The Solar Swing is a project from Cal Poly Humboldt's Engineering 215 class. The Solar Swing is a solar oven designed to be implemented in elementary schools across the United States to give children confidence while they learn about solar technology and practice cooking skills.

Background[edit | edit source]

Locally Delicious is a group of ladies from Humboldt County, California who promote the local foods movement and strive to move away from industrial agriculture. They have helped to fund many local projects such as Food for People, which selects six local farmers to grow specific food for food banks, the Mobile Processing Unit for the Poultry Cooperative, and the Potawot Garden in Arcata.

The group gets their name from their first book, which aims to provide recipes and resources for residents of the North Coast. They are currently working on their second book - Lunchbox Envy. The book is targeted towards parents, older children and their mentors. The goal is to create healthy lunches that kids will want to eat and includes projects that kids can do by themselves, with adults, or at their school.

Locally Delicious contracted our team to design and implement a solar oven in Trinidad School to be used as an example for a do-it-yourself project to be included in Lunchbox Envy.

Project Definition[edit | edit source]

This project is a solar oven that can be replicated at elementary schools across the United States by adults with the possible help of the students. It must meet the client's criteria.

Project Criteria[edit | edit source]

The project criteria and constraints were considered by the both Operation S.O.S. and the client. The criteria were then weighted in order to determine the strengths and weaknesses of the Alternative Solutions.

Table 1: Project Criteria, Descriptions and Weights.

| Criteria | Description | Weight |

|---|---|---|

| Oven Safety | The oven must be safe for elementary school children and meet the school's insurance policy. | 10 |

| Durability | The oven must last for three to five years. | 9 |

| Efficiency | The oven must thoroughly cook the food prepared by the Junior Chefs within their designated meeting times. | 9 |

| Portability | The oven must be easily moved around the Trinidad School campus and fit into their storage space. | 8 |

| Cost | Each team member contributes up to $75 and the client contributes up to $75, so the final cost cannot exceed $375. | 7 |

| Ease of Use | The oven must be operable by the Junior Chefs, grades four through six. | 7 |

| Effectiveness -teaching | The oven must meet the Common Core Content Standards for English and Mathematics selected by the California Academic Content Standards Commission (http://www.scoe.net/castandards/). | 6 |

Cost[edit | edit source]

Design Hours[edit | edit source]

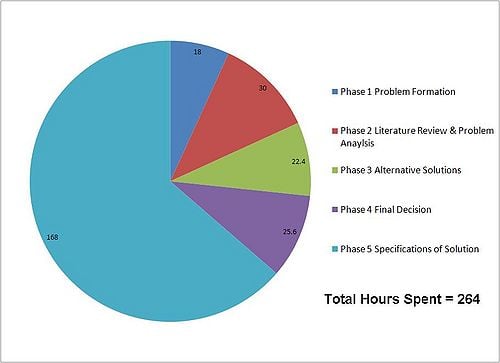

The following chart includes how much time was spent in each section of the design process.

Building and Materials Costs[edit | edit source]

Table 2 includes the current retail value of the materials used as well as the cost that our team was able to produce it at.

