit source]

| Criteria | Weight | Constraints |

|---|---|---|

| Safety | 10 | Must be safe for use by middle school students. |

| Durability and Longevity | 8 | Must be weather and damage resistant and withstand prolonged usage. |

| Total Cost | 8 | Budget of $225. |

| Weight Capacity | 7 | Must hold the weight of 5-10 students (approximately 500-1000 lbs). |

| Portability | 5 | Must be easily transported by middle school students and easy to store. |

Prototyping[edit | edit source]

-

AutoCAD design shows the dimensions of the stage as it would be used within the classroom.

-

An angled view of the stage on AutoCAD demonstrating the final design.

-

Testing the portability by use of skateboard trucks to help move the stage.

-

A group member demonstrating how one could use a stage during the production of a prototype.

Description of final project[edit | edit source]

The stage that we decided to produce was constructed out of 2"x 8" douglas fir boards and ¾" construction grade, sub-floor plywood sheeting. The frame of the stage was made of the 2"x 8" boards held together with torque screws. The frame was built in four sections that each measure 4'x8'. The sections will each be topped with a sheet of plywood that measures 4'x8'. The plywood will be fastened to the frame with torque screws. The stage is made of four units, making it a total of 8'x16' and 8" tall. The purpose of having built the stage in four standalone sections is that it makes the stage much easier to move and allows the users to reorganize the stage into different configurations. The stage is covered in black high-grade exterior paint so that it will not distract from the performers.

- DIMENSIONS - Four sections each measuring 4' x 8' x 8" (16'x8' total)

- FRAME - 2" x 8" Douglas Fir Boards

- TOP - ¾" Subfloor Plywood

- PAINT - Black Latex Based Polyurethane Fortified Floor Paint

- HANDHOLDS - 6" Rounded Holds

- DOLLIES/PORTABILITY - Furniture Dollies Rated 1000 lbs.

-

The finished product of the stage.

Costs[edit | edit source]

This section lays out the total costs of the projects. It will cover the design costs as well as the time spent to formulate the design and construct this project.

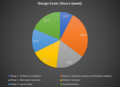

Design Time Costs (Hours):

The design costs represent the amount of time The Train Conductors spent (in hours) within each phase of the design project.

-

Design cost in hours representing the time spent on the project.

Implementation Costs ($):

The costs of materials are listed below:

86 linear feet of 2"x 8" Boards: $110.94. (10 linear feet donated by Pierson Building Center.)

1 ¾" subfloor plywood sheet (4'x8'): $41.99. (3 sheets donated by Pierson Building Center.)

2 1000 lbs. rated furniture dollies: $23.84.

1 gallon Acrylic based polyurethane floor paint: $31.99.

1 case Torque Screws donated by Jim Mclaughlin Landscaping.

Total Cost $229.82 + donations

The table below represents the estimated retail cost of the project.

| Material | Quantity | Source | Retail Cost ($) | Cost with Donations($) |

|---|---|---|---|---|

| Case of torque Screws | 1 | Jim McLaughlin Landscaping | 23.48 | Donated |

| 2" x 8" x 8' Boards | 96 ln ft | Pierson Building Center | 123.84 | 110.94 |

| 3/4" Plywood Sheets (4'x 8') | 4 | Pierson Building Center | 167.96 | 41.99 |

| Furniture Dollies | 2 | Harbor Freight | 23.84 | 23.84 |

| Black Paint (200sqft) | 1 | Ace Hardware | 31.99 | 31.99 |

| Paint Tray | 1 | Pierson Building Center | 2.59 | 2.59 |

| Taxes | 1 | 27.84 | 15.68 | |

| Total | $397.95 | $229.82 | ||

Results[edit | edit source]

Students to become more engaged in performance art activities at Zane Middle School thanks to the implementation of the stage.

-

Our client representative, Zach Lehner, testing out the portable stage.

-

The students at Zane Middle School acting during class on the new stage.

-

-

Prototyping vs. final design.

Maintenance[edit | edit source]

The cost to maintain the stage is very minimal, as it only requires the user to touch up the paint if it should get chipped or scratched. Many issues that could occur with the stage will likely be simple to fix with sanding, new screws, or wood glue. Maintenance costs should be below $10 a year, with some years requiring more maintenance.

Instructions[edit | edit source]

Before using the stage, the user must first set the stage up. The four pieces must first be un-stacked from the the corner of the room and put together on the floor. The easiest way to move the stage is to use the hand-holds that are attached at either end of the 4' sides on each stage component. There are no locking mechanisms on the stage pieces to hold the separate pieces together, so there is no need to be very specific where each piece goes as long as they are all placed together.

Furniture dollies are used to move the stage over a distance. The user must put the furniture dollies as under the center of the 8' side of a stage section. The user must then flip the stage with this 8' section face down on the dolly.

Maintenance Schedule[edit | edit source]

- Annually

- Sand any spots on the stage that have taken excessive wear or abuse. If any sharp corners or edges have become noticeable, knock the sharp edges down by sanding. The floor paint will eventually begin to fade due to abrasive wear, so certain areas will need to be repainted to cover these spots.

Suggestions for future changes[edit | edit source]

- The addition of wheels to the 8' foot side of the stage sections would help make it even more portable.

- The addition of a skirt around the outside of the stage that can detach and reattach would improve the aesthetics of the stage.

- The addition of locking mechanism connecting all four sections of the stage would add more stability.

- The addition of grip on the bottom of the stage sections would allow the stage to stay in place due to the friction.

References[edit | edit source]

- California Code of Regulations, Title 8, Section 3231. Stairways. (https://www.dir.ca.gov/title8/3231.html)

- California Code of Regulations, Title 8, Section 1626. Stairwells and Stairs. (https://www.dir.ca.gov/title8/1626.html)

- Coyote Steel (2018) (http://www.coyotesteel.com/assets/img/PDFs/weightspercubicfoot.pdf)

- Engineering Toolbox (2018) (https://www.engineeringtoolbox.com/wood-density-d_40.html)

- Demolition Forum (2018) (http://demolitionforum.com/material-weights/)

- Lexington Container Company (2018) (www.lexingtoncontainercompany.com/Milk-Crates-Dairy-Crates.html)