Banana beer is made from bananas with grain flour (often sorghum flour) and is fermented into an orange alcoholic beverage. It's sweet and a bit hazy with a shelf life of several days under the right storage conditions. You can make the beer in different ways. For example, in Kenya, Urwaga banana beer is made from bananas and sorghum or millet, and Lubisi is made from bananas and sorghum.

Green material preparation

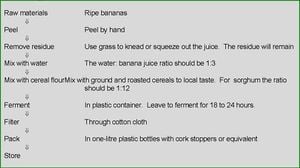

Ripe bananas (Musa spp.) are selected. In the rainy season, unripe bananas can be placed on a hurdle over the cooking fire to ripen. During the dry season, bananas can be encouraged to ripen by placing them in a pit in the ground and covering them with banana leaves and soil. A small trench for a fire should be dug on one side of the pit to allow heat and smoke to enter the pit. This takes about six days. The bananas should then be peeled. If the banana peels cannot be removed by hand, the bananas are not ripe enough.

Processing

The first step is to prepare the banana juice. The extraction of a high-yielding banana juice without excessive browning or contamination by fermentable microorganisms and adequate filtration to produce a clear product is of great importance. Grass can be used to squeeze the banana so only a clear juice is obtained. The residue will remain in the grass. Volume of water should be added to every three volumes of banana juice. This makes the total soluble volume low enough for the yeast to act. Cereals are ground and roasted and added to enhance the color and flavor of the end product. The mixture is placed in a container, which is covered in polyethylene to ferment for eighteen to twenty-four hours. Green material preparations are not sterilized by boiling and therefore provide an excellent substrate for microbial growth. It is crucial that proper hygienic procedures are followed and that contaminating bacteria are sterilized from competing with the yeast and the production of acid, that all equipment is thoroughly in place of the alcohol. This can be done by cleaning with boiling water or with chlorine solution. The prudence is necessary to wash the equipment free of residual chlorine, as this would interfere with the actions of the yeast. Strict personal hygiene is also crucial. For many traditional fermented products, the microorganisms responsible for fermentation are unknown to scientists. However, there has been research to identify microorganisms involved in banana beer. The main microorganism is Saccharomyces Cerevisiae which is the same organism that is involved in making grape juice wine. However, many other microorganisms have been identified. This varies accordingly for the region of production. After fermentation, the product is filtered through cotton cloth.

Packing and filing

Packaging is usually only required to hold the product for the relatively short shelf life. Clean glass or plastic bottles should be used. The product should be kept in a cool place away from direct sunlight.

Reference and literature

Grape Wine, Practical Action Technical Brief

Banana Fries, Practical Action Technical Brief

Traditional Food: Processing for Profit, Edited by Pete Fellows, ITDG Publications 1997

Organizations and Contacts

CTA

PO Box 380

6700 AJ Wageningen

The Netherlands

Telephone: +31 (0) 317 467100

Fax: +31 317 460 067

E-mail: cta@cta.nl

Website: http://www.agricta.org/

Horticulture and Landscape Architecture website , Perdue University

http://www.hort.purdue.edu/newcrop/morton/banana.html