Table 2: Material Costs

| Quantity | Material | Source | Our Cost($) | Retail Cost ($) |

|---|---|---|---|---|

| 1 | Mylar Roll | Ace Hardware | 18.52 | 18.52 |

| 4 | Corrugated Plastic Sheets | Ellis Art & Engnrng | 21.39 | 23.76 |

| 1 | Full-sized baking sheet | Angels of Hope Thrift Store | 3.75 | 17.99 |

| 1 | Tube of silicone adhesive | Pierson's | 2.32 | 2.58 |

| 1 | 4'x8'x1.5" Rmax foam sheet | Pierson's | 27.24 | 30.27 |

| 2 | L-shaped aluminum connectors | Ace Hardware | 3.50 | 7.08 |

| 1 | Bottle heat resistant black paint | Ace Hardware | 7.62 | 7.62 |

| 1 | Roll of aluminum foil | Ace Hardware | 3.26 | 3.26 |

| 1 | Oven thermometer | Ace Hardware | 8.71 | 8.71 |

| 1 | Tube of caulk | Ace Hardware | 7.62 | 7.62 |

| 1 | 1/4" drill bit | Ace Hardware | 6.09 | 6.09 |

| 2 | Bead corner drywall 8' | Ace Hardware | 6.08 | 6.08 |

| 2 | Aluminum rivets 100 packs | Ace Hardware | 5.24 | 5.24 |

| 8 | Flange bolts | Ace Hardware | 4.80 | 4.80 |

| 8 | Flange nuts | Ace Hardware | 4.40 | 4.40 |

| 8 | Flange lock washers | Ace Hardware | 1.04 | 1.04 |

| 8 | Flange flat washers | Ace Hardware | 0.96 | 0.96 |

| 2 | Floor flange 1/2" galvanized | Ace Hardware | 13.06 | 13.06 |

| 2 | Wire rope clip | Ace Hardware | 6.52 | 6.52 |

| 1 | 3/4" wooden dowel | Ace Hardware | 3.80 | 3.80 |

| 2.6 | foot of chain | Ace Hardware | 7.07 | 7.07 |

| 4 | large S-hooks | Ace Hardware | 6.08 | 6.08 |

| 2 | Stainless steel hinges | Ace Hardware | 23.96 | 23.96 |

| 6 | Hinge bolts | Ace Hardware | 2.94 | 2.94 |

| 6 | Hinge nuts | Ace Hardware | 1.50 | 1.50 |

| 9 | foot of stove gasket (large) | Ace Hardware | 17.55 | 17.55 |

| 4 | foot of stove gasket (small) | Ace Hardware | 4.32 | 4.32 |

| 9 | Plastic bolts | Ace Hardware | 5.40 | 5.40 |

| 1 | metal file cabinet | Scrap yard | 0.00 | 60.00 |

| 1 | Range oven bottom | Scrap yard | 0.00 | 55.00 |

| 2 | Drip edge, galvanized | Ace Hardware | 8.26 | 8.26 |

| 1 | Roll of nylon twine | Ace Hardware | 4.68 | 4.68 |

| 1 | Pane of tempered glass 29.5"x23.75" | Eureka Glass | 35.70 | 35.70 |

| 1 | Tube of epoxy glue | Ace Hardware | 4.68 | 4.68 |

| 1 | Roll of metal repair tape | Ace Hardware | 5.87 | 5.87 |

| 1 | Roll of Heavy Duty Reynolds Wrap | ERE Department | Donated | 3.00 |

| Totals | $286.95 | $425.42 | ||

Maintenance Costs[edit | edit source]

The following two tables describe the annual operation and maintenance costs associated with The Solar Swing. Table 3 shows current retail values of possible replacement materials. Table 4 shows the annual labor involved in maintaining The Solar Swing.

Table 3:Annual Material Costs

| Material | QTY | Annual Materials Cost |

|---|---|---|

| 25'x48" Mylar Roll | One roll | 18.52 |

| Silicone | 1 tube | 2.58 |

| Reynolds Wrap | 1 roll | 3.00 |

| Total | $24.10 | |

Table 4:Annual Labor Costs

| Task | Time Spent (hrs/year) |

|---|---|

| Cleaning of Oven | 13 |

| Replacing Mylar and Reynolds Wrap | 2 |

| Total | 15 |

Final Design[edit | edit source]

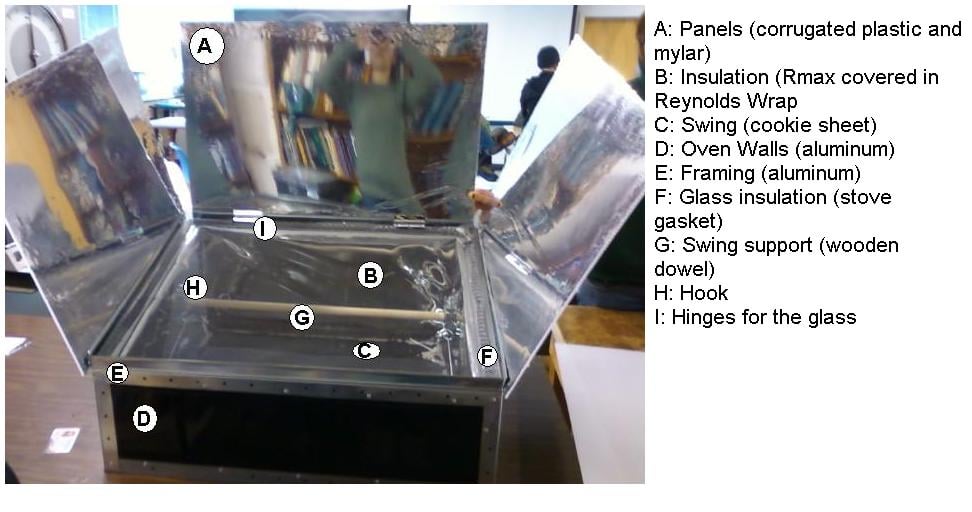

The Solar Swing is a box-shaped oven that has one wall that is taller than the rest, creating a top face that is slanted downwards. A pane of tempered glass is used as the glazing on the top face of the oven. The window serves as the oven's door by swinging open from the top. The oven has three fold-out, removable, reflective panels that are held onto the box by aluminum framing and plastic bolts. The outside box is made from sheet metal, and the insulating material in the interior is 1 ½" Rmax foam board. On the interior faces of the oven, placed in-front of the Rmax, is heavy duty Reynolds Wrap wrapped and stapled around corrugated cardboard. Inside the oven is a swing that is suspended from a wooden dowel. It is on this swing that the baking container or surface is set. As the oven is propped at different angles, the swing allows the cooking surface to remain parallel to the ground.

Building and Implementation Instructions[edit | edit source]

Complete instructions on how to build and operate The Solar Swing can be found here.

Results[edit | edit source]

Table 5: Testing Results

| Test Run # | Date | Location | Time of Day | 0 min (deg F) | 15 min (deg F) | 30 min (deg F) | 60 min (deg F) | 90 min (deg F) | 120 min (deg F) | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 4/19/11 | HSU Campus | 2:30 PM | below 100 | 140 | 190 | 250 | NA | NA | |

| 2 | 4/22/11 | Trinidad School | 3:30 PM | below 100 | 155 | 210 | 255 | 245 | 245 | |

| 3 | 4/24/11 | Sunny Brae | Noon | below 100 | 140 | 205 | 245 | 275 | 260 |

Discussion[edit | edit source]

The Solar Swing fits the criteria required for this project. It is safe for elementary school children, it is expected to last for at least five years, it reaches temperatures that can bake a batch of cookies within one hour, it is lite enough to be easily moved by two people, it is within budget, it is easy to use, and it has many educational elements. The temperatures reached and maintained are higher than the team expected would occur. When baking a batch of cookies as a test, the cooking time was approximately 50 minutes, whereas the bake time in a 350 degree oven was 20 minutes. Although The Solar Swing was built and tested in Arcata, California, the varying weather conditions across the United States were considered. The materials used are meant to last in a wide range of temperatures and should not be too difficult to locate in different locales. Also, the potential to change the angle of the glazing on the box and the concept of propping the oven up along its back edge allows for the capture of more direct sunlight at different elevation angles of the sun.

Next Step[edit | edit source]

With the solar oven complete our next step will be to take it to Trinidad School and have the Junior Chefs use it and give us feed back so we may make any minor alterations they might have.

References[edit | edit source]

Average Temperature (2008). "Eureka Average Temperature." Average Temperature, <http://www.average-temperature.com/temps/CA/Eureka> (Feb. 20, 2011)

Center for Science, Mathematics, and Engineering Education. (1996). "National Science Education Standards." National Academies Press, Washington D.C.

Dormio, Dane, and Steven Jones. "Who Uses or Could Use Solar Cookers." Solar Cookers International. BYU Physics Department, 15 Aug. 2002. Web. 21 Feb. 2011. <http://web.archive.org/web/20190913102002/http://solarcooking.org:80/research/Dormio-report.htm>.

Fitzpatrick, Richard. "Spherical Mirrors." Home Page for Richard Fitzpatrick. 14 July 2007. Web. 21 Feb. 2011. <http://farside.ph.utexas.edu/teaching/316/lectures/node136.html>.

Franco, Judith, Carlos Cadena, and Luis Saravia. "Multiple Use Communal Solar Cookers." Solar Energy 77.2 (2004): 217-23. Science Direct. Web. 20 Feb. 2011.

Funk, P.A, and D.L Larson. "Parametric Model of Solar Cooker Performance." Solar Energy 62.1 (1998): 63-68. Science Direct. Web. 20 Feb. 2011.

Halacy, Beth, D. S. Halacy, and Beth Halacy. Cooking with the Sun. La Fayette, CA: Morning Sun, 1992. Print.

Jones, Steven E., Colter Paulson, Jason Chesley, Jacob Fugal, Derek Hullinger, Jamie Winterton, Jeannette Lawler, Seth Jones, David Jones, Nathan Jones, and Dannelle Jones. "How to Make and Use the Solar Funnel Cooker." Solar Cookers International. Web. 21 Feb. 2011. <http://web.archive.org/web/20201114003414/http://www.solarcooking.org/plans/funnel.htm>.

Ligtenberg, Allart. Solar Cookers International. Rep. Web. 21 Feb. 2011. <http://web.archive.org/web/20161204062301/http://solarcooking.org/Ligt-report1.htm>.

Nahle, Nasif (2009). "Heat Transfer, Conduction, Convection and Radiation." Biology Cabinet Organization, <http://www.biocab.org/Heat_Transfer.html> (Feb. 19, 2011)

Peters, Joseph M. and David L. Stout. (2006). "Methods for Teaching Elementary School Science." Pearson Education, Inc., Upper Saddle River, New Jersey.

Pidwirny, M. (2006). "Earth-Sun Relationships and Insolation". Fundamentals of Physical Geography, 2nd Edition. <http://www.physicalgeography.net/fundamentals/6i.html> (Feb. 20, 2011)

Schwarzer, Klemens, and Maria Eugênia Vieira Da Silva. "Characterisation and Design Methods of Solar Cookers." Solar Energy 82.2 (2008): 175-63. Science Direct. Web. 20 Feb. 2011.

Solar Circle. (2010). "How Solar Ovens Work." More About Solar Ovens, <http://solar-circle.org/index.php?page=how-solar-ovens-work> (Feb. 20, 2011